Aramid fiber enhanced polypropylene micro-foaming composite material and preparation method thereof

An aramid fiber and composite material technology, which is applied in the field of aramid fiber reinforced polypropylene micro-foamed composite material and its preparation, can solve the problems of reducing the mechanical properties of foamed materials, low relative density, and foaming, and achieves improved fusion. The effect of intensity, inhibition and foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a method for preparing the aramid fiber reinforced polypropylene micro-foaming composite material, comprising the following steps:

[0025] (1) After the aramid fiber is hydrolyzed, the hydrolyzed aramid fiber is obtained, and then in an inert gas protection atmosphere, the hydrolyzed aramid fiber, isocyanate modifier, and catalyst are heated and refluxed in an organic solvent to obtain a modified aramid fiber 1;

[0026] (2) Reacting the modified aramid fiber 1 and the amino-terminating agent in an organic solvent at 60-80°C for 6-8 hours to obtain the modified aramid fiber 2;

[0027] (3) Mix the modified aramid fiber 2, copolymerized polypropylene, compatibilizer, antioxidant, lubricant and auxiliary agent evenly, then put it into the main feed of the twin-screw extruder, and melt and extrude it to produce Granules to obtain polypropylene composite materials;

[0028] (4) Mixing the polypropylene composite material and foaming ag...

Embodiment 1

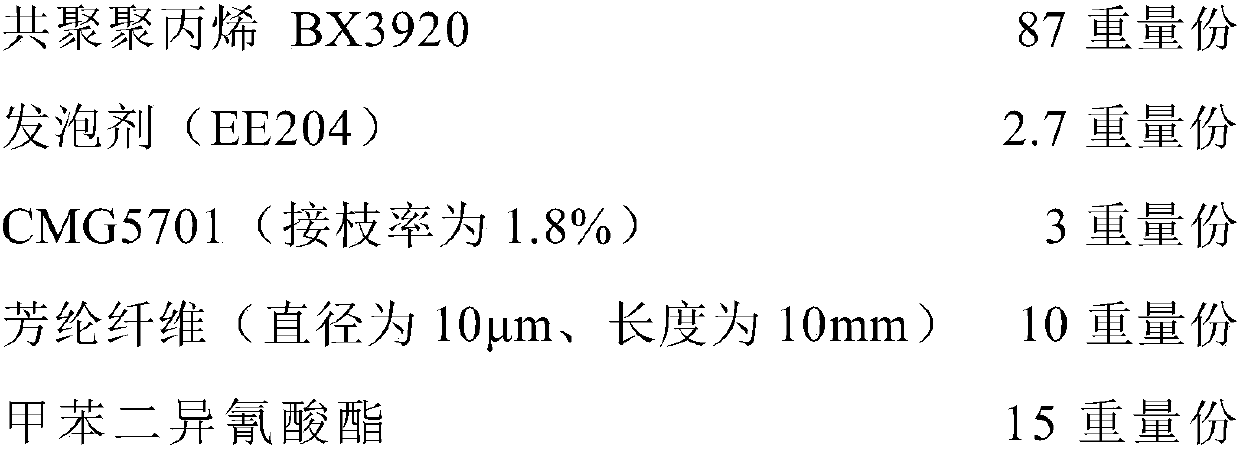

[0036] A kind of aramid fiber reinforced polypropylene micro-foaming composite material is made of the following substances by weight:

[0037]

[0038]

[0039] The preparation method of the aramid fiber reinforced polypropylene micro-foaming composite material is as follows:

[0040] (1) Submerge 10 parts by weight of aramid fibers in 500mL of water, then seal and ultrasonically hydrolyze at 60°C for 6h, filter, and vacuum-dry the filtered product at 40°C for 24h to obtain hydrolyzed aramid fibers;

[0041](2) Add the hydrolyzed aramid fibers prepared in step (1), 15 parts by weight of toluene diisocyanate, and 0.075 parts by weight of dibutyltin dilaurate into 200 mL of toluene solution, and then heat and reflux at 90 ° C in a nitrogen atmosphere 4h, then naturally cooled to room temperature, and then centrifuged and washed with a high-speed centrifuge, and the centrifuged product was vacuum-dried at 60°C for 24h to obtain modified aramid fiber 1;

[0042] (3) Modifi...

Embodiment 2

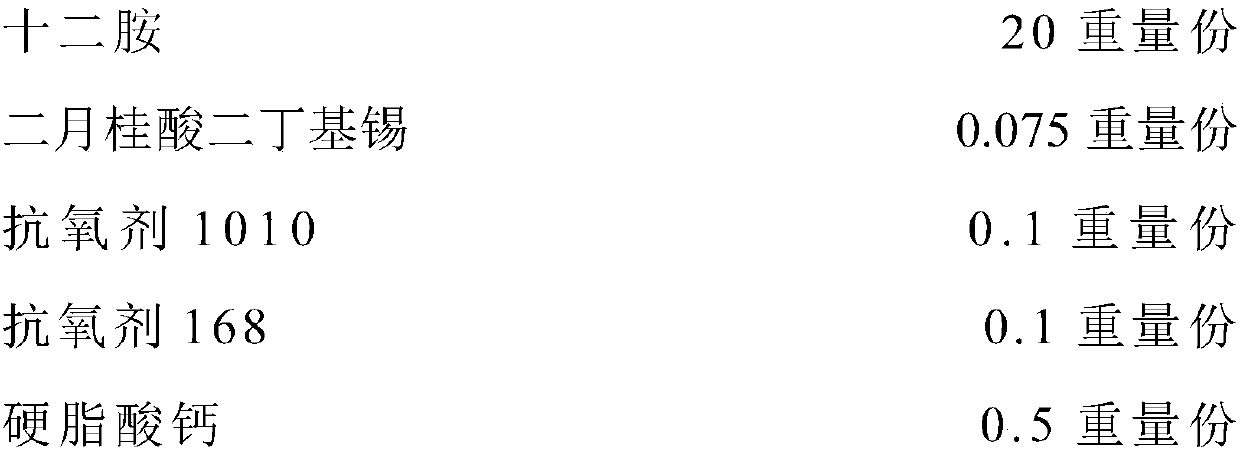

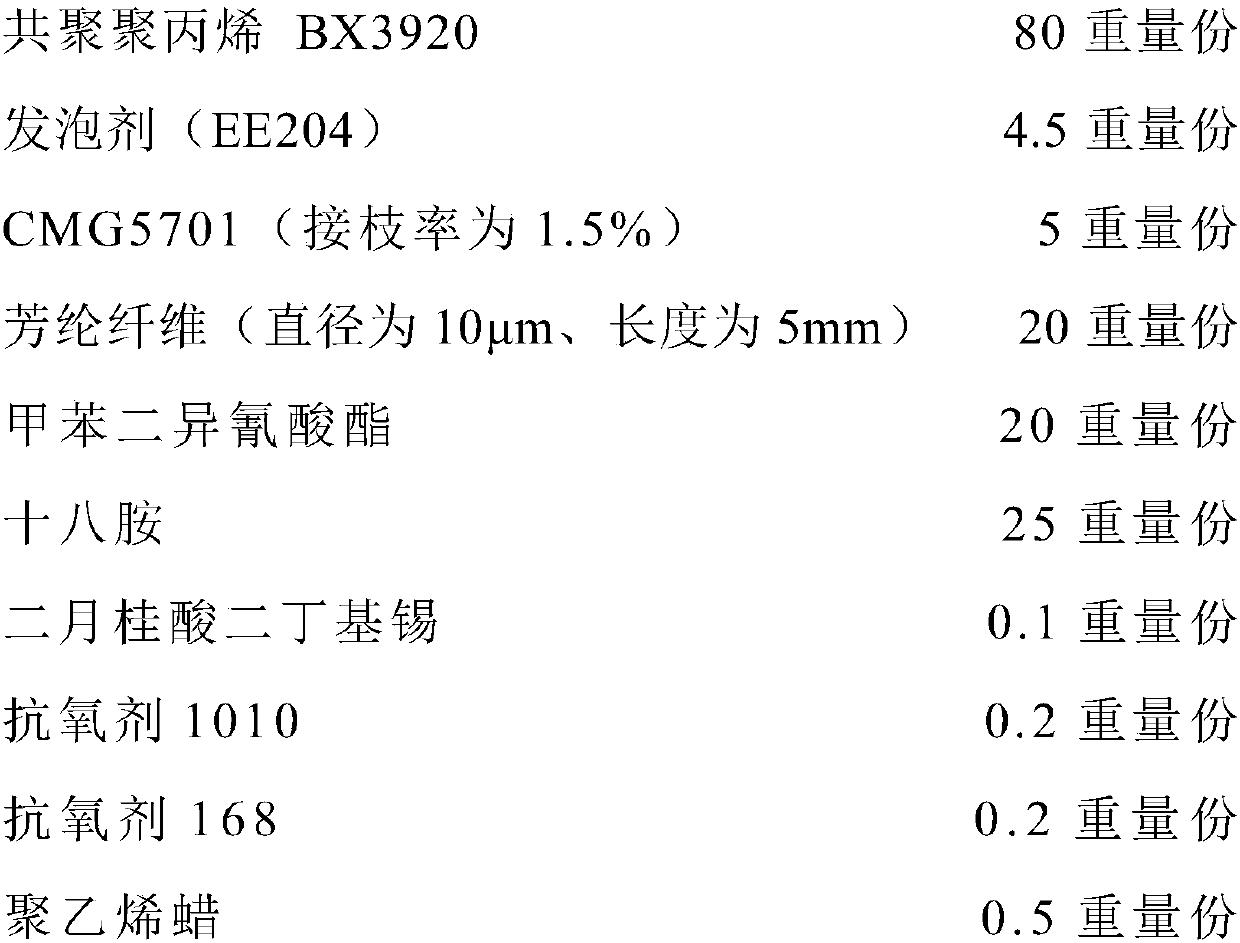

[0046] A kind of aramid fiber reinforced polypropylene micro-foaming composite material is made of the following substances by weight:

[0047]

[0048] The preparation method of the aramid fiber reinforced polypropylene micro-foaming composite material is as follows:

[0049] (1) Submerge 15 parts by weight of aramid fibers in 500 mL of water, then seal and ultrasonically hydrolyze at 80°C for 8 hours, filter, and vacuum-dry the filtered product at 50°C for 36 hours to obtain hydrolyzed aramid fibers;

[0050] (2) Add the hydrolyzed aramid fiber prepared in step (1), 20 parts by weight of toluene diisocyanate, and 0.1 part by weight of dibutyltin dilaurate to 200 mL of toluene solution, and then heat and reflux at 80 ° C in a nitrogen atmosphere 6h, then naturally cooled to room temperature, and then centrifuged and washed with a high-speed centrifuge, and the centrifuged product was vacuum-dried at 50°C for 36 hours to obtain modified aramid fiber 1;

[0051] (3) Modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com