Ball mill packing and sealing device

A packing sealing and sealing device technology, applied in the field of ball mills, can solve the problems of increasing the gap between the end cover hole and the rotating shaft, unavoidable oil leakage, and ineffective throttle grooves, so as to reduce wear, save costs, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

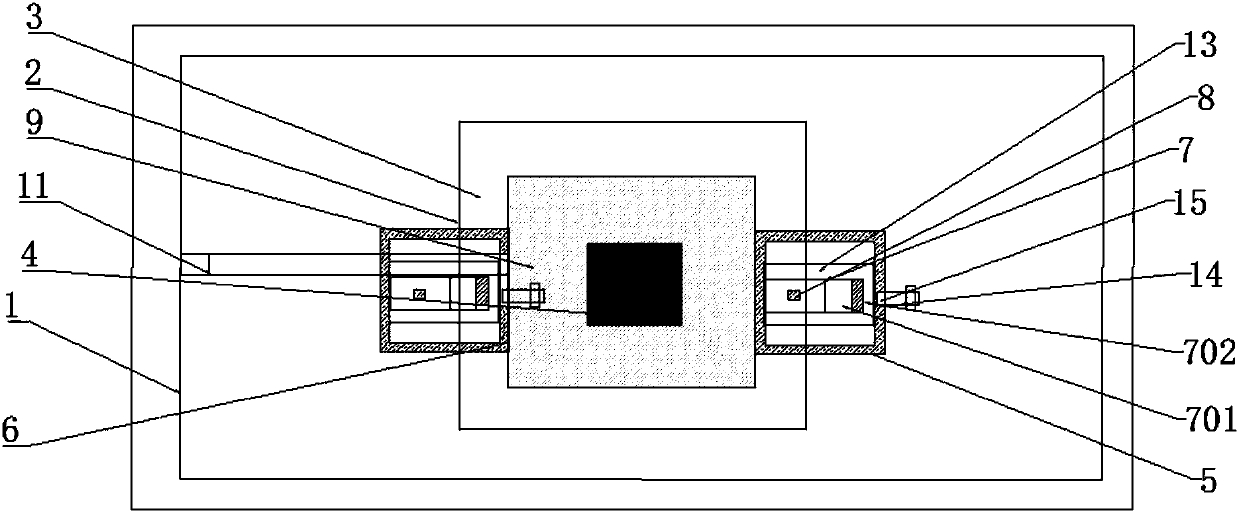

[0025] Such as figure 1 and figure 2 As shown, the present invention provides a packing sealing device for a ball mill, including a casing 1, the casing 1 is a cuboid box structure with an opening facing upwards, and a packing device 2 is installed at an upper position inside the casing 1, and the packing The device 2 includes a feed hopper 3 and a feed barrel 4. The feed hopper 3 is located at the opening of the cabinet 1 and has a trapezoidal cross section. At the feed port; the inside of the cabinet 1 is also equipped with a sealing device 5, the sealing device 5 is sleeved on the outer surface of the feeding cylinder 4, the sealing device 5 includes a sealing seat 6, the overall appearance of the sealing seat 6 It is a cuboid, and the center of the sealing seat 6 is dug with a through hole. The inner diameter of the through hole of the sealing seat 6 matches the outer diameter of the end of the feeding barrel 4. The sealing seat 6 is sleeved on the outer surface of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com