Automatic assembling machine for vehicle-mounted antenna

An automatic assembly machine, vehicle-mounted antenna technology, applied in conveyor objects, transportation and packaging, metal processing, etc., can solve the problems of affecting product stability, inaccurate assembly position, and high waste generation rate, to reduce defective products, automate High degree of energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

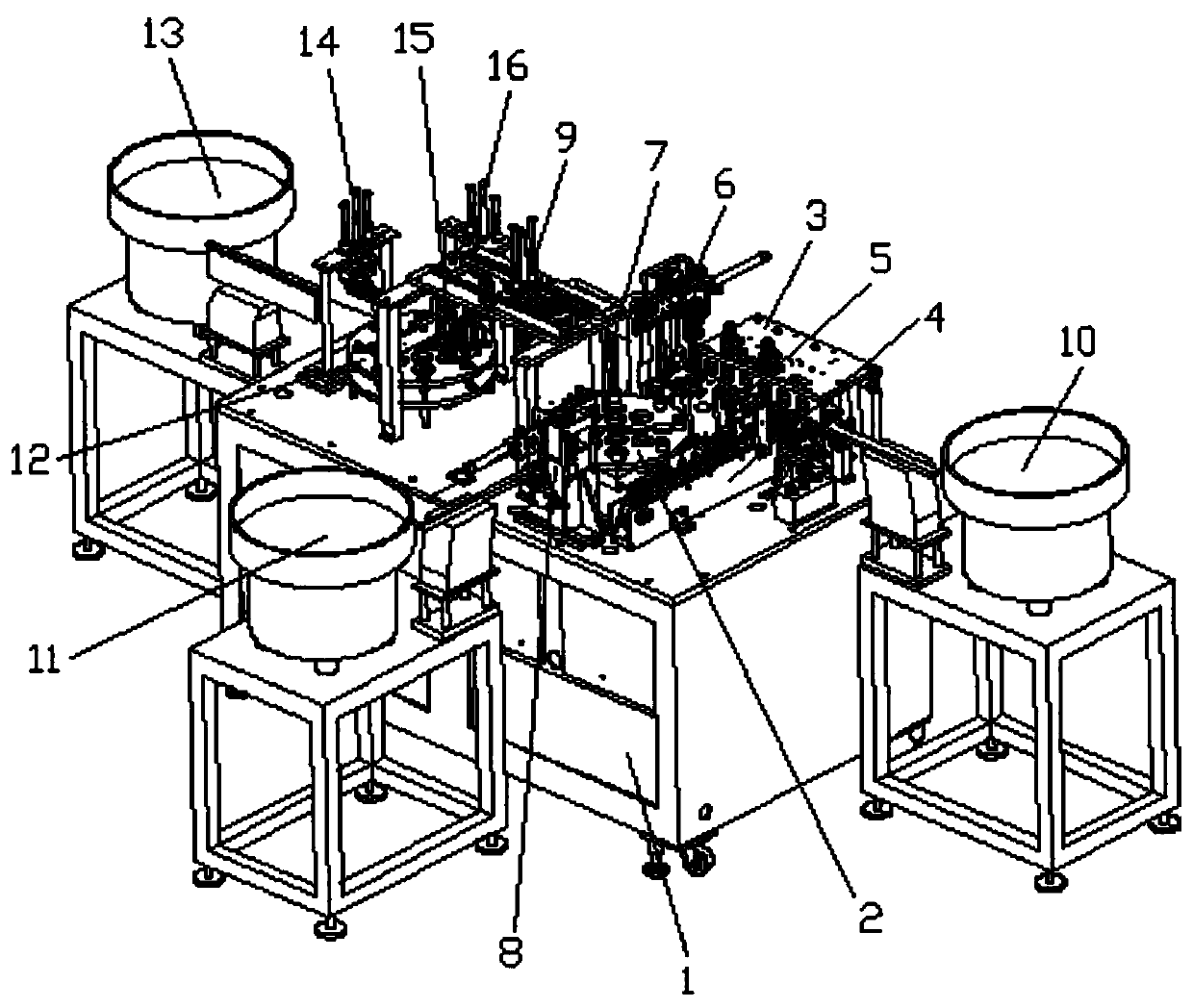

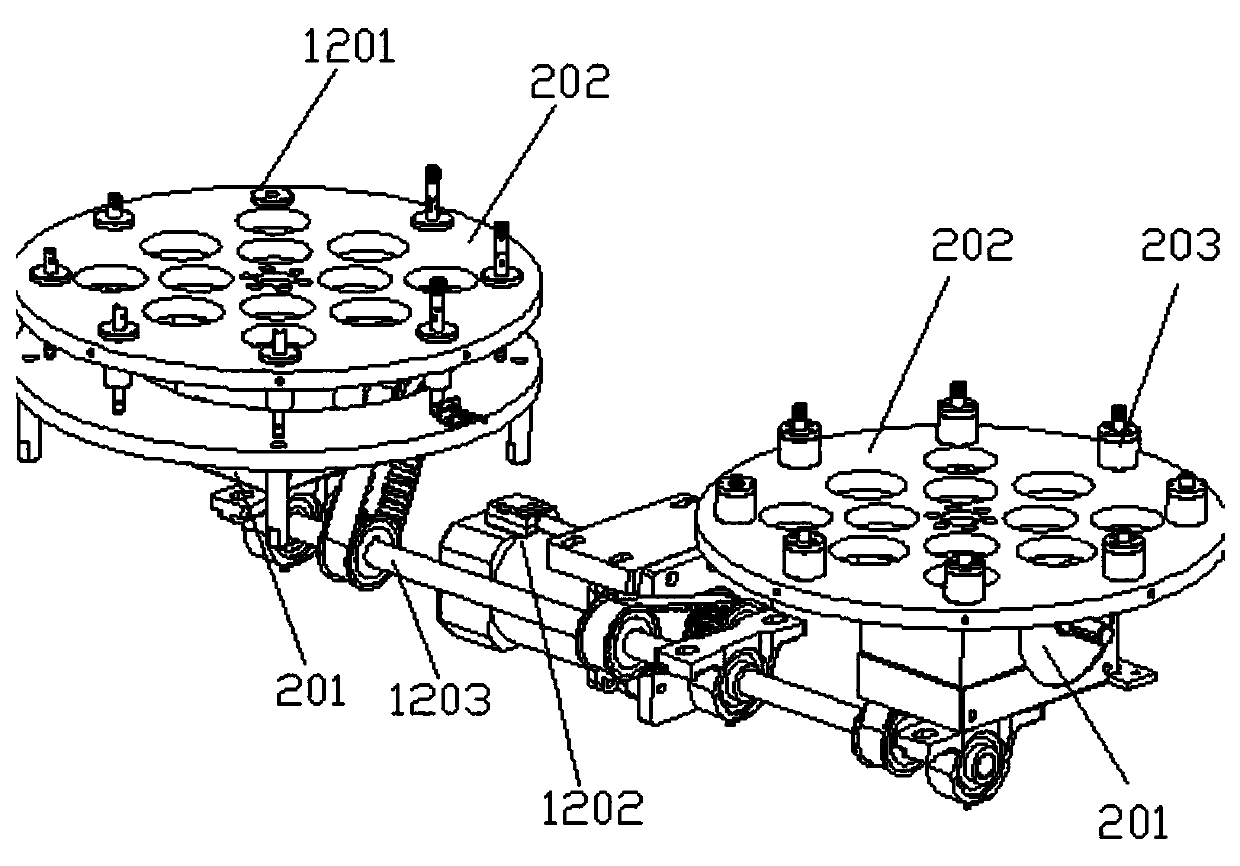

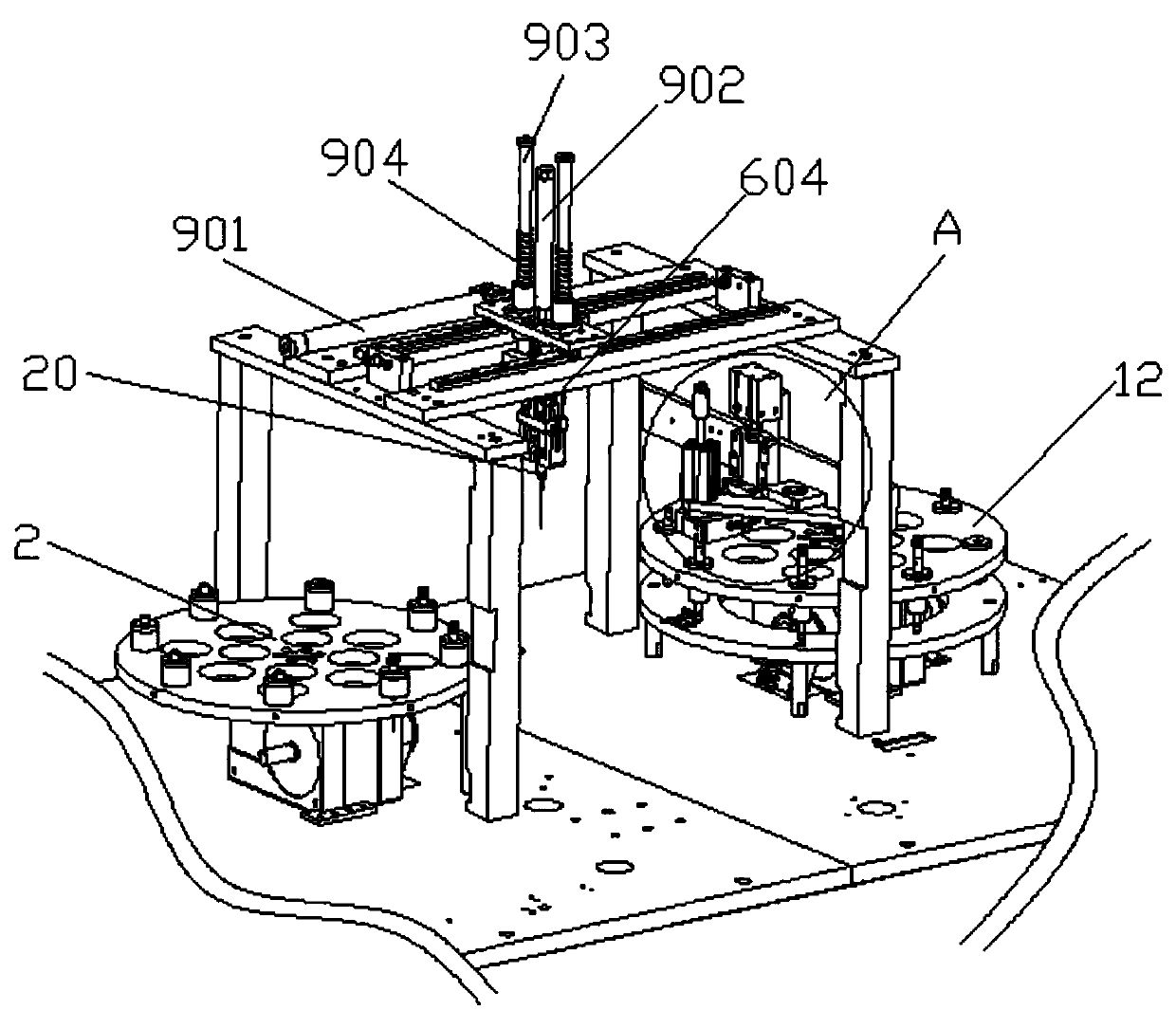

[0041] Such as Figure 1-Figure 13 As shown, the structure of the present invention is: an automatic assembly machine for vehicle-mounted antennas, which includes a frame and a power distribution control box arranged in the frame, and the upper end of the frame is correspondingly provided with a base rotating device and a shield rotating device , the shield rotating device is sequentially provided with shield feeding device, transfer device and unloading device along the direction of rotation, the finished product assembly device is installed under the transfer device, and the finished product assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com