Continuous countercurrent extraction process and extraction system for reconstituted tobacco raw material stems

A technology of reconstituted tobacco leaves and countercurrent extraction, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, etc., can solve the problem of inability to meet production and manufacturing capacity, clean production capacity, physical and chemical control capacity, inability to realize automatic control of extraction process, and unstable quality of reconstituted tobacco leaves, etc. problems, to achieve the effect of reducing human interference, simple and easy-to-control extraction process, stable quality and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

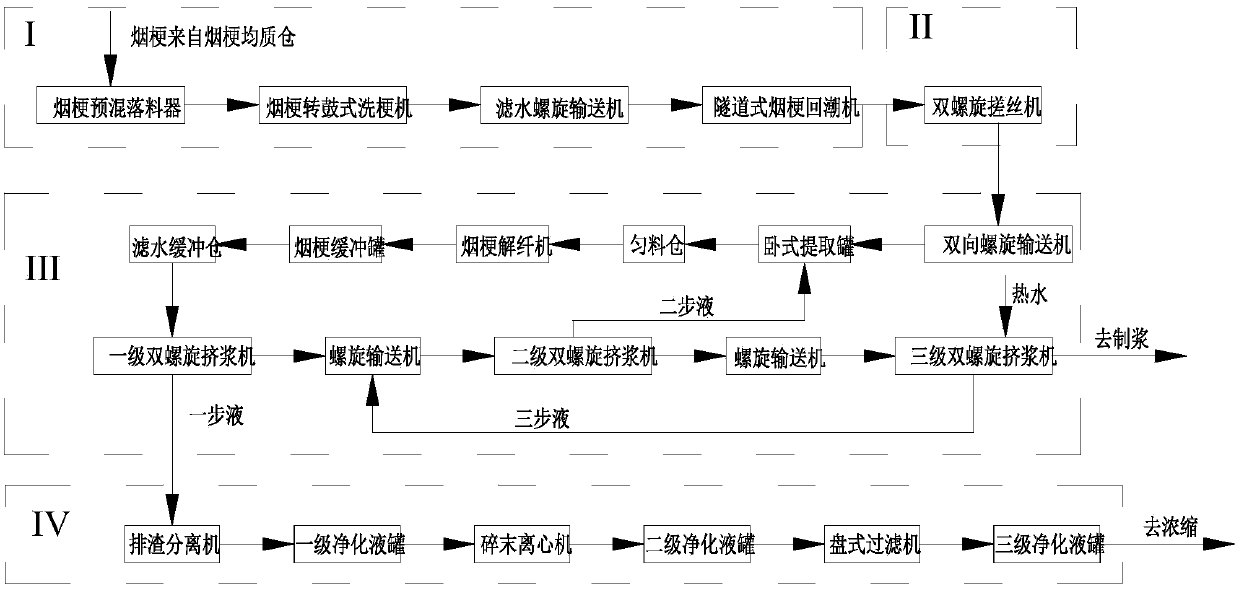

[0035] The continuous countercurrent extraction process of raw material tobacco stems of reconstituted tobacco leaves, such as figure 1 shown, including the following:

[0036] Step 1: Pretreatment of Tobacco Stems

[0037] The measured tobacco stem raw materials are sent to the drum type stem washing machine for stem washing; after washing the stems, they are sent to the tobacco stem dampening machine through the water filter screw conveyor, and the tobacco stems are swelled at 70-80°C to complete Pretreatment of tobacco stems; after the pretreatment is completed, the moisture content of tobacco stems increases by 2% to 5%;

[0038] Step 2 Ⅱ: Coarse Fiber Decomposition of Tobacco Stems

[0039] Put the pretreated tobacco stem raw material into the double-helix thread rolling machine, and break the cell wall of the tobacco stem through rubbing to achieve the purpose of accelerating extraction;

[0040] Step 3 III: Extraction and solid-liquid separation

[0041] Send the to...

Embodiment 2

[0045] The continuous countercurrent extraction process of raw material tobacco stems of reconstituted tobacco leaves, such as figure 1 shown, including the following:

[0046] Step 1: Pretreatment of Tobacco Stems

[0047] The measured tobacco stem raw materials are sent to the drum type stem washing machine for stem washing; after washing the stems, they are sent to the tobacco stem dampening machine through the water filter screw conveyor, and the tobacco stems are swelled at 70-80°C to complete Pretreatment of tobacco stems; after the pretreatment is completed, the moisture content of tobacco stems increases by 2% to 5%;

[0048] Step 2 Ⅱ: Coarse Fiber Decomposition of Tobacco Stems

[0049] Put the pretreated tobacco stem raw material into the double-helix thread rolling machine, and break the cell wall of the tobacco stem through rubbing to achieve the purpose of accelerating extraction;

[0050] Step 3 III: Extraction and solid-liquid separation

[0051] Send the to...

Embodiment 3

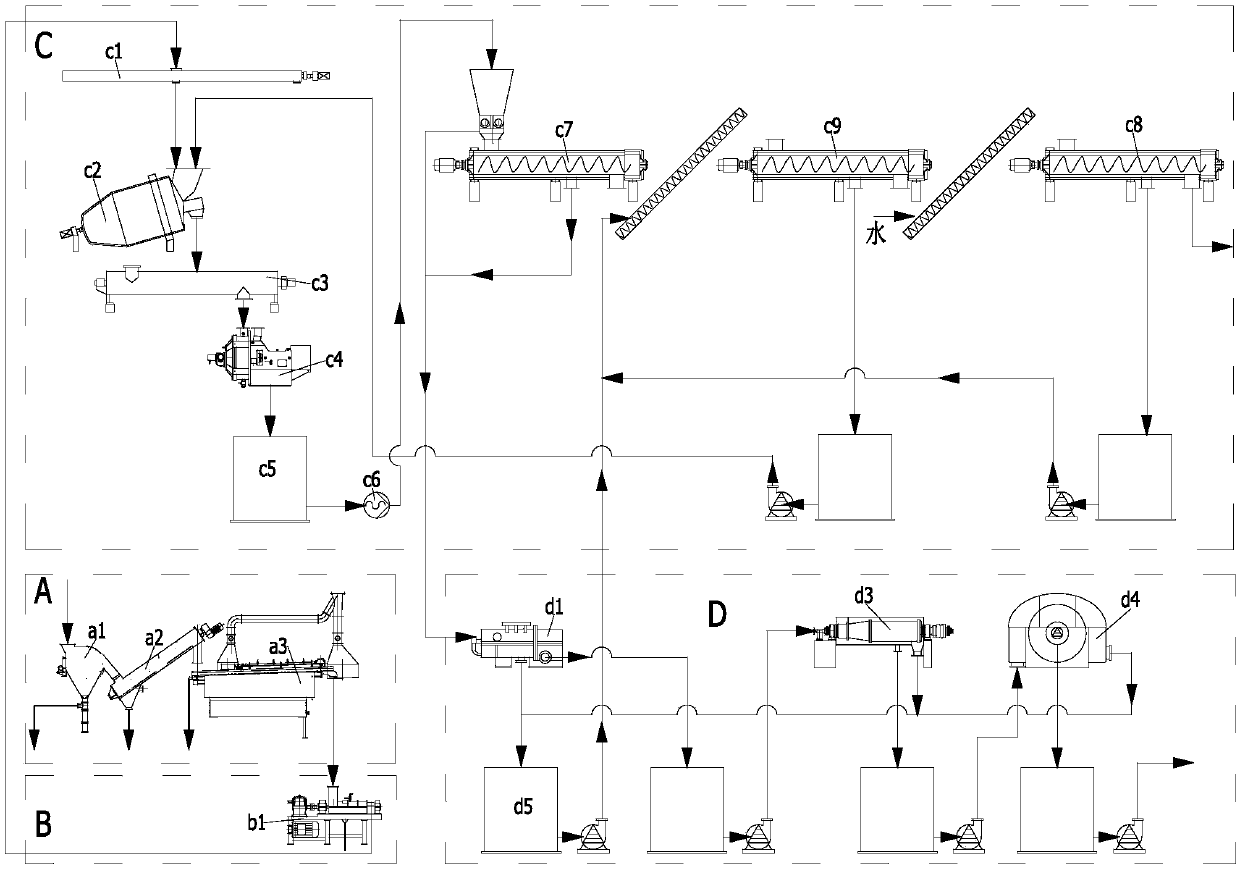

[0055] figure 2 The extraction system for the raw material tobacco stems of reconstituted tobacco leaves shown includes pretreatment equipment A, fiber roughing equipment B, extraction and solid-liquid separation equipment C, and extraction liquid purification equipment D;

[0056] The pretreatment equipment A includes a drum type stem washing machine a1 for receiving tobacco stems and washing the stems, a tobacco stem dampening machine a3 for rehydrating the tobacco stems, and a material row between the input end and the drum type stem washing machine a1. The water filter screw conveyor a2 is connected to the outlet, and the output end is connected to the material inlet of the tobacco stem reconditioning machine a3;

[0057] The fiber roughing equipment B includes a double-helix thread rolling machine b1 that connects the material inlet to the material outlet of the tobacco stem reconditioning machine a3;

[0058] The extraction and solid-liquid separation equipment C inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com