Material and method for preparing LED bracket through imprint lithography technology

A technology of LED bracket and lithography technology, which is applied in the fields of opto-mechanical equipment, optics, and photo-engraving process of pattern surface, which can solve the problem of waste of energy consumption of bracket materials and materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

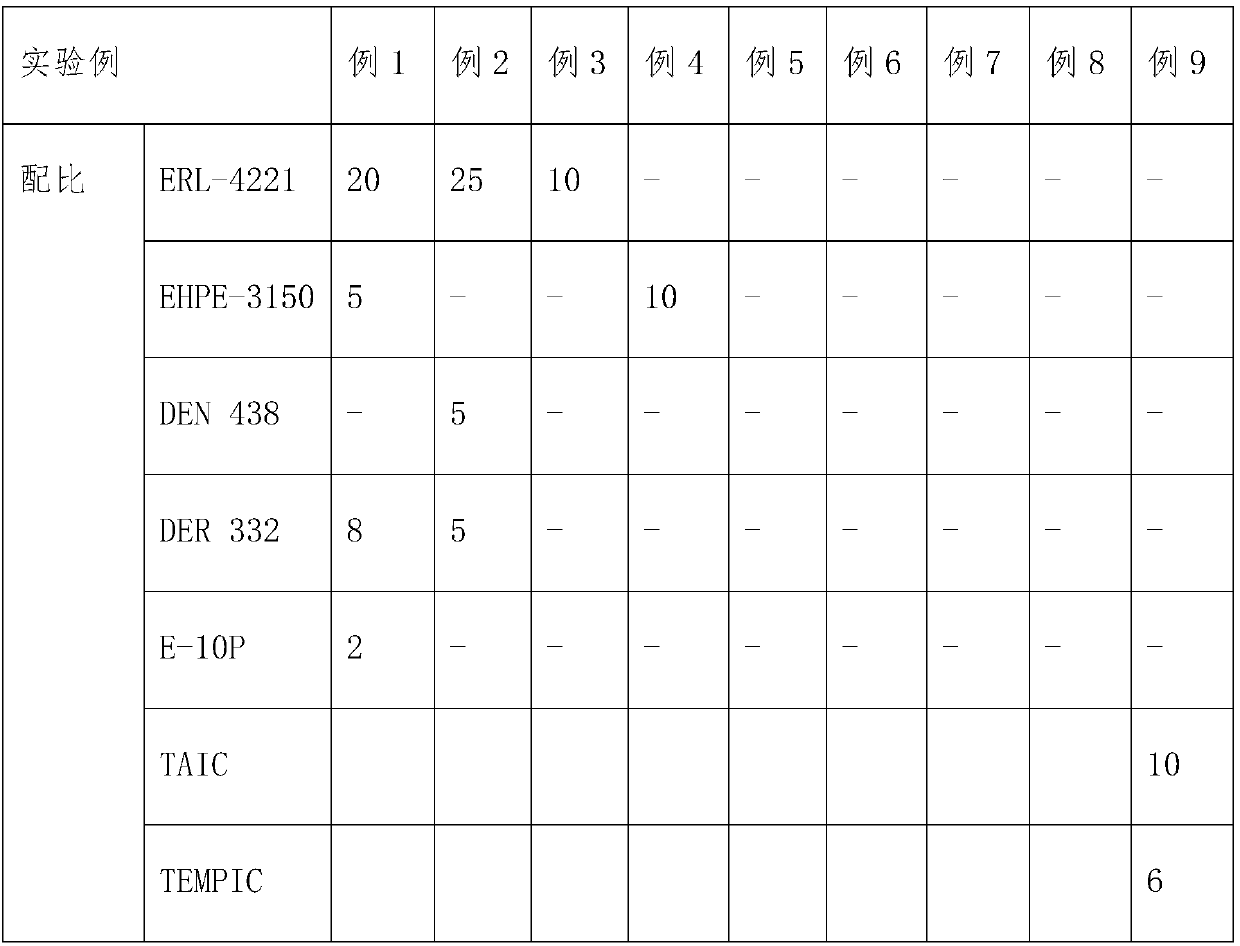

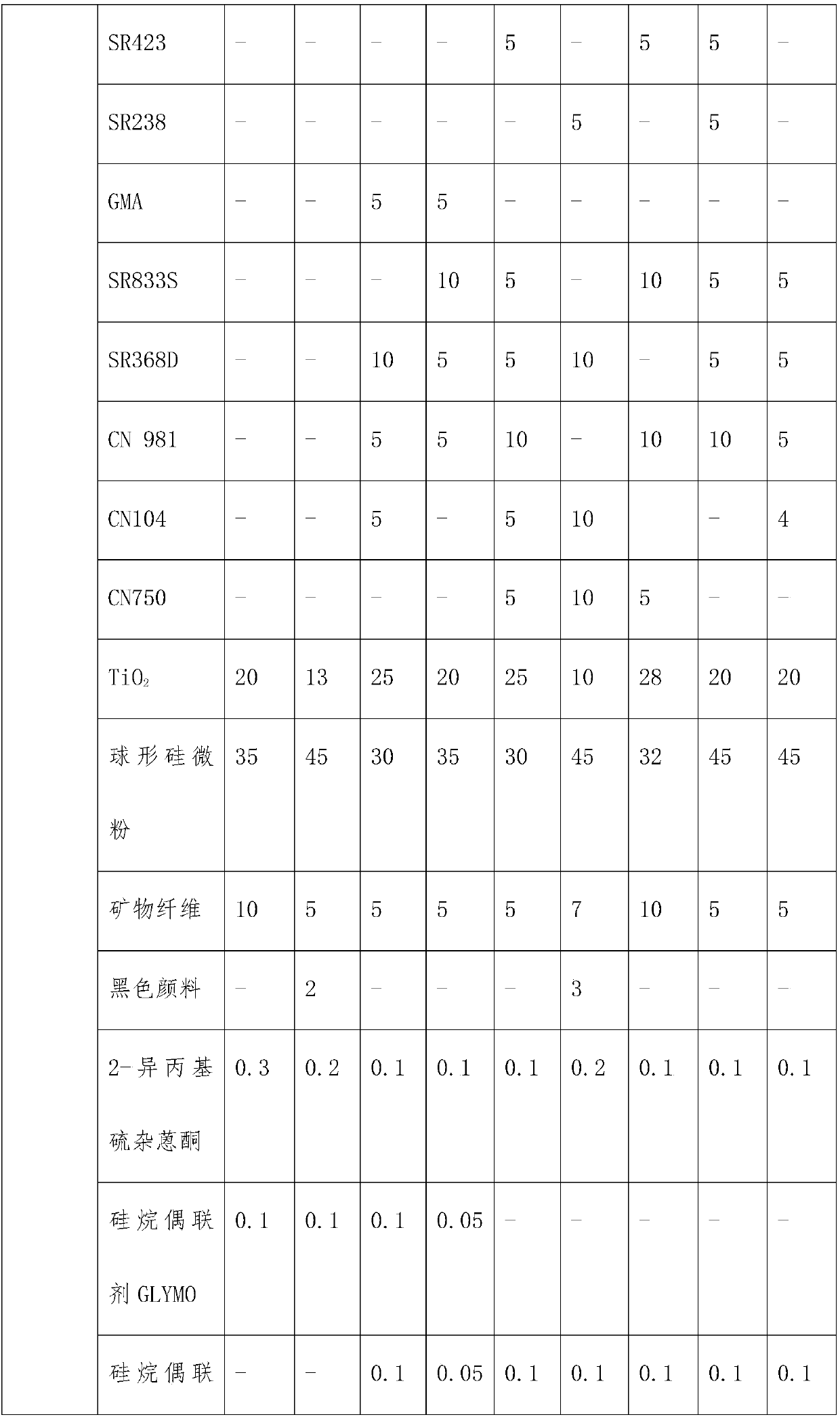

[0038] Hereinafter, the present invention will be specifically described by showing examples, but the present invention is not limited to the following examples.

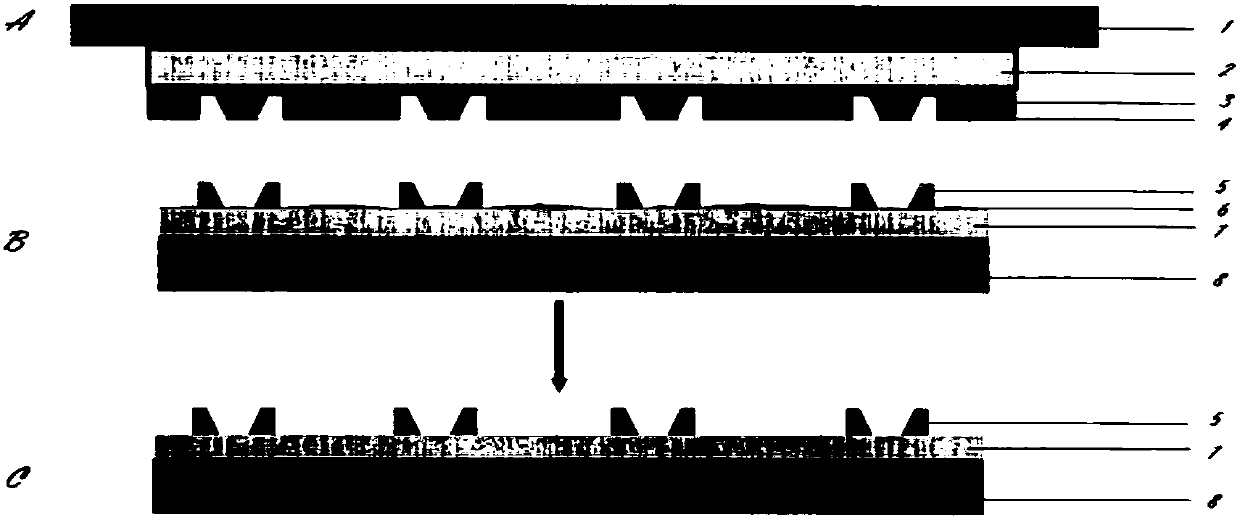

[0039] refer to figure 1 , a method for preparing LED brackets by imprint lithography technology, using imprint lithography equipment, coating and curing imprint glue on printed circuit boards (PCB) or pins. The imprint lithography equipment includes a flexible composite mold A (1-4), a carrier table 8, and pneumatic, electric, vacuum, and electrostatic systems. Embossing glue is a liquid or solid material, including resin, filler, functional additives, photosensitive additives and curing components.

[0040] Such as figure 1 As shown in A, the flexible composite mold A is adsorbed on the electronically controlled manipulator by vacuum; figure 1 As shown in B, the pins to be processed or the PCB board are installed on the sample carrier 8 .

[0041] Apply embossing glue to pins or PCB boards by one or more metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com