Floor ground heating device and installing method thereof

A floor and floor heating technology, which is applied in the field of floor heating devices, can solve the problems of non-environmental protection, waste of energy, waste of materials, etc., and achieve the effects of prolonging service life, saving energy, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

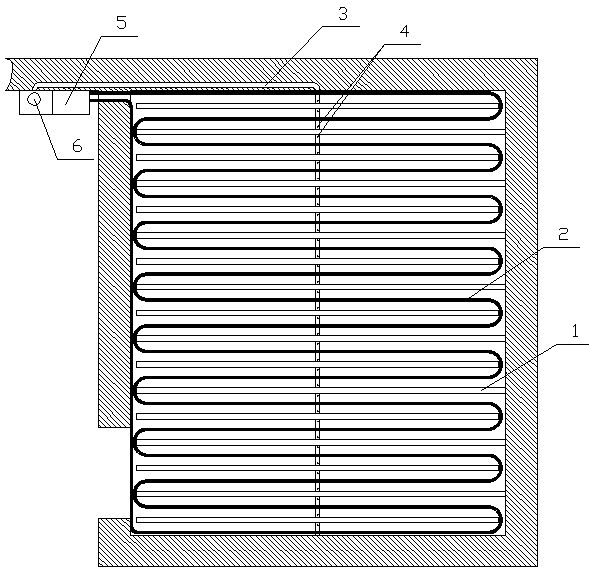

[0016] Implementation case one; a floor heating device, including a floor, a ground ridge 1, a heater 5 and a heating body 2. A heating body 2 is provided between the ground ridge 1 and the ground ridge 1, and the heating body 2 is connected to the heater 5 to heat The body 2 is provided with at least one jet pipe 3 in the vertical direction, the heater 5 is a water heater, and the heating body 2 is a hot water pipe. The jet pipe 3 is provided with jet holes 4 on both sides of the hot water pipe, and one end of the jet pipe 3 is connected with Blower 6, the other end is blocked; when installing, slot the floor where the jet pipe 3 is laid, so that the jet pipe 3 is level with the floor, and then lay the ground ridge 1 according to the requirements of the floor, such as the jet pipe 3 above the ground The ground ridge 1 is slotted at the intersection with the jet pipe 3. If the jet pipe 3 is already level with the ground when laying, the ground ridge 1 does not need to be grooved...

Embodiment example 2

[0017] Implementation case two; other things are the same as above, heater 5 is an electric heater, heating body 2 is a silica gel heating belt or carbon fiber heating belt, or there is no gap between the floor and the wall, the floor and the skirting, which can also achieve rapid heating and The effect of underfloor heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com