Magnesium alloy surface micro arc oxidation ceramic layer hole sealing agent and hole sealing method

A technology of micro-arc oxidation and magnesium alloy, which is applied in anodic oxidation, metal material coating process, coating, etc., can solve the problems of unsatisfactory sealing effect and complexity, achieve easy operation of sealing process and improve corrosion resistance , Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

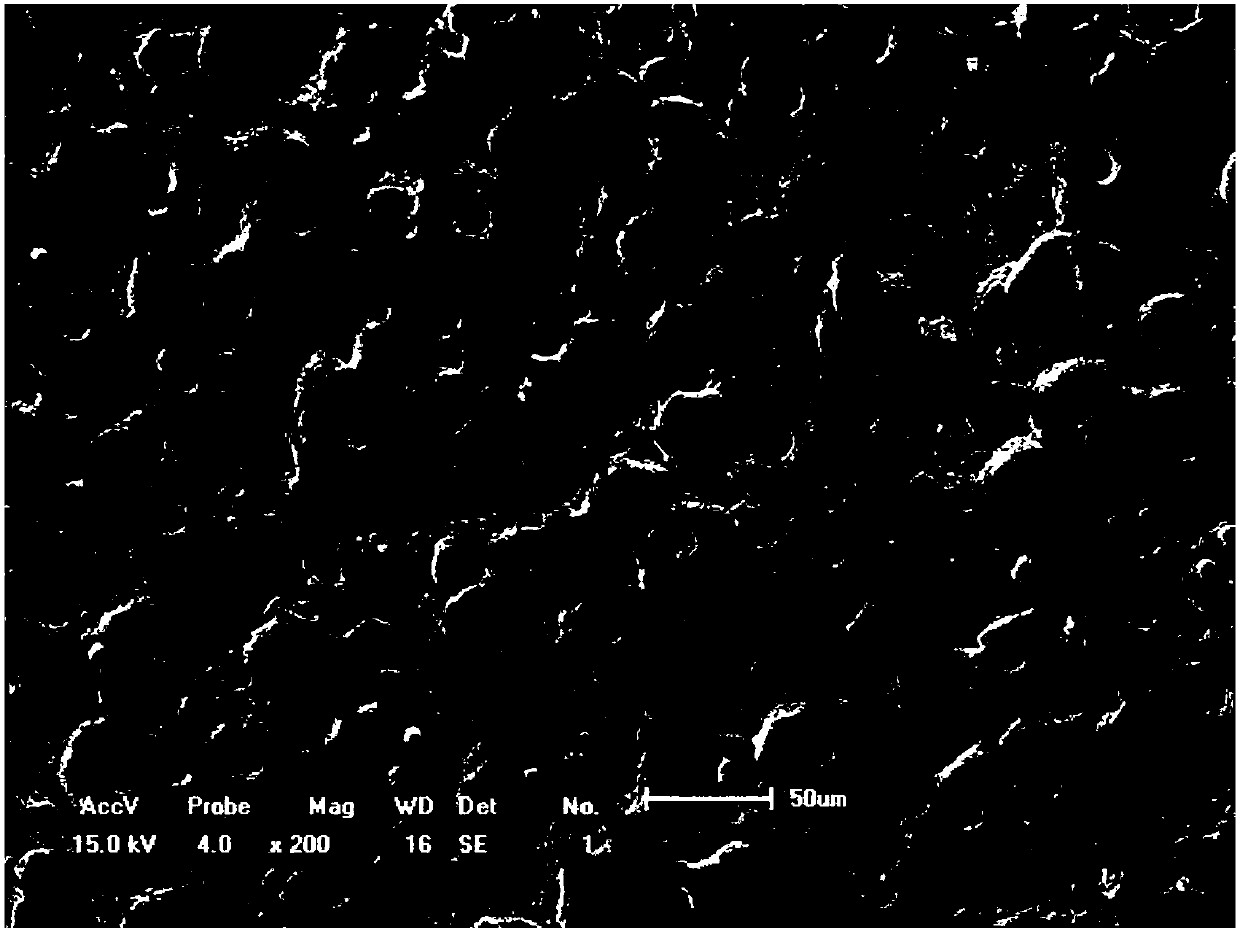

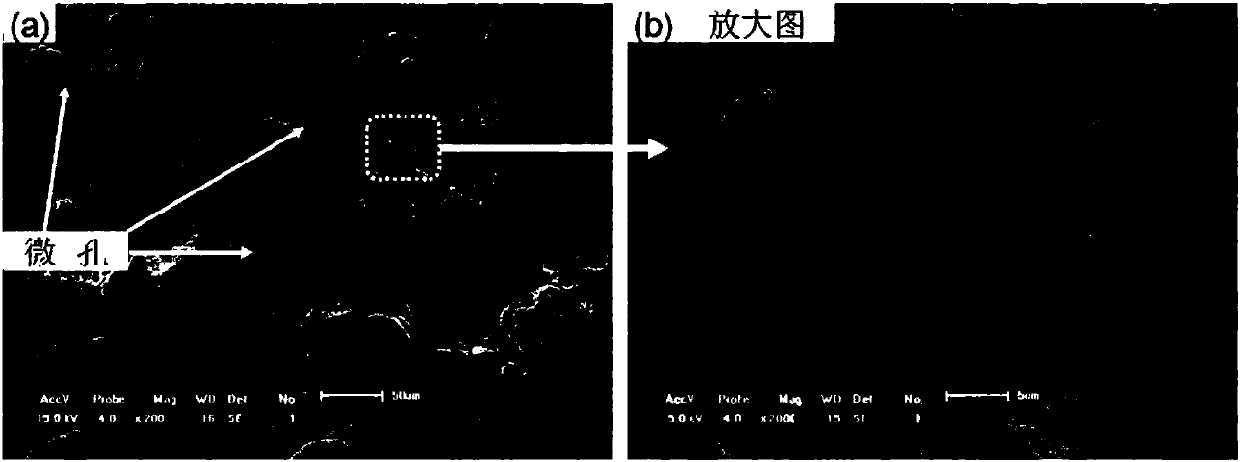

[0021] Wherein, the sodium stearate, sodium metaaluminate and sodium dodecylbenzenesulfonate can all be analytical reagents. The preparation method of the micro-arc oxidation ceramic layer on the surface of the magnesium alloy may include: placing the magnesium alloy in an electrolyte solution containing graphene for micro-arc oxidation treatment, the time of the micro-arc oxidation treatment is 10 to 60 minutes, and the output voltage is 350 to 300 minutes. 500V, the duty ratio of the power supply is 30-60%, so as to prepare the micro-arc oxidation ceramic layer on the surface of the magnesium alloy; wherein, the electrolyte containing graphene is composed of the following raw materials in parts by weight: 10-20 parts of sodium silicate , 5-10 parts of potassium hydroxide, 1-5 parts of sodium dodecylbenzenesulfonate, and 0.05-0.1 parts of graphene.

[0022] Specifically, the sealing method for the micro-arc oxidation ceramic layer on the surface of the magnesium alloy provide...

Embodiment 1

[0030] A micro-arc oxidation ceramic layer sealing agent on the surface of a magnesium alloy, which is prepared by uniformly mixing the following raw materials in parts by weight: 10 parts of sodium stearate, 10 parts of sodium metaaluminate, and 2 parts of sodium dodecylbenzenesulfonate , 28 parts of ethanol with a mass fraction of 98%, and 50 parts of deionized water.

[0031]Specifically, a magnesium alloy workpiece whose size is 30mm × 30mm × 5mm is placed in an electrolyte solution containing graphene (by weight, the electrolyte solution containing graphene consists of 10 parts of sodium silicate, hydroxide 5 parts of potassium, 2 parts of sodium dodecylbenzenesulfonate and 0.05 parts of graphene) carry out micro-arc oxidation treatment, the time of micro-arc oxidation treatment is 30min, the output voltage is 450V, and the duty cycle of power supply is 45%. After the micro-arc oxidation treatment is completed, the magnesium alloy workpiece is taken out, cleaned with deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com