Method for degrading VOCs via normal temperature catalytic oxidation

A catalytic oxidation, room temperature technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high energy consumption, easy generation of by-products, etc., and achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

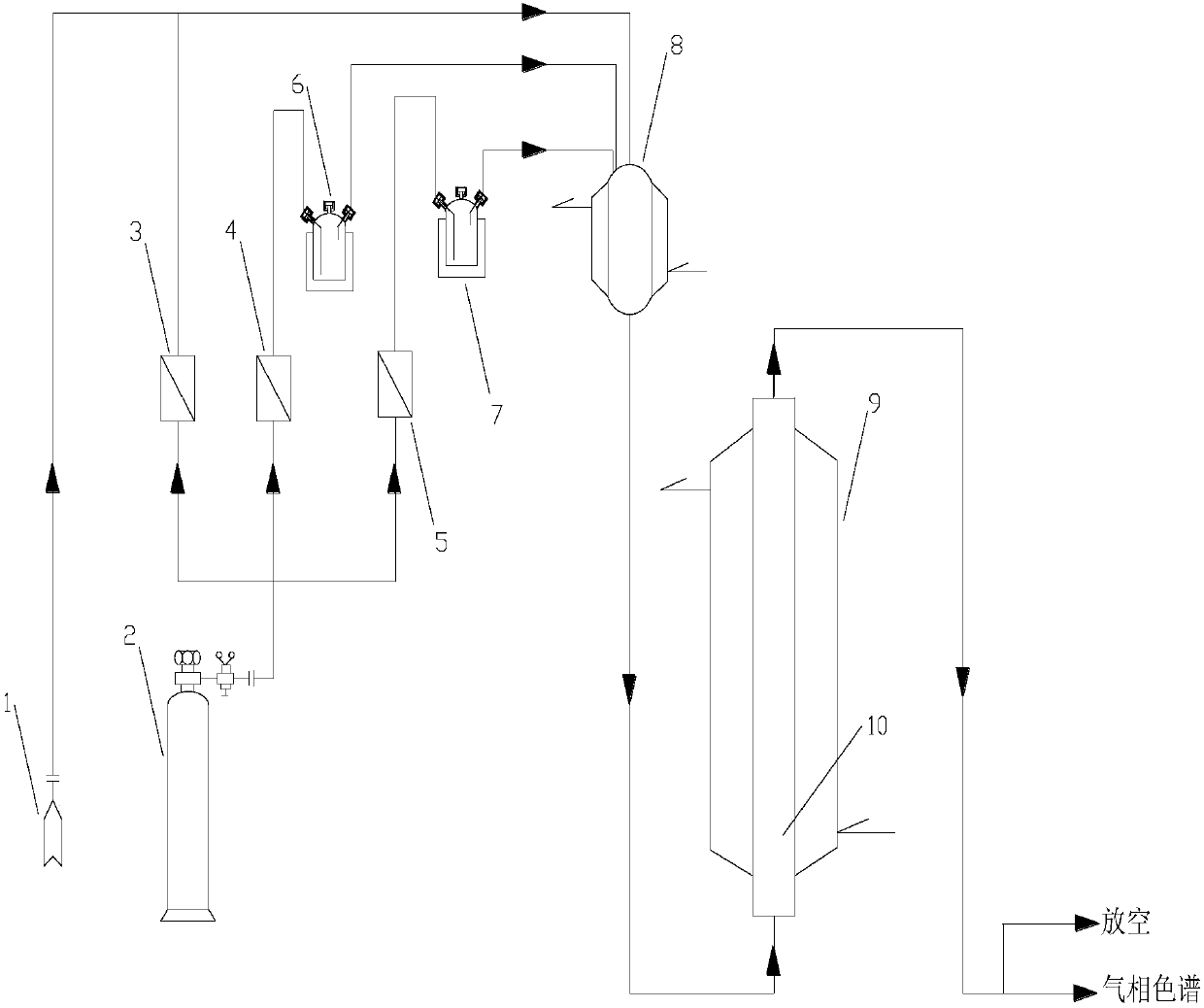

Method used

Image

Examples

Embodiment 1

[0030] The nitrogen provided by the nitrogen cylinder is divided into three paths, one is through the VOCs blow-off bottle, the flow rate is controlled at 20mL / min, the other is nitrogen as a buffer gas, the flow rate is controlled at 900mL / min, and the other is through the water vapor bubbling bottle, the flow rate is controlled at 25mL / min, controlled by a mass flow meter. The methylene chloride liquid is filled in the VOCs blow-off bottle. The temperature of the water vapor bubbling bottle is controlled at 20° C.; the temperature of the VOCs blow-off bottle is controlled at 15° C. The ozone concentration that described ozone generator provides is 1000ppm, and flow control is 1000mL / min, is controlled by rotameter. The concentration of VOCs in the mixer is 800ppm.

[0031] After the ozone is mixed with the nitrogen buffer gas, it enters the mixer together with the nitrogen containing VOCs and the nitrogen containing water vapor for mixing. After the mixing is complete, it ...

Embodiment 2

[0038] The nitrogen provided by the nitrogen cylinder is divided into three paths, one is through the VOCs blow-off bottle, the flow rate is controlled at 1mL / min, the other is nitrogen as a buffer gas, the flow rate is controlled at 100mL / min, and the other is through the water vapor bubbling bottle, the flow rate is controlled at 1mL / min, controlled by a mass flow meter. Ethyl acetate liquid is filled in the described VOCs blow-off bottle. The temperature of the water vapor bubbling bottle is controlled at 0°C; the temperature of the VOCs blow-off bottle is controlled at -10°C. The ozone concentration that described ozone generator provides is 200ppm, and flow control is 100mL / min, is controlled by rotameter. The concentration of VOCs in the mixer is 100ppm.

[0039]After the ozone is mixed with the nitrogen buffer gas, it enters the mixer together with the nitrogen containing VOCs and the nitrogen containing water vapor for mixing. After the mixing is complete, it enters ...

Embodiment 3

[0046] The nitrogen provided by the nitrogen cylinder is divided into three paths, one is through the VOCs blow-off bottle, the flow rate is controlled at 30mL / min, the other is nitrogen as a buffer gas, the flow rate is controlled at 1000mL / min, and the other is through the water vapor bubbling bottle, the flow rate is controlled at 50mL / min, controlled by a mass flow meter. Fill the toluene liquid in the described VOCs blow-off bottle. The temperature of the water vapor bubbling bottle is controlled at 40°C; the temperature of the VOCs blow-off bottle is controlled at 40°C. The ozone concentration that described ozone generator provides is 2000ppm, and flow control is 2500mL / min, is controlled by rotameter. The concentration of VOCs in the mixer is 1000ppm.

[0047] After the ozone is mixed with the nitrogen buffer gas, it enters the mixer together with the nitrogen containing VOCs and the nitrogen containing water vapor for mixing. After the mixing is complete, it enters ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com