Method for removing alkaline dross chloride ions through surfactant

A surfactant and chloride ion technology, applied in the field of comprehensive utilization of alkali slag, can solve the problems that alkali slag cannot be recycled on a large scale and chloride ions are reduced, and achieve the effect that large-scale regeneration cannot be used, the effect is good, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Utilize surfactant to remove alkali slag chloride ion, specifically comprise the following steps:

[0024] (1) After mixing the mixture of alkali slag, sodium hexametaphosphate and sodium citrate (sodium hexametaphosphate: sodium citrate=4:1, w / w) and water in a mass ratio of 100:2:300, Put it into a mixer and stir for 15 minutes at a speed of 76 rpm to prepare a uniform slurry;

[0025] (2) Then the slurry is filtered through a filter press for 10 minutes at a pressure of 0.2 MPa, the filter cake is taken out, and the filter cake is put into an oven to dry to a constant weight to obtain a chlor-alkali removal slag.

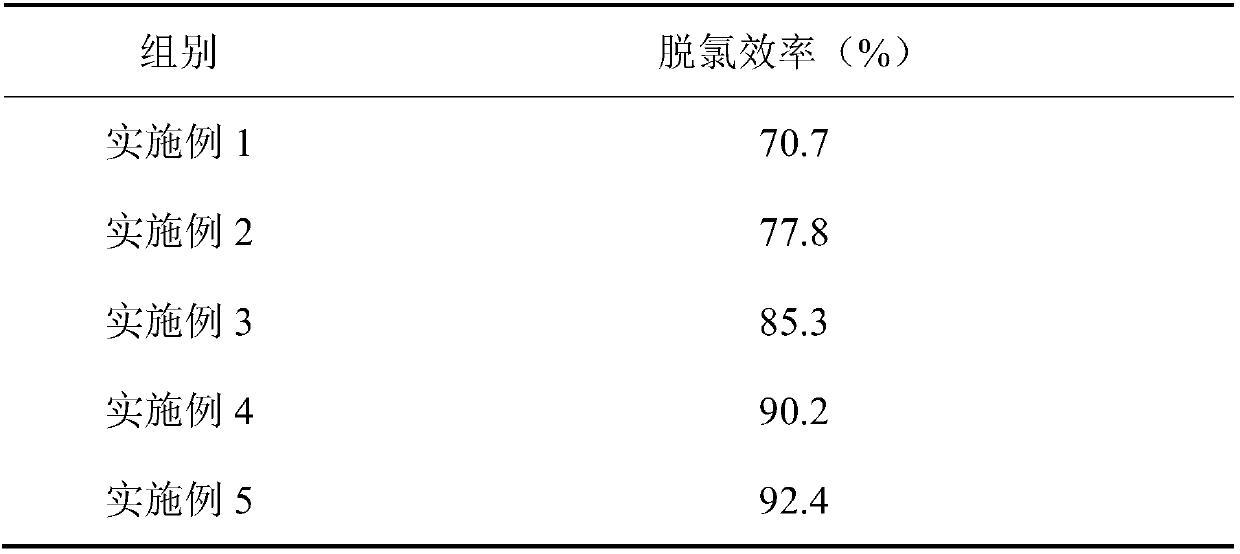

[0026] The chlorine removal effect of alkali slag is shown in Table 1.

Embodiment 2

[0028] Utilize the method for removing alkali slag chlorine ion by surfactant, specifically comprise the following steps:

[0029] (1) After mixing the mixture of alkali slag, sodium hexametaphosphate and sodium citrate (sodium hexametaphosphate: sodium citrate=4:1, w / w) and water in a mass ratio of 100:4:300, Put it into a mixer and stir for 10 minutes at a speed of 80 rpm to prepare a uniform slurry;

[0030] (2) Filter the slurry through a filter press for 30 minutes at a pressure of 0.1 MPa, take out the filter cake, put the filter cake in an oven and dry it to a constant weight to obtain a chlor-alkali removal slag.

[0031] The chlorine removal effect of alkali slag is shown in Table 1.

Embodiment 3

[0033] Utilize surfactant to remove alkali slag chloride ion, specifically comprise the following steps:

[0034] (1) The mixture of alkali slag, sodium ethylenediamine tetramethylene phosphonate and sodium tripolyphosphate (sodium ethylenediamine tetramethylene phosphonate: sodium tripolyphosphate=3:1, w / w) and After the water is mixed evenly according to the mass ratio of 100:10:400, it is put into a mixer and stirred for 15 minutes at a speed of 84 rpm to prepare a uniform slurry;

[0035] (2) Filter the slurry through a filter press for 20 minutes at a pressure of 0.3 MPa, take out the filter cake, put the filter cake in an oven and dry it to a constant weight to obtain a chlor-alkali removal slag.

[0036] The chlorine removal effect of alkali slag is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com