Cobalt-Based Catalysts for the Synthesis of Methyl Isobutyl Ketone from Acetone

A technology of methyl isobutyl ketone and cobalt-based catalysts, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, and the preparation of organic compounds, and can solve the problem of inability to produce or by-product 4-methyl-2-pentanol, etc. problems, to achieve the effect of easy manipulation, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

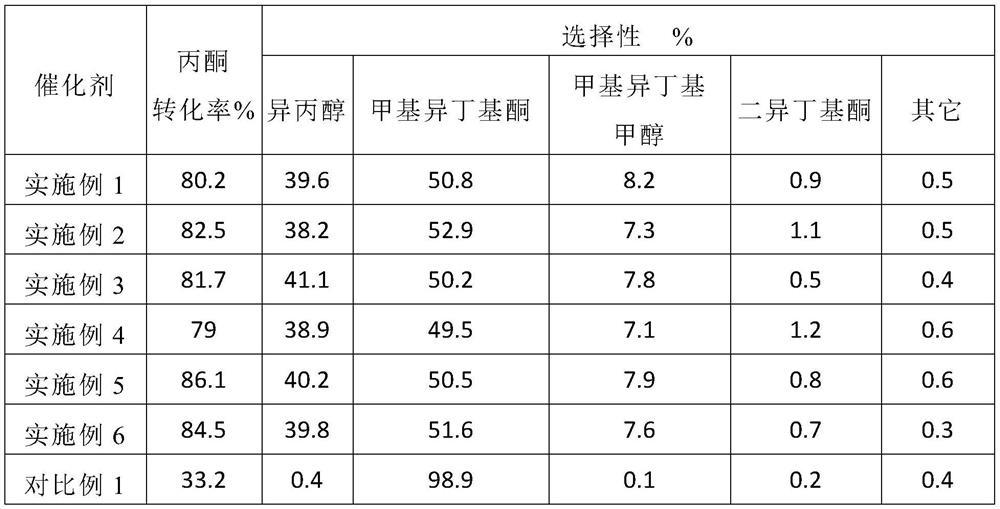

Examples

Embodiment 1

[0037] 133.4 grams of cobalt nitrate and 4.7 grams of ammonium fluoride were dissolved in 322 grams of water in a beaker to prepare aqueous solution I. In another beaker, 74.1 grams of sodium stannate was dissolved in 173 grams of water to make aqueous solution II. Under stirring and at 70° C., the sodium stannate aqueous solution II was poured into the beaker of the aqueous solution I, and then titrated with 30 wt % sodium carbonate aqueous solution until the pH value of the reaction solution was 7.5. Then add 332 grams of pseudo-boehmite powder. Pseudoboehmite is produced by Jiangsu Sanji Industrial Co., Ltd., with a specific surface area of 305m 2 / g, the pore volume is 0.92mL / g.

[0038] Then aged at 70° C. for 4 hours, then suction filtered and washed until the sodium ion content was lower than 0.05%. The wet filter cake was dried, granulated, and then roasted and decomposed at 400°C. Finally, it is sliced into granules, and the particle size is

[0039] Then...

Embodiment 2

[0044] 88.9 grams of cobalt nitrate and 0.66 grams of sodium fluoride were dissolved in 208 grams of water in a beaker to prepare aqueous solution I. In another beaker, 101.1 g of sodium stannate was dissolved in water to make aqueous solution II. With stirring and at 70° C., the sodium stannate aqueous solution II was poured into the beaker of the aqueous solution I, and then titrated with 30 wt % sodium carbonate aqueous solution until the pH value of the reaction solution was 7.4. Then add 325 grams of pseudo-boehmite powder. Pseudoboehmite is produced by Jiangsu Sanji Industrial Co., Ltd., with a specific surface area of 298m 2 / g, the pore volume is 1.0mL / g.

[0045] Then aged at 75° C. for 3 hours, then suction filtered and washed until the sodium ion content was lower than 0.05%. The wet filter cake was dried, granulated, and then roasted and decomposed at 380°C. Finally, it is sliced into granules, and the particle size is

[0046] Then, the catalyst was r...

Embodiment 3

[0049] 177.9 grams of cobalt nitrate and 2.3 grams of ammonium fluoride were dissolved in 420 grams of water in a beaker to prepare aqueous solution I. In another beaker, 148.3 grams of sodium stannate was dissolved in 350 grams of water to make aqueous solution II. Under stirring and at 73° C., the sodium stannate aqueous solution II was poured into the beaker of the aqueous solution I, and then titrated with 30 wt % sodium carbonate aqueous solution until the pH value of the reaction solution was 7.2. Then add 266 grams of pseudo-boehmite powder. Pseudoboehmite is produced by Jiangsu Sanji Industrial Co., Ltd., with a specific surface area of 279m 2 / g, the pore volume is 0.88mL / g.

[0050] Then aged at 75° C. for 3.5 hours, then suction filtered and washed until the sodium ion content was lower than 0.05%. The wet filter cake was dried, granulated, and then roasted and decomposed at 370°C. Finally, it is sliced into granules, and the particle size is

[0051] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com