Vector control system for high-voltage frequency converter and strategy method thereof

A high-voltage frequency converter and vector control technology, applied in the field of vector control, can solve problems such as the inability to stably establish magnetic field, voltage, and current oscillations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

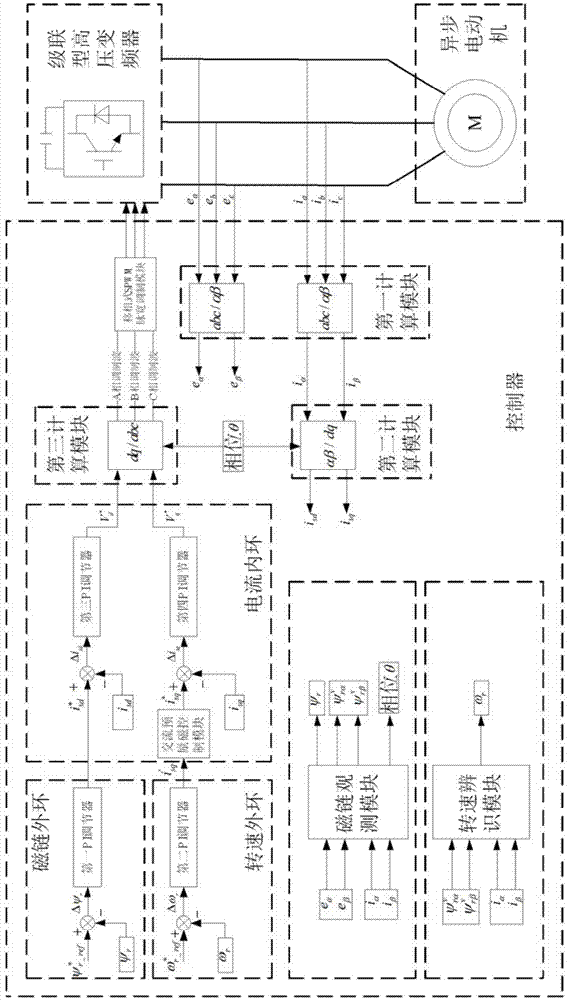

[0028] Such as figure 1 As shown, a vector control system for a high-voltage frequency converter includes a high-voltage frequency converter, an asynchronous motor and a controller, the high-voltage frequency converter is electrically connected to the asynchronous motor, and the signal input terminals of the controller are respectively connected to the high-voltage frequency The signal output end of the controller and the signal input end of the asynchronous motor are electrically connected to collect the current or voltage signal, and the signal output end of the controller is electrically connected to the signal output end of the high-voltage frequency converter to perform the current or voltage signal Pre-excitation control, PI regulation, and voltage feedforward are used to output pulse width modulation signals for the high-voltage frequency converter to control the starting of the asynchronous motor. In this embodiment, the high-voltage frequency converter is a cascaded hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com