Cooling system for electronic device

A technology for cooling systems and electronic equipment, which is applied to structural parts of electrical equipment, cooling/ventilation/heating renovation, circuits, etc., can solve problems such as leakage of synthetic oil, and achieve the effect of efficient absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

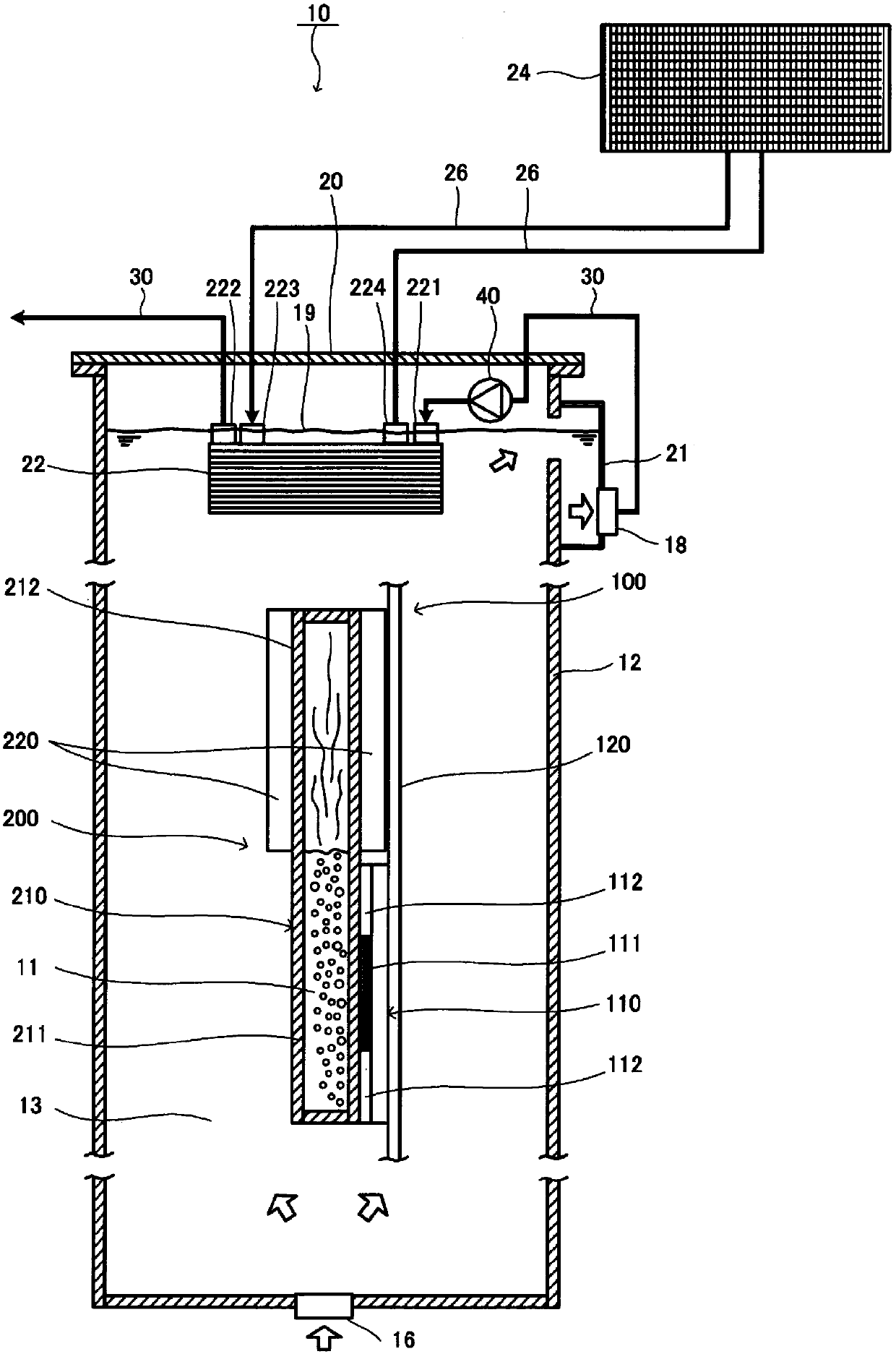

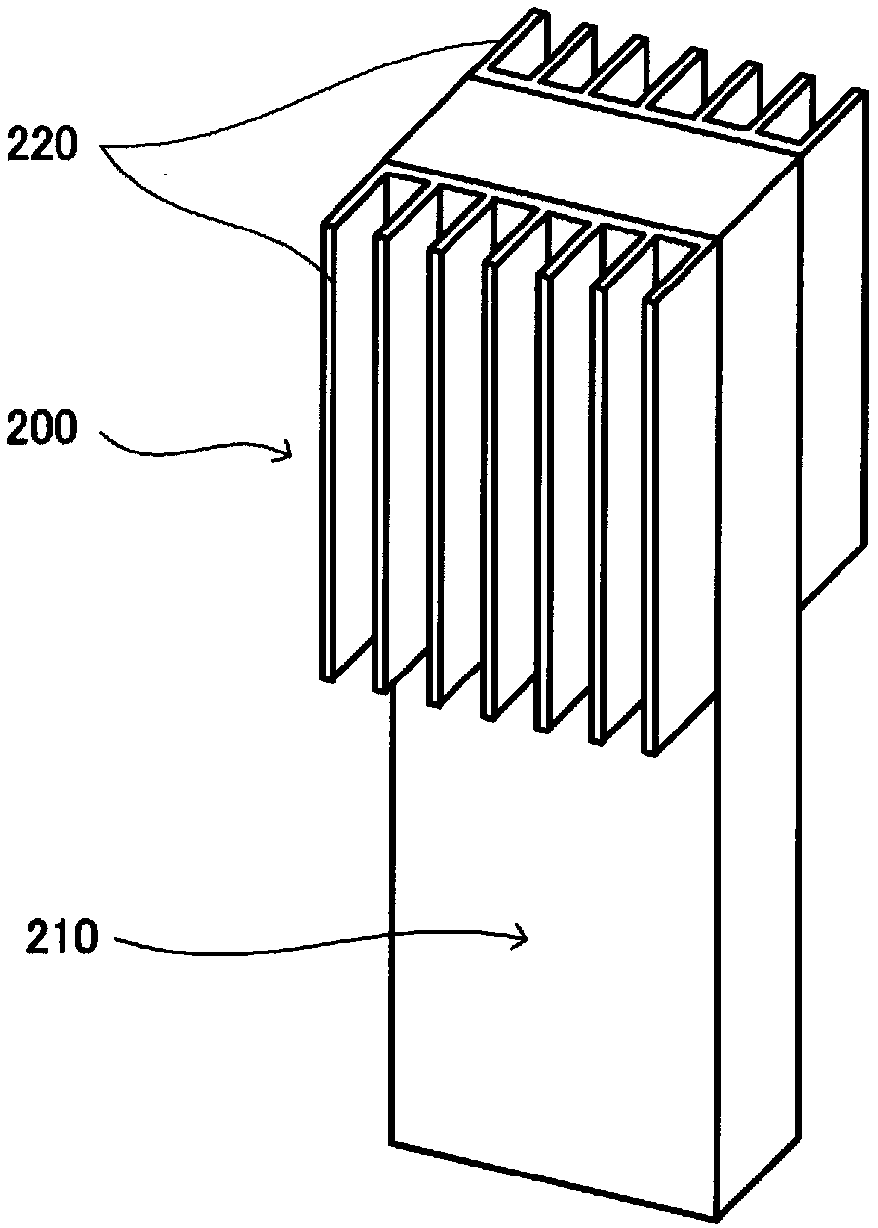

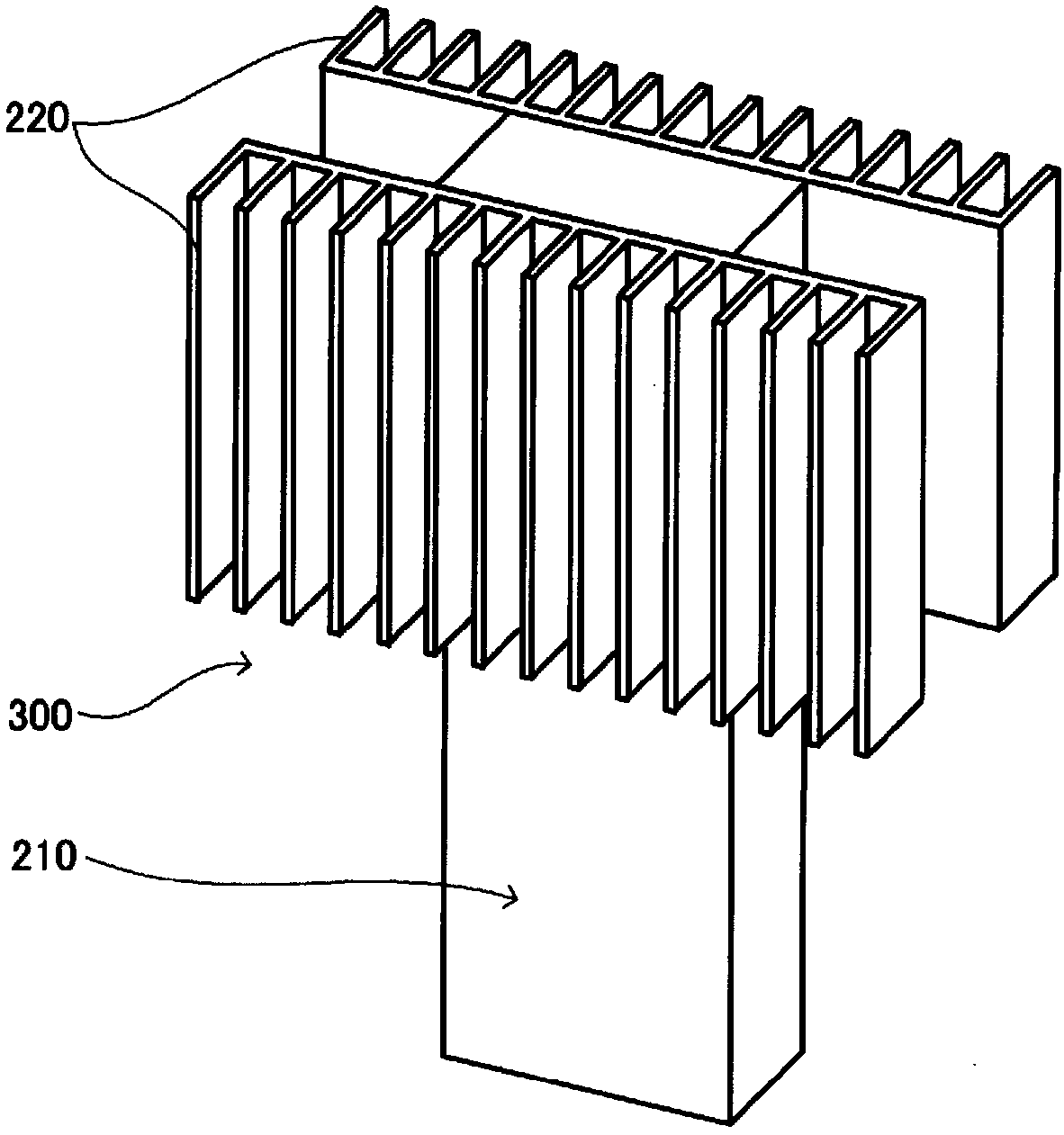

[0048] Hereinafter, preferred embodiments of the cooling system of the present invention will be described in detail based on the drawings. In the description of this embodiment, first, for a preferred embodiment, refer to figure 1 , Figure 2A , Figure 2B as well as Figure 2C The structure of the main part of the cooling system is explained as follows: a processor consisting of a bare chip (semiconductor chip) and a heat sink surrounding the bare chip is mounted on the board of the electronic device as a heat generating body, and the electronic device is housed in a cooling tank inside and allow to cool. Next, refer to image 3 as well as Figure 4 A preferred configuration example of the first heat exchanger will be described. Next, for a preferred embodiment, refer to Figure 5 , as an electronic device, only one unit including a board on which a plurality of processors is mounted is briefly shown, and the overall structure of a cooling system for accommodating and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com