Metal tubular material surface wiping equipment

A tubular and metal technology, applied in the field of metal tubular material surface wiping equipment, can solve the problems of time-consuming and labor-intensive, unable to clean the material, and achieve the effect of quickly wiping the material and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

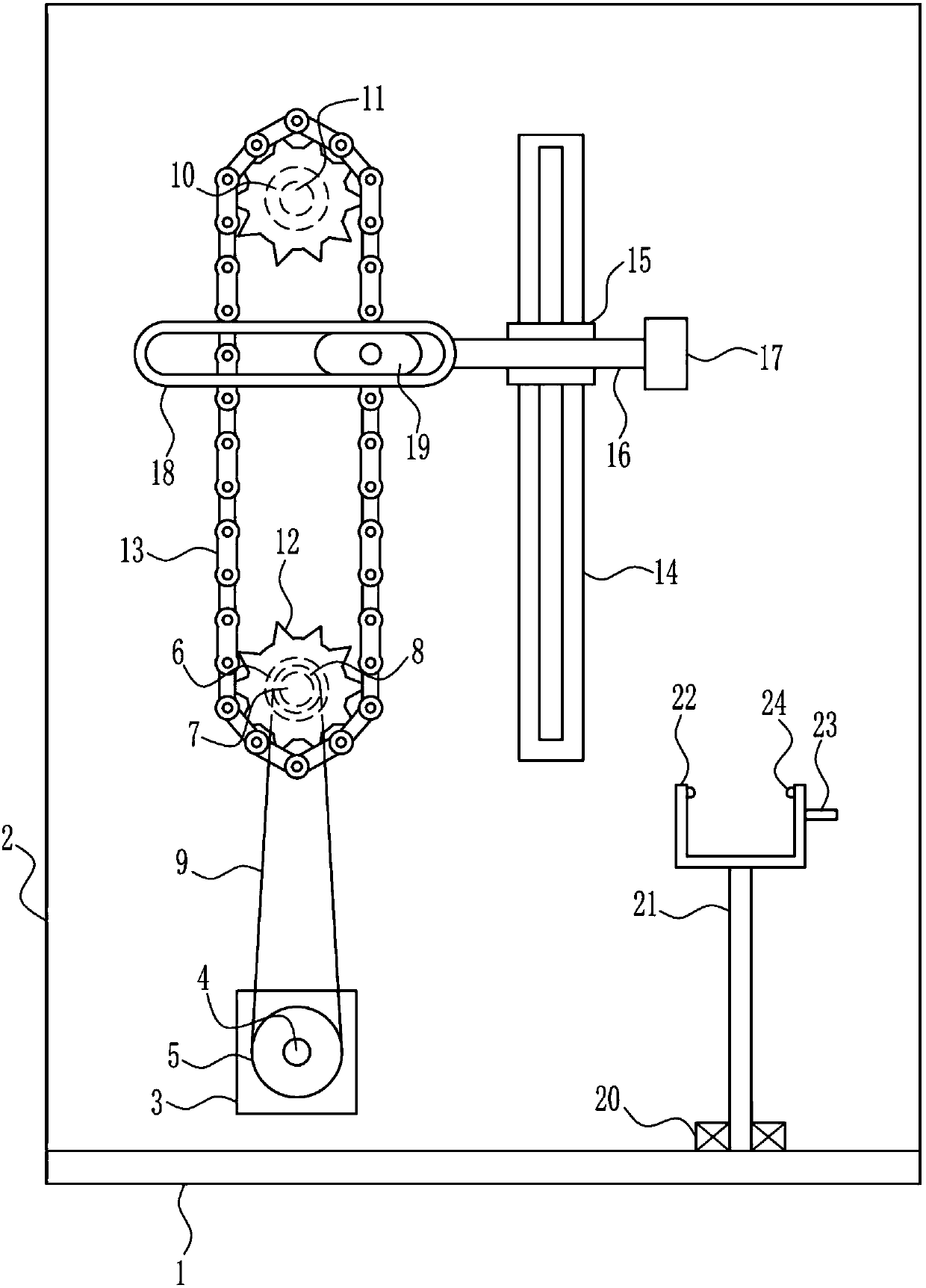

Embodiment 1

[0020] A device for wiping the surface of metal tubular materials, such as Figure 1-2 As shown, it includes a bottom plate 1, a mounting plate 2, a motor 3, a first rotating shaft 4, a large pulley 5, a first bearing seat 6, a second rotating shaft 7, a small pulley 8, a flat belt 9, a second bearing seat 10, the first Three rotating shafts 11, first gear 12, chain 13, slide rail 14, sliding block 15, connecting rod 16, friction block 17, moving frame 18, moving block 19, third bearing seat 20, fourth rotating shaft 21, frame body 22 , rotating rod 23 and rubber block 24, base plate 1 rear side is provided with mounting plate 2, and mounting plate 2 front side lower left parts are installed with motor 3, is connected with the first rotating shaft 4 on the output shaft of motor 3 front side, the first rotating shaft 4 The middle part is equipped with a large belt pulley 5, and the left part of the lower front side of the mounting plate 2 is provided with a first bearing seat 6...

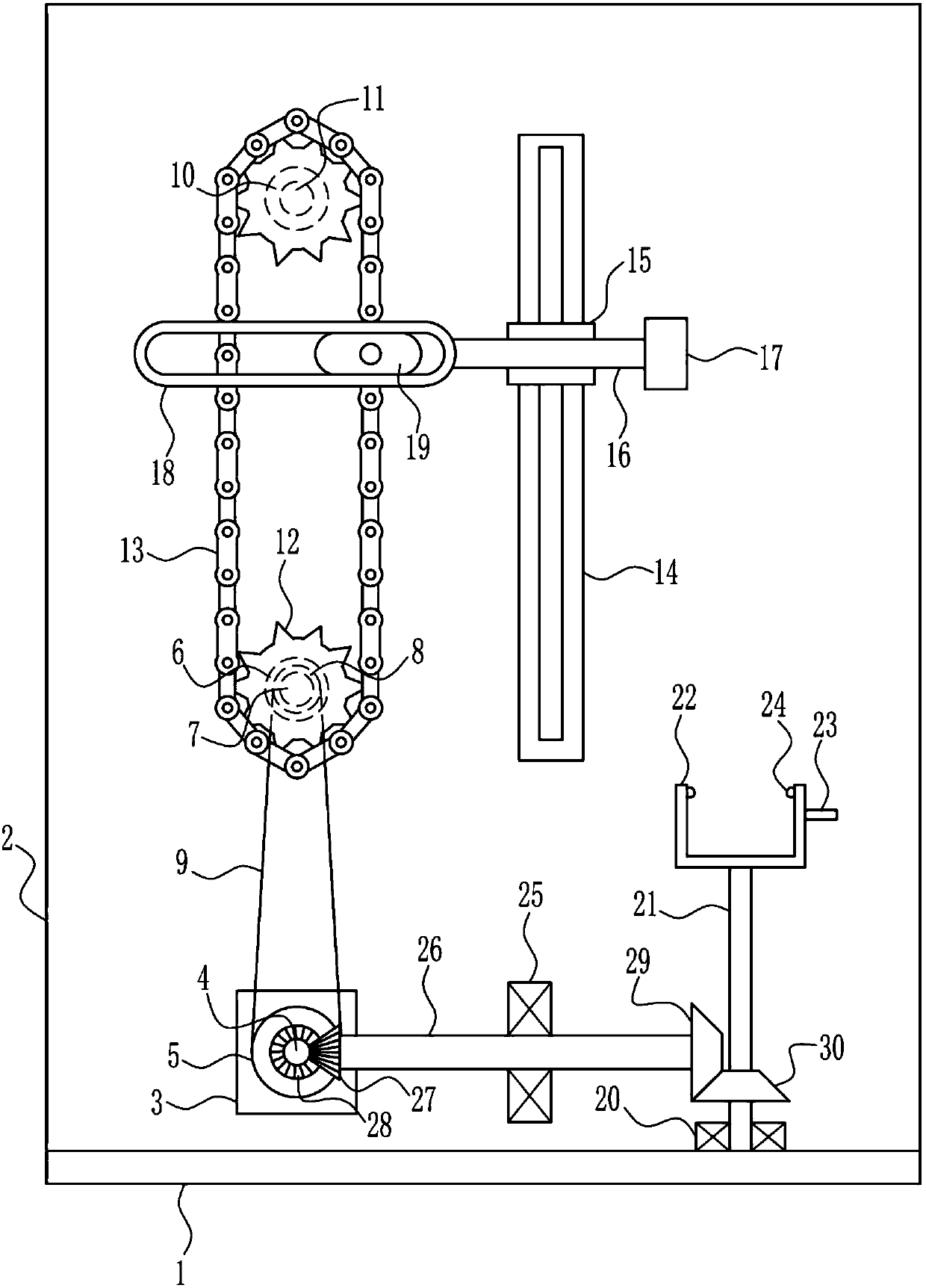

Embodiment 2

[0022] A device for wiping the surface of metal tubular materials, such as Figure 1-2 As shown, it includes a bottom plate 1, a mounting plate 2, a motor 3, a first rotating shaft 4, a large pulley 5, a first bearing seat 6, a second rotating shaft 7, a small pulley 8, a flat belt 9, a second bearing seat 10, the first Three rotating shafts 11, first gear 12, chain 13, slide rail 14, sliding block 15, connecting rod 16, friction block 17, moving frame 18, moving block 19, third bearing seat 20, fourth rotating shaft 21, frame body 22 , rotating rod 23 and rubber block 24, base plate 1 rear side is provided with mounting plate 2, and mounting plate 2 front side lower left parts are installed with motor 3, is connected with the first rotating shaft 4 on the output shaft of motor 3 front side, the first rotating shaft 4 The middle part is equipped with a large belt pulley 5, and the left part of the lower front side of the mounting plate 2 is provided with a first bearing seat 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com