Silicone rubber composite material for SLS (selective laser sintering), preparation method of composite material and application of composite material

A technology of composite materials and silicone rubber, applied in the direction of additive processing, etc., can solve the problems of limited polymer materials, high hardness, and poor flexibility, achieve good electrical conductivity and electromagnetic properties, improve laser sintering performance, and broaden the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

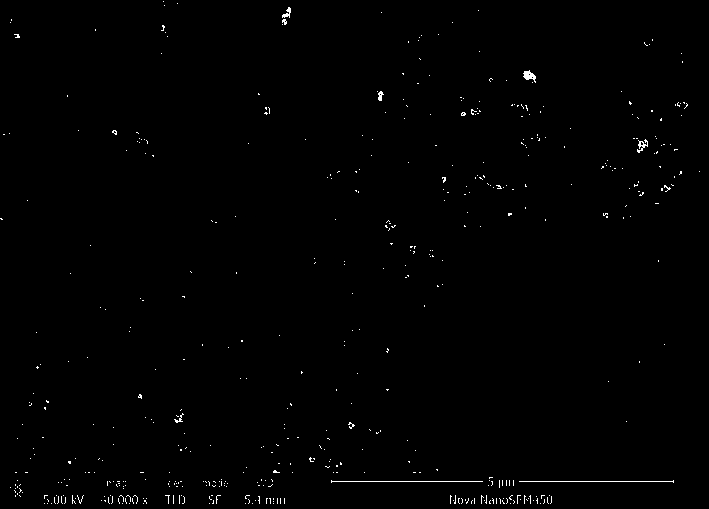

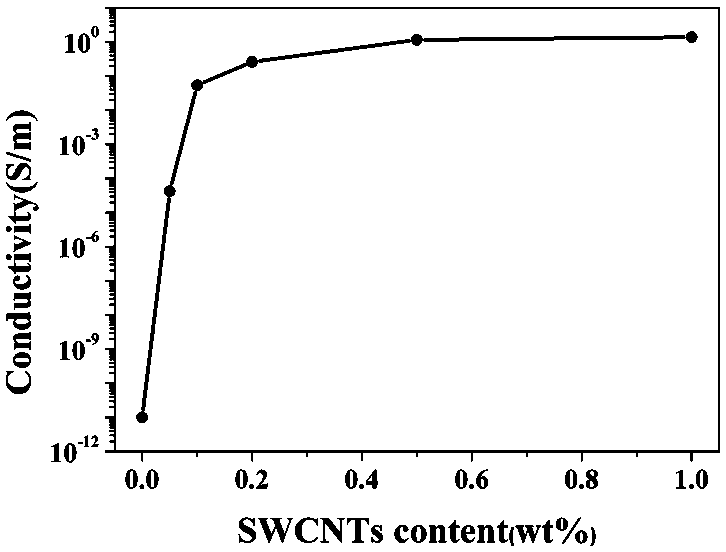

[0030] 100 parts of silicone rubber, 0.1 parts of single-walled carbon nanotubes, 0.1 parts of 2,4-dihydroxybenzophenone, 0.1 parts of 2,6-tertiary butyl-4-methylphenol, 0.1 parts of diallyl After the bisphenol A is melted and mixed, it is added to mechanical grinding equipment including a ball mill, a grinding disc structure pulverizer, etc., and the silicone rubber composite material powder with an average particle size of 10 μm is obtained after pulverization.

Embodiment 2

[0032] 100 parts of silicone rubber, 2 parts of multi-walled carbon nanotubes, 0.2 parts of 2,4-dihydroxybenzophenone, 0.2 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propane Acid] pentaerythritol ester, 0.2 parts of bis (2-ethylhexyl) phthalate melted and mixed and then added to the freeze pulverizer, freeze pulverized to obtain a silicone rubber composite powder with an average particle size of 40 μm.

Embodiment 3

[0034] Prepare 100 parts of silicone rubber into a silicone rubber emulsion, 3 parts of carbon black, 0.2 parts of 5-chlorinated benzotriazole, 0.3 parts of N,N'-bis-(3-(3,5-di-tert-butyl- 4-Hydroxyphenyl) propionyl) hexamethylenediamine, 0.3 parts of diethylene glycol dibenzoate powder are added to the emulsion, the emulsion is added to the spray drying equipment, the solution is sprayed under high pressure, and hot air contact, remove the solvent to obtain a silicone rubber composite material powder with an average particle size of 70 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com