Nutrient strengthened feed additive as well as preparation technology and application thereof

A feed additive and preparation process technology, which is applied in the molding or processing, application, animal feed and other directions of animal feed, can solve the problems of hindering the digestion, absorption and utilization of nutrient elements, high cost, and increase in the amount of feed added, so as to protect the nutrients. , the effect of promoting degradation and improving digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of DHA Nutritional Enhanced Feed Additive

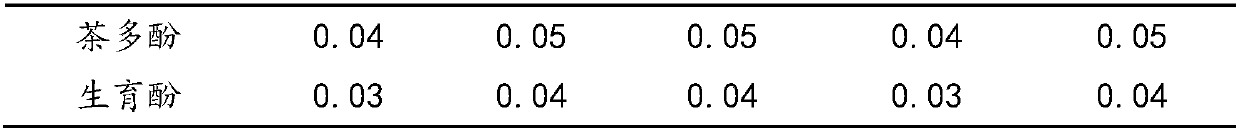

[0034] It mainly includes: mix the non-mildew and complete linseed with 0.5% iron-free calcium chloride aqueous solution at a mass ratio of 1:6, adjust the pH value of the mixed material to 4, and pour it into a high-pressure hydrothermal reaction kettle , Cover the lid of the reaction kettle, connect the vacuum pump through the gas outlet above the liquid level, and vacuum for 5 minutes to remove oxygen. Then close the outlets of the reactor, heat to 100°C, open the outlet of the reactor to deflate for 30 seconds, and then start the hydrothermal pretreatment. The hydrothermal pretreatment conditions are: temperature 100°C, treatment time 60 minutes, stirring speed 60 rpm, initial pH value 7. After the treatment is completed, quickly deflate and cool down to 90°C, and after solid-liquid separation, wash the linseed with deionized water once. The schizontium algae powder and the pretreated flaxseed were mixed in a...

Embodiment 2

[0036] Preparation of ARA Nutritional Enhanced Feed Additive

[0037] It mainly includes: mixing evenly the mildew-free and complete evening primrose seeds with 1% iron-free calcium chloride aqueous solution at a mass ratio of 1:10, adjusting the pH value of the mixed material to 5 and pouring it into high-pressure hydrothermal reaction In the kettle, cover the lid of the reaction kettle, connect the vacuum pump through the gas outlet above the liquid level, and vacuumize for 5 minutes to remove oxygen. Then close the outlets of the reactor, heat to 100°C, open the outlet of the reactor to deflate for 30 seconds, and then start the hydrothermal pretreatment. The hydrothermal pretreatment conditions are temperature of 120°C, treatment time of 30 minutes, stirring speed of 150 rpm, and initial pH value of 7. After the treatment, quickly deflate and cool down to 90°C. After solid-liquid separation, wash the evening primrose seeds with water once. Mortierella alpina thalline and...

Embodiment 3

[0039] Preparation of γ-Linolenic Acid-Squalene-DHA Nutritional Enhancement Feed Additive

[0040] It mainly includes: mixing the mildew-free and complete perilla seeds with 0.8% iron-free calcium chloride aqueous solution at a mass ratio of 1:10, adjusting the pH value of the mixed material to 5 and pouring it into high-pressure hydrothermal reaction In the kettle, cover the lid of the reaction kettle, connect the vacuum pump through the gas outlet above the liquid level, and vacuumize for 5 minutes to remove oxygen. Then close the outlets of the reactor, heat to 100°C, open the outlet of the reactor to deflate for 30 seconds, and then start the hydrothermal pretreatment. The hydrothermal pretreatment conditions were as follows: a temperature of 150° C., a treatment time of 10 minutes, a stirring speed of 150 rpm, and an initial pH value of 7. After the treatment, the temperature is quickly released to 90°C, and after solid-liquid separation, the perilla seeds are washed onc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com