Coal cutter cutting part with differential speed separation roller

A technology of shearer cutting part and separation drum, which is applied in the field of coal mining machinery, can solve the problems of low coal throwing speed of the drum, serious floating coal, and influence on the movement of the support, and achieve good axial fluidity, small motor volume, The effect of good coal loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

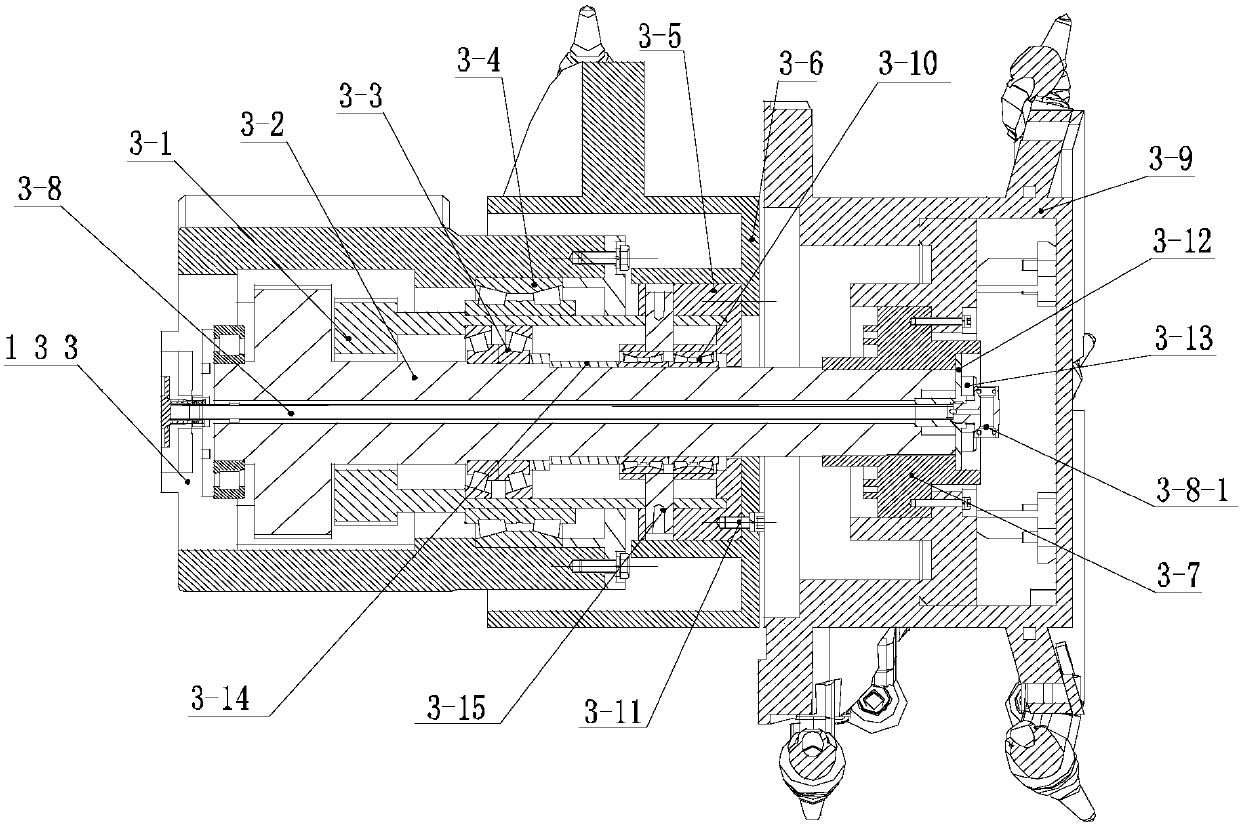

[0035] Such as figure 1 Shown is a shearer cutting section with a differential separation drum, including a cutting section box, a motor drive section, a gear transmission section, and a drum output section;

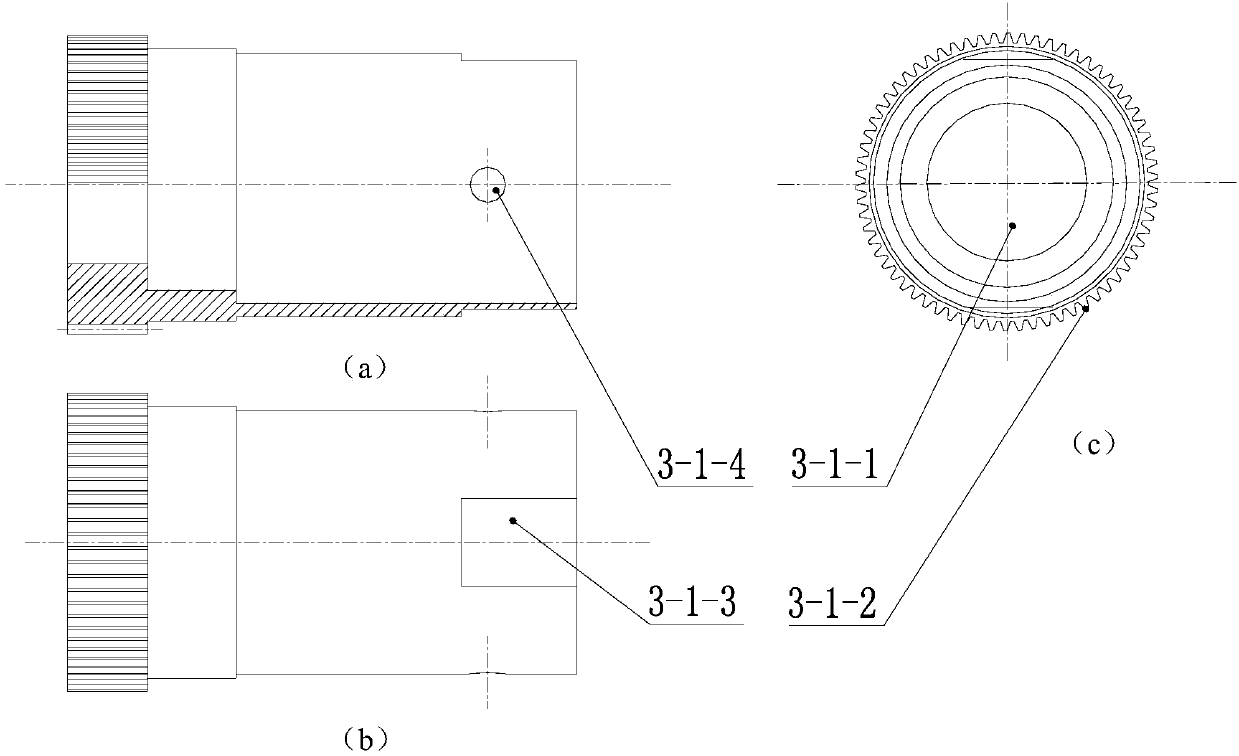

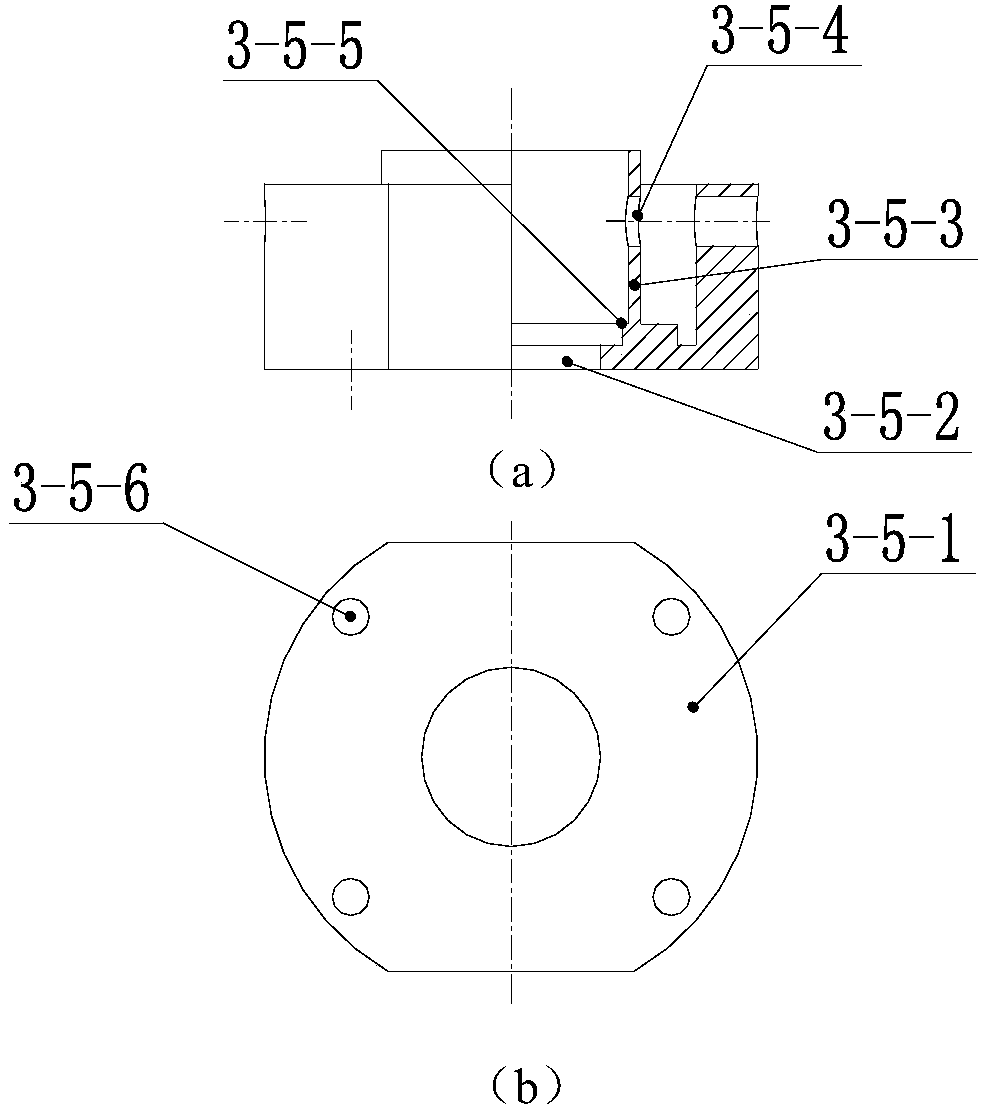

[0036] Wherein, the cutting part of the shearer is driven by double motors, and the motor driving part includes a left cutting motor and a right cutting motor, both of which are arranged in the cutting part box; A plurality of shaft holes, the shaft hole is covered with an end cover; the gear transmission part includes the left gear shaft, idler one, right gear shaft, idler two, main input shaft, planetary reduction gear arranged in the cutting part box Mechanism, primary gear shaft, secondary gear shaft, input gear, output gear, tertiary optical shaft, fixed speed gear, speed distribution shaft, main gear, secondary gear, bearing seat, bearing bearing group; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com