Ceramic substrate manufacturing method and ceramic substrate manufactured thereby

一种陶瓷基板、制造方法的技术,应用在印刷电路制造、陶瓷层状产品、化学仪器和方法等方向,能够解决生产率降低、花费长时间、失灵等问题,达到简化制造工艺、简化蚀刻工艺、减少缺陷部分的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. Duplicate descriptions and descriptions of known functions and configurations considered to obscure the gist of the present invention will be omitted below. The embodiments of the present invention are intended to fully describe the present invention to those skilled in the art to which the present invention pertains. Therefore, the shapes, dimensions, etc. of components in the drawings may be exaggerated to clarify the description.

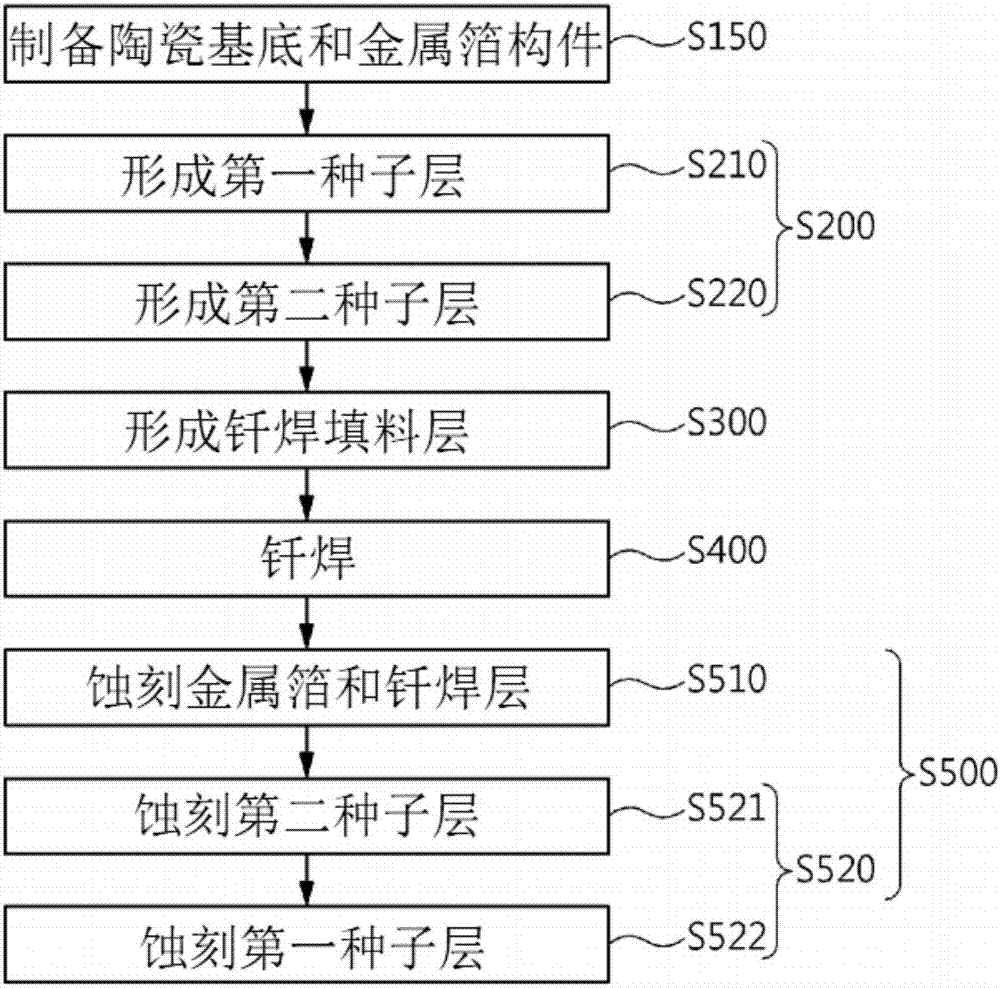

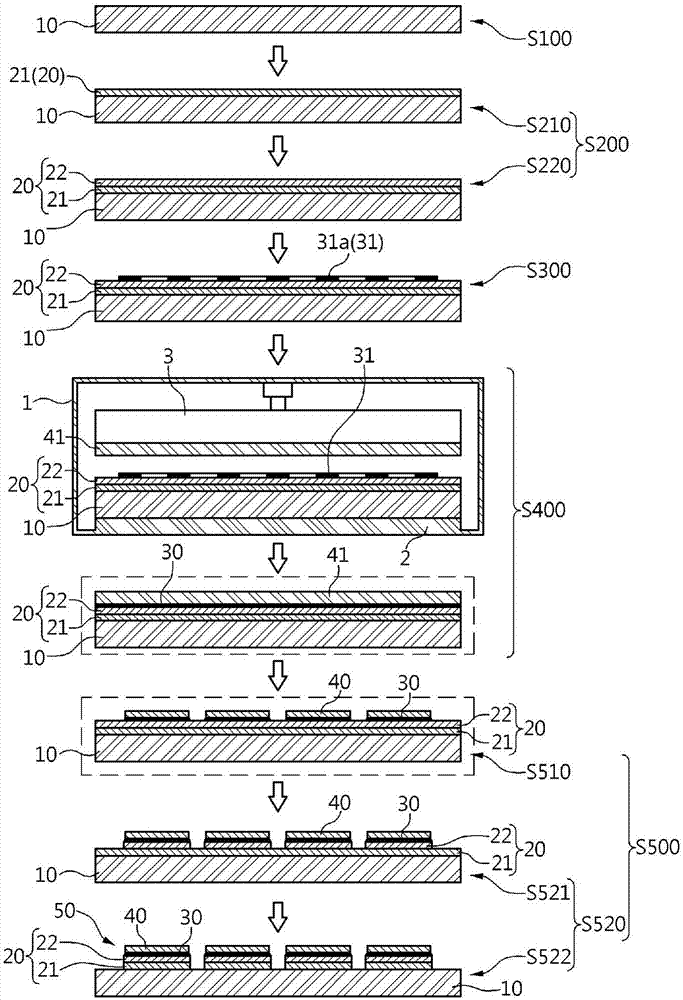

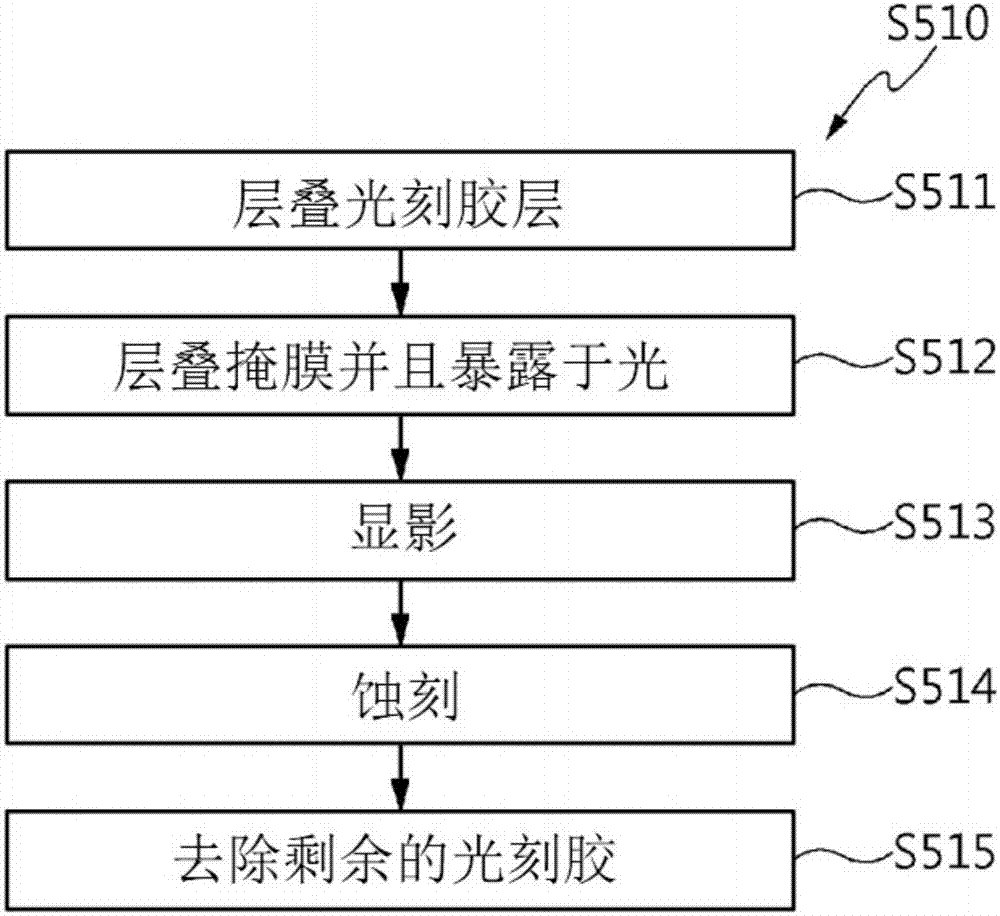

[0057] refer to figure 1 and 2 , The manufacturing method of the ceramic substrate according to one embodiment of the present invention comprises: prepare ceramic substrate 10 and metal foil 40 (S100), form seed layer 20 (S200) on ceramic substrate 10, form brazing filler on seed layer 20 layer 31 (S300), and the metal foil 40 is laminated on the brazing filler layer 31 and brazed (S400).

[0058] Preferably, preparing the cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com