A method for measuring the release of heavy metal elements in snus

A measurement method and technology of snus, which is applied in the field of chemical analysis and detection, can solve the problems of unscientific quality and safety evaluation of snus products, low release amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Measurement method

[0058] 1.1 Sample pretreatment

[0059] Accurately weigh the snus sample and place it in the solid-phase extraction empty column, accurate to 0.1mg, then put the solid-phase extraction column into the designated position of SPE, after cleaning the pipeline, slowly add artificial saliva to the sample as eluent Solid-phase extraction, collecting the liquid after washing. Wherein, the solid-liquid ratio of the added weight of the snus sample to the added volume of the artificial saliva is 2-12:20, g / ml.

[0060] Set the conditions of solid phase extraction, specifically: sample loading time: 15-25min; number of channels: 3-5 channels; pipeline cleaning solution: ultrapure water; volume of pipeline cleaning solution: 5-15mL; The extraction rate: 5-15mL / min; the cleaning rate of the pipeline cleaning solution: 5-15mL / min; the cleaning times of the pipeline cleaning solution: 2-4 cycles; the eluent: artificial saliva; the volume of the eluent : 1-3m...

Embodiment 2

[0073] 1. Measurement method

[0074] 1.1 Sample pretreatment

[0075] Accurately weigh the snus sample and place it in the solid-phase extraction empty column, accurate to 0.1mg, then put the solid-phase extraction column into the designated position of SPE, after cleaning the pipeline, slowly add artificial saliva to the sample as eluent Solid-phase extraction, collecting the liquid after washing. Wherein, the solid-liquid ratio of the added weight of the snus sample to the added volume of the artificial saliva is 4-10:20, g / ml.

[0076] Set the conditions of solid phase extraction, specifically: sample loading time: 20min; number of channels: 4 channels; pipeline cleaning solution: ultrapure water; volume of pipeline cleaning solution: 10mL; extraction rate of pipeline cleaning solution: 10mL / min; cleaning rate of pipeline cleaning solution: 10mL / min; cleaning times of pipeline cleaning solution: 2 cycles; eluent: artificial saliva; volume of eluent: 2mL; extraction rate...

Embodiment 3

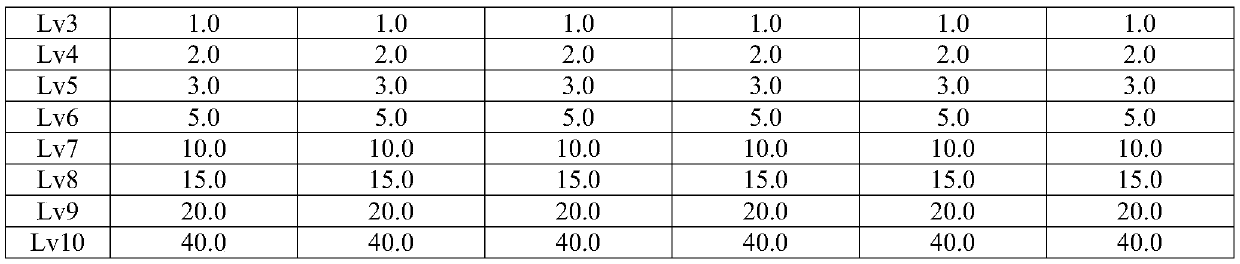

[0092] 1. Standard working curve, detection limit and quantification limit

[0093] According to 1.2 in Example 2, a series of mixed element standard solutions of chromium, nickel, arsenic, selenium, cadmium and lead with different concentrations were prepared, and the specific concentration ranges are shown in Table 2. Simultaneously, prepare germanium by 1.2 in embodiment 2 72 ,indium 115 ,bismuth 209 Mixed element internal standard solution.

[0094] A series of standard solutions with different concentrations prepared above and the internal standard solution are respectively according to the provisions of 1.3 in Example 2, and ICP-MS detection is carried out synchronously, and the mass-to-charge ratio intensity ratio of the corresponding element / corresponding internal standard element is the ordinate (Y axis), the mass concentration ratio of its corresponding corresponding element / corresponding internal standard element is abscissa (X axis), carries out regression analy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com