Protection cover device for liquid static spraying gun

A technology of electrostatic spray gun and protective cover, applied in the direction of spraying device, etc., can solve problems such as unfavorable spraying work, large dust accumulated in the nozzle, blockage at the nozzle, etc., to achieve the effect of convenient assembly, disassembly and replacement, avoiding accumulation and blockage, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

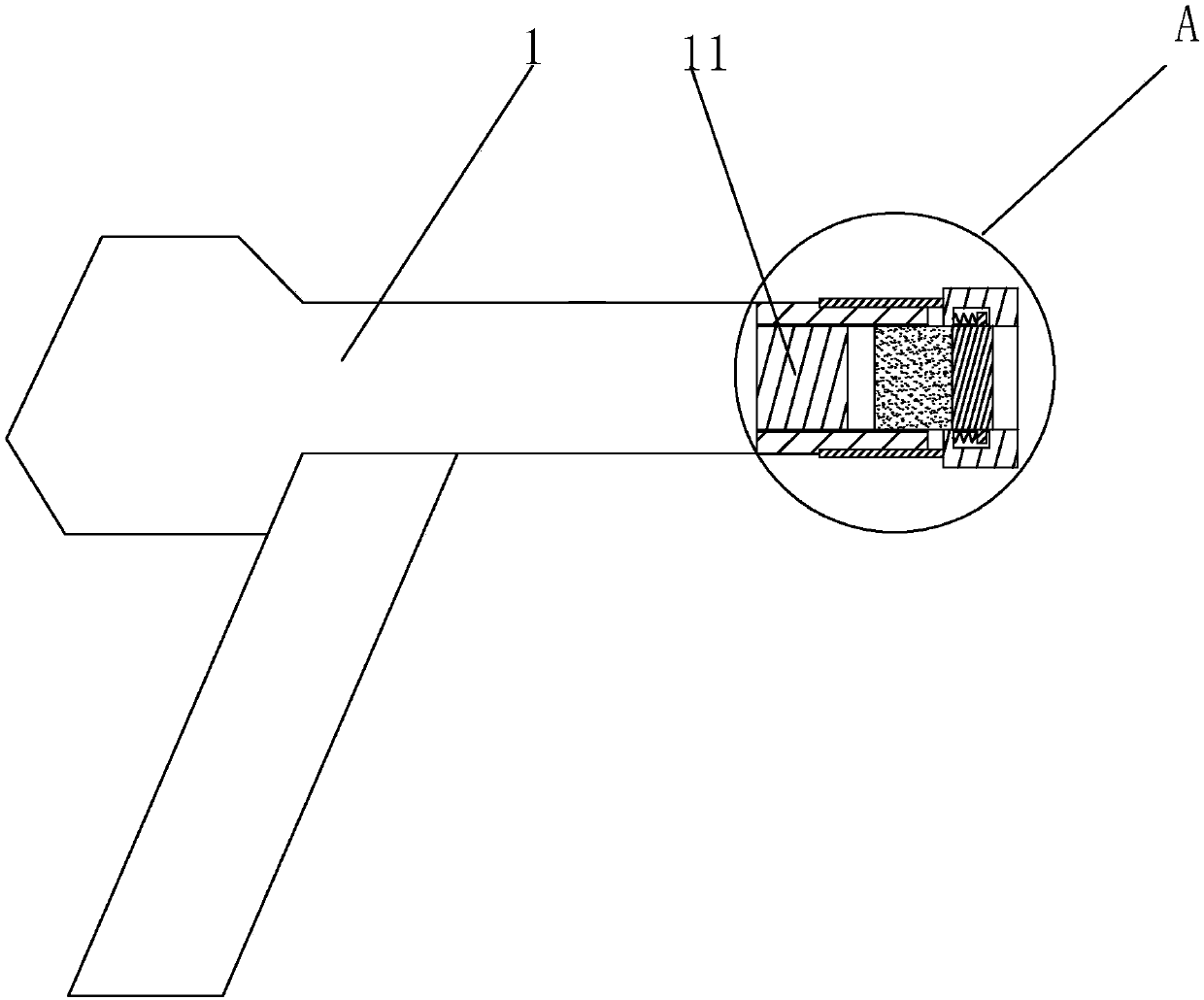

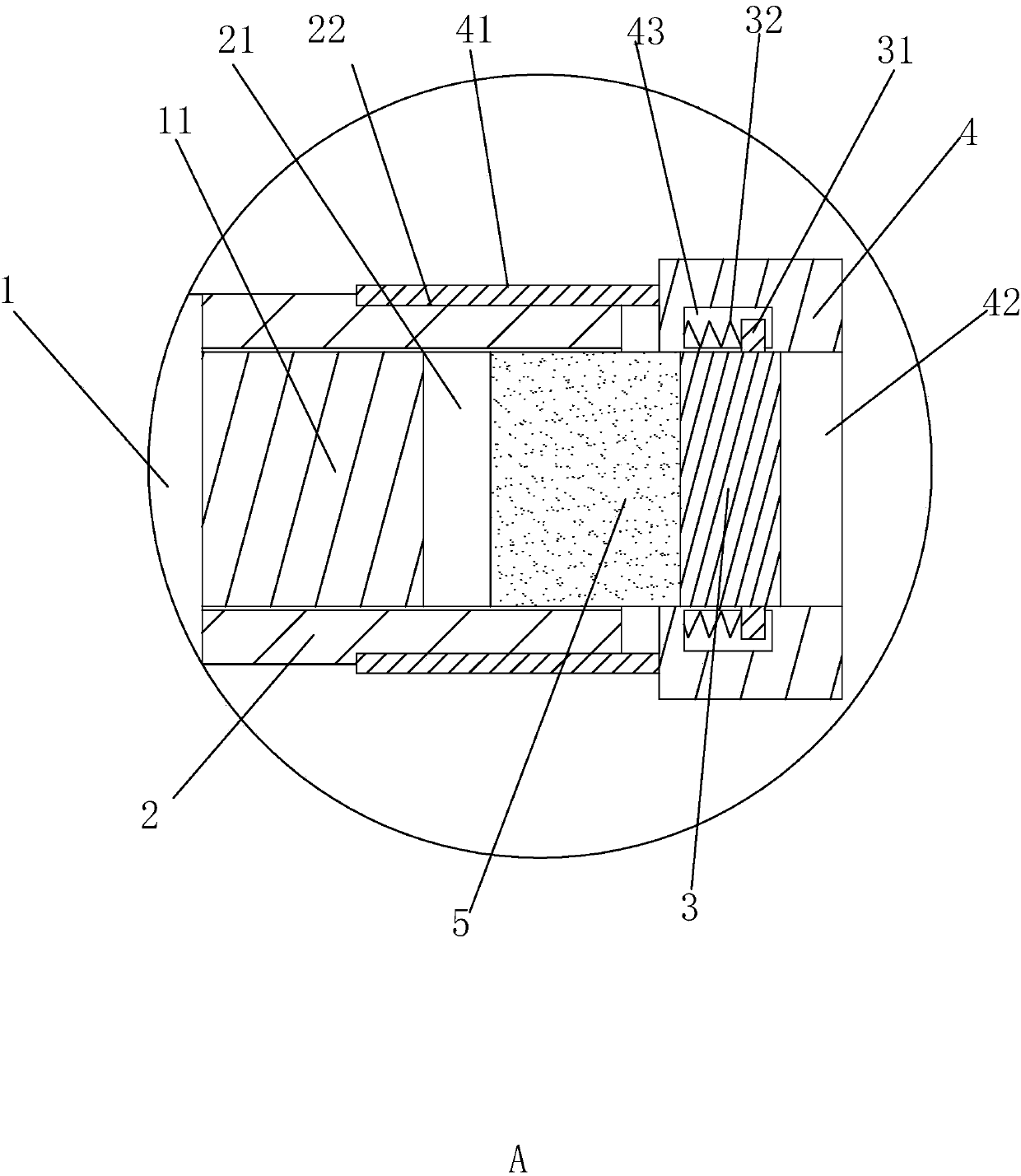

[0026] Embodiment 1: a kind of protective cover device for liquid electrostatic spray gun, such as figure 1 with 2 As shown, the liquid electrostatic spray gun mainly includes a gun body 1 and a nozzle 11, and the protective cover device includes a bumper sleeve 2 threaded on the nozzle 11. The protective cover is cylindrical, and the bumper sleeve 2 is provided with a nozzle 11 for insertion. One end of the anti-collision sleeve 2 is provided with a plug 3 that closes the anti-collision sleeve 2, and one end of the plug 3 is provided with a connecting block 4, and the circumferential array on the connecting block 4 is provided with a plurality of connecting clips 41, Specifically 3-5, the outer peripheral surface of the anti-collision sleeve 2 is provided with a plurality of limit slideway grooves 22 for the sliding and embedding of the connecting clip 41, and the connecting block 4 is provided with a passage for the plug 3 to penetrate. Hole 42.

[0027] At the same time, ...

specific Embodiment approach

[0028] Specific embodiments: under normal conditions, the anti-collision sleeve 2 can be threadedly installed on the nozzle 11, and under the action of the threaded hole 21, the nozzle 11 can communicate with the outside easily, and the spraying work to the workpiece can be realized smoothly.

[0029] When the liquid electrostatic spray gun is in an idle state, the plug 3 can be installed on the anti-collision sleeve 2, that is, the connecting clips 41 only need to be embedded in the corresponding limit slideway grooves 22 respectively, and then the connecting clips are slid 41, so that it is completely embedded in the limit slideway groove 22, the installation of the plug 3 can be realized. At this time, the plug 3 is inserted into the anti-collision sleeve 2, and the plug 3 effectively realizes the closure of the anti-collision sleeve 2. That is, the sealing of the nozzle 11 is realized, which effectively prevents the nozzle 11 from being blocked by a large amount of dust whe...

Embodiment 2

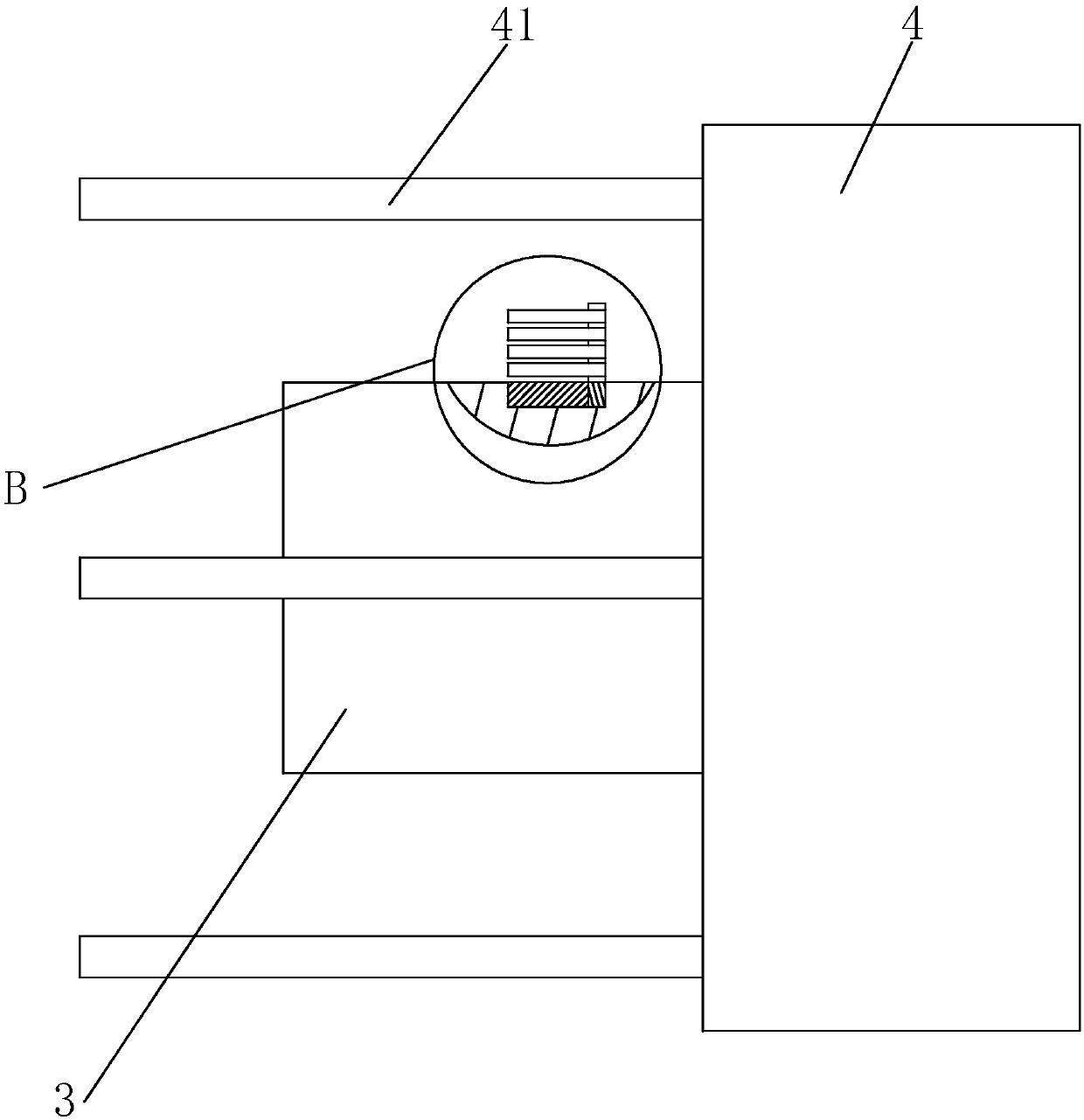

[0032] Embodiment 2: a protective cover device for a liquid electrostatic spray gun, the difference from Embodiment 1 is that, as image 3 with 4 As shown, the above-mentioned water-absorbent cotton cloth layer 5 is wound on the outer circumferential surface of the plug 3, and a fixing mechanism 6 acting on the water-absorbent cotton cloth layer 5 is provided on the connecting block 4. 3, close to the positioning magnet 61 of the connecting block 4, the upper surface of the positioning magnet 61 is flush with the outer circumferential surface of the plug 3, and a connecting rod 62 is fixed on the positioning magnet 61, and the connecting rod 62 rotates in an array A plurality of compression magnets 63 are provided, and the distance between every two compression magnets 63 is 1-3mm.

[0033] Specific embodiments: The rapid assembly and disassembly of the water-absorbent cotton cloth layer 5 can be conveniently realized by winding, that is, the water-absorbent cotton cloth laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com