Method and device for optimal operation control of boiler heater

A technology for optimizing operation and control methods, applied in the direction of controlling combustion, combustion methods, indirect carbon dioxide emission reduction, etc., can solve problems such as large steam consumption, unconsidered air preheater blockage, increased coal consumption of heater power generation, etc., and achieve thermal efficiency High efficiency, guaranteed operation economy and guaranteed equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

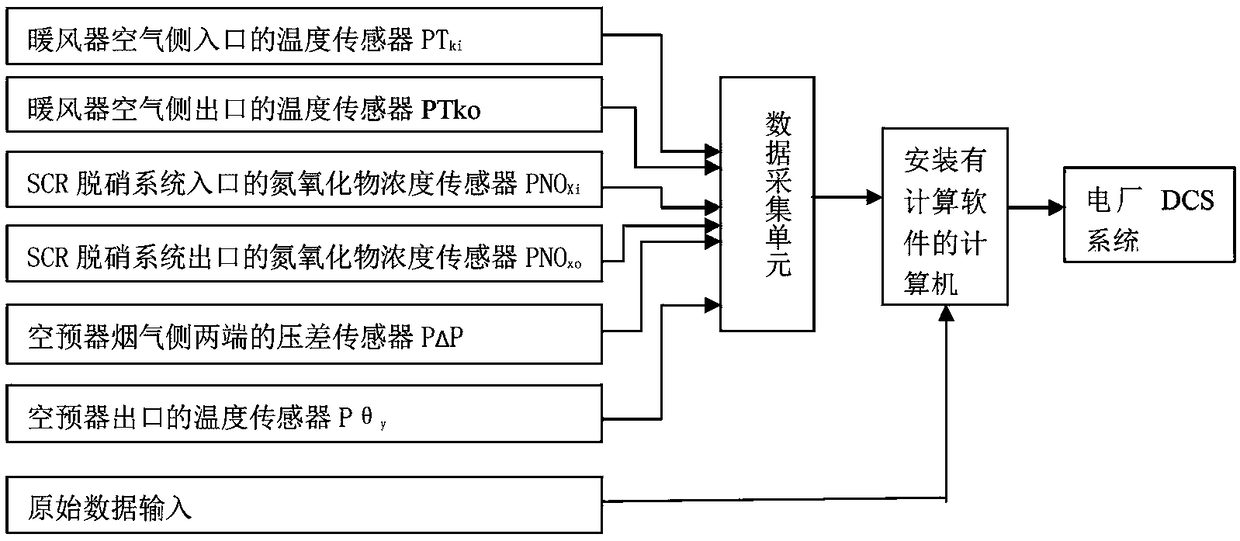

[0029] A boiler heater optimization operation control device, including a temperature sensor PT installed at the air side inlet of the boiler heater ki , The temperature sensor PT installed at the air side outlet of the heater ko , The nitrogen oxide concentration sensor PNO installed at the inlet of the boiler SCR denitrification system Xi , The nitrogen oxide concentration sensor PNO installed at the outlet of the boiler SCR denitrification system Xo, The differential pressure sensor PΔP installed at both ends of the flue gas side of the boiler air preheater, the temperature sensor Pθ installed at the outlet of the flue gas side of the air preheater y , a data acquisition unit and a computer with Visual Basic software installed; the temperature sensor PT ko , temperature sensor PT ki , Nitrogen oxide concentration sensor PNO Xi , Nitrogen oxide concentration sensor PNO Xo , differential pressure sensor PΔP and temperature sensor Pθ y The output ends of the data acquisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com