Oxytetracycline tablet production technology

A technology of oxytetracycline tablet and production process, which is applied in the field of production process of oxytetracycline tablet, can solve problems such as low yield of oxytetracycline, long fermentation time, affecting preparation quality and clinical curative effect, etc., and achieves shortening fermentation time, Residue reduction, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

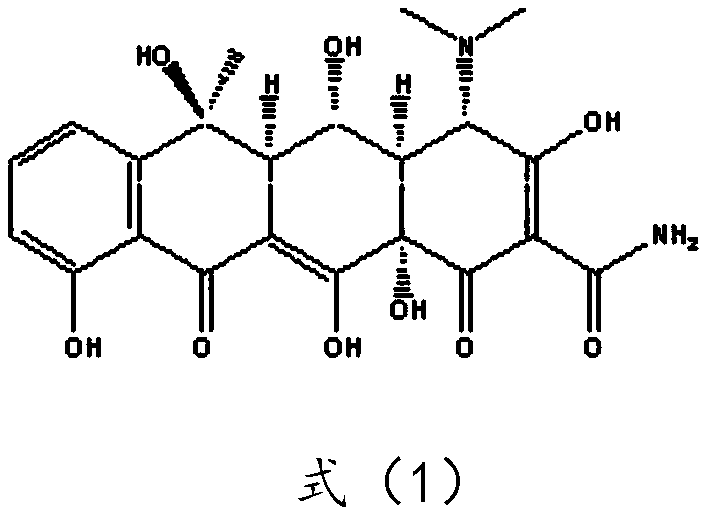

Image

Examples

Embodiment 1

[0043] A kind of production technology of oxytetracycline sheet, specifically comprises the following steps:

[0044] (1) Preparation of fermentation broth;

[0045] Prepare oxytetracycline fermented liquid, select Streptomyces fistidis culture medium for use, the nitrogen source of described Streptomyces crackes culture medium is soybean cake powder, light yellow corn steep liquor, urea and egg white liquid, and carbon source is potato flour, dextrin ;Adopt purebred submerged, aeration and stirring three-stage fermentation culture method,

[0046] a, preparation of slanted spores: culture spore conditions: slanted spores are cultivated at a temperature of 35°C, humidity is 55%, and the incubation time is 96h; then the spores are placed under a deuterium lamp and irradiated for 30s under a 250-300nm ultraviolet light to modify, and the The modified spores are inoculated into the primary seed tank for cultivation;

[0047] b. Primary seed tank cultivation: the cultivation tem...

Embodiment 2

[0067] A kind of production technology of oxytetracycline sheet, specifically comprises the following steps:

[0068] (1) Preparation of fermentation broth;

[0069] Prepare oxytetracycline fermented liquid, select Streptomyces fistidis culture medium for use, the nitrogen source of described Streptomyces crackes culture medium is soybean cake powder, light yellow corn steep liquor, urea and egg white liquid, and carbon source is potato flour, dextrin ;Adopt purebred submerged, aeration and stirring three-stage fermentation culture method,

[0070] a, preparation of slant spores: culture spore conditions: the slant spores are cultivated at a temperature of 38°C, the humidity is 60%, and the cultivation time is 120h; then the spores are placed under a deuterium lamp and irradiated for 60s under a 250-300nm ultraviolet light for modification, and the The modified spores are inoculated into the primary seed tank for cultivation;

[0071] b. Primary seed tank cultivation: the cu...

Embodiment 3

[0091] A kind of production technology of oxytetracycline sheet, specifically comprises the following steps:

[0092] (1) Preparation of fermentation broth;

[0093] Prepare oxytetracycline fermented liquid, select Streptomyces fistidis culture medium for use, the nitrogen source of described Streptomyces crackes culture medium is soybean cake powder, light yellow corn steep liquor, urea and egg white liquid, and carbon source is potato flour, dextrin ;Adopt purebred submerged, aeration and stirring three-stage fermentation culture method,

[0094] a, preparation of slant spores: culture spore conditions: slant spores are cultivated at a temperature of 36°C, humidity is 57%, and the incubation time is 100h; then the spores are placed under a deuterium lamp and irradiated for 50s under a 250-300nm ultraviolet light to modify, and the The modified spores are inoculated into the primary seed tank for cultivation;

[0095] b. Primary seed tank cultivation: the cultivation temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com