Electrode plate production equipment

A production equipment and pole piece technology, applied in the field of pole piece production equipment, can solve the problems of low pass rate, position deviation, low battery production efficiency, etc., and achieve the effect of improving production efficiency, improving process speed and improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

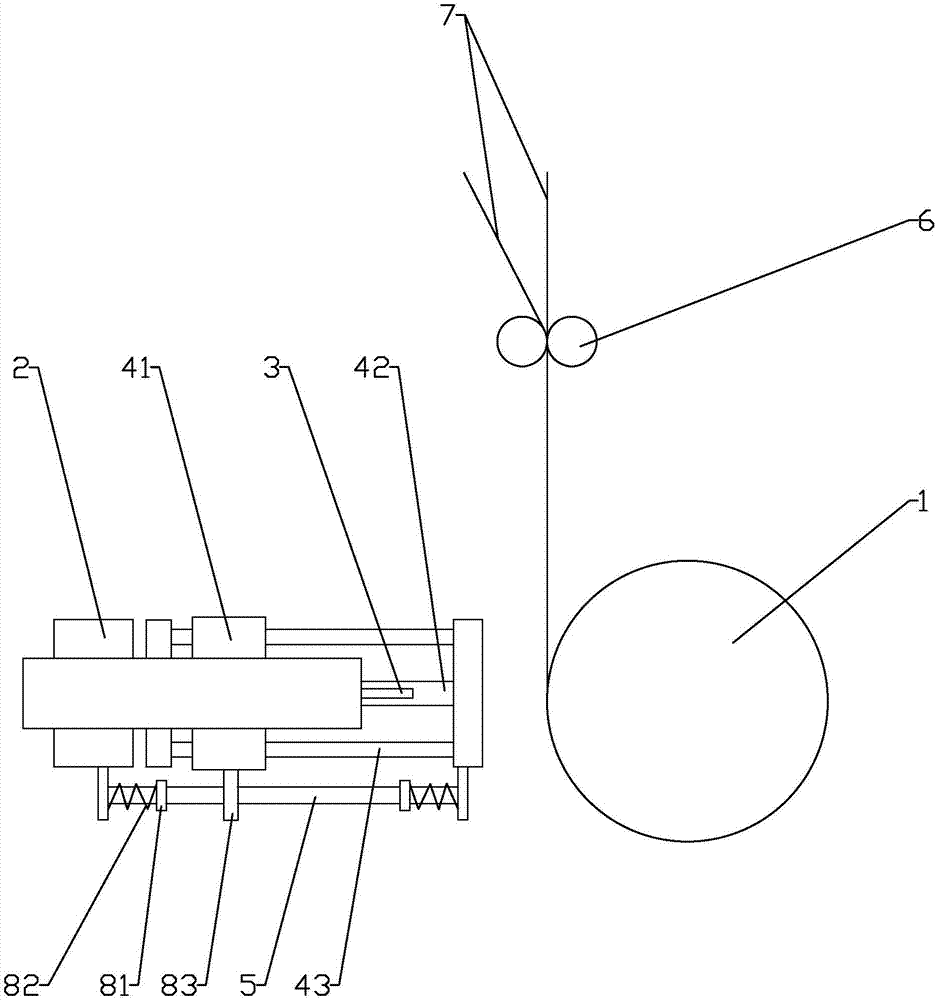

[0014] like figure 1 As shown, a pole piece production equipment includes a winding machine, and the winding machine includes a mandrel 1 for winding a positive pole piece, a separator 7 and a negative pole piece, and also includes a mounting bracket 2, a driving mechanism and a heating welding The diaphragm 7 is bonded to the welding part 3 on the surface of the mandrel 1 in a manner, and the driving mechanism is installed on the mounting bracket 2, and the driving mechanism includes a slider 41, a screw 42, a motor for driving the screw 42 to rotate, two and The screw rod 42 is parallel to and respectively arranged on the guide rods 43 on both sides of the screw rod 42 , the slider 41 is threadedly connected with the screw rod 42 and slidably connected with the two guide rods 43 , and the welding part 3 is installed on the slider 41 . The motor drives the screw rod 42 to rotate, so that the slider 41 moves, and the welding part 3 approaches or moves away from the mandrel 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com