Direct borohydride fuel cell capable of simultaneously treating organic wastewater

A borohydride and fuel cell technology, applied in the direction of fuel cells, fuel cell components, circuits, etc., can solve problems such as affecting the output performance of the battery, and achieve the effects of improving fuel utilization, avoiding wear, and reducing polarization loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

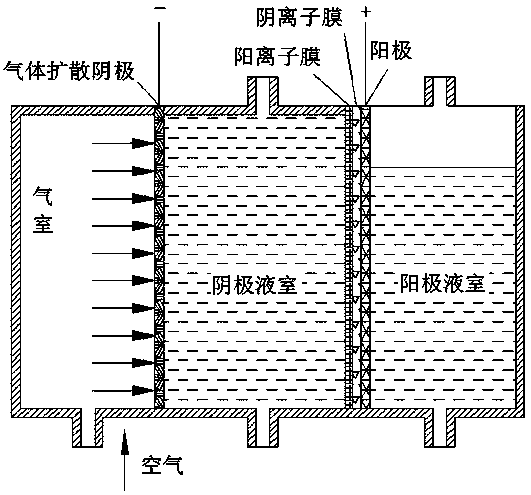

Image

Examples

Embodiment 1

[0044] (1) Weigh 1.0 g of Vulcan XC-72 carbon powder, add 40 mL of a mixture of water and isopropanol with a volume ratio of 1:1, sonicate for 30 min, and sequentially add 0.5 mol / L chloroauric acid solution and CuSO 4 solution, control the molar ratio of Au and Cu to 0.2:1, ultrasonically vibrate for 1 hour, then add enough sodium borohydride solution to reduce, stir at a constant temperature of 80 ° C for 1 hour, suction filtration, rinse with distilled water to obtain a metal content of 40% AuCu / C catalyst. Take 0.5 g of carbon-supported catalyst AuCu / C, add 10 mL of anhydrous ethanol and 3 mL of Nafion solution, sonicate for 30 min, and evenly coat it on the nickel mesh so that the metal loading on the nickel mesh is 1 mg / cm 2 . Drying is the anode of the prepared battery.

[0045] (2) Take 1g of activated carbon fiber, add 7mL of acetone, ultrasonically shake for 10 minutes to make an ink-like mixture, then add 0.05g of 10% PTFE, stir, ultrasonically shake for 70 minute...

Embodiment 2

[0052] (1) Weigh 1.0 g of Vulcan XC-72 carbon powder, add 40 mL of a mixture of water and isopropanol with a volume ratio of 1:1, sonicate for 30 min, and add 0.5 mol / L chloroauric acid solution and NiCl in turn 2 solution, control the molar ratio of Au and Ni to 0.5:1, ultrasonically vibrate for 1 hour, then add enough sodium borohydride solution to reduce, stir at a constant temperature of 80 °C for 1 hour, suction filtration, rinse with distilled water to obtain a metal content of 20% AuNi / C catalyst. Take 0.5 g of carbon-supported catalyst AuNi / C, add 10 mL of anhydrous ethanol and 3 mL of Nafion solution, sonicate for 30 min, and coat it on a nickel mesh so that the metal loading on the nickel mesh is 0.5 mg / cm 2 . Drying is the anode of the prepared battery.

[0053] (2) Take 1g of graphite powder, add 10mL of acetone, ultrasonically shake for 10 minutes to make an ink-like mixture, then add 0.2g of 30% PTFE, stir, and ultrasonically shake for 45 minutes, then place in...

Embodiment 3

[0060] (1) Weigh 1.0 g of Vulcan XC-72 carbon powder, add 40 mL of a mixture of water and isopropanol with a volume ratio of 1:1, sonicate for 30 min, and add 0.5 mol / L chloroauric acid solution and CoCl in turn 2 Solution, control the molar ratio of Au to Co to 0.3:1, ultrasonically vibrate for 1h, then add enough sodium borohydride solution to reduce, stir at a constant temperature of 80 °C for 1h, suction filtration, rinse with distilled water to obtain a metal content of 30% AuCo / C catalyst. Take 0.5 g of carbon-supported catalyst AuCo / C, add 10 mL of anhydrous ethanol and 3 mL of Nafion solution, sonicate for 30 min, and coat it on a nickel mesh so that the metal loading on the nickel mesh is 1.5 mg / cm 2 . Drying is the anode of the prepared battery.

[0061] (2) Take 1g of carbon nanotubes (CNTs), add 8mL of acetone, ultrasonically shake for 10 minutes to make an ink-like mixture, then add 0.35g of 50% PTFE, stir, ultrasonically shake for 90 minutes, and place in a 60°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com