Film coating method capable of enabling lens to achieve wear resistance, corrosion resistance and reflection resistance

A lens sheet, anti-corrosion technology, applied in the field of lenses, can solve the problems that affect the user's observation of things, scratch or break hard objects, increase the cost of use, etc., to improve the anti-blue light effect, dense film layer, delay The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

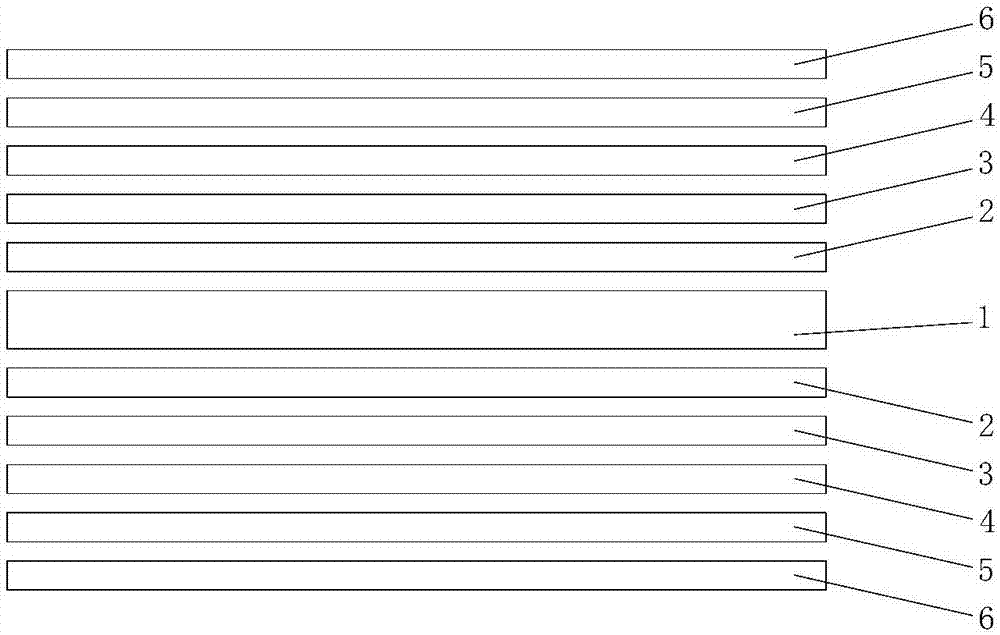

[0043] Such as figure 1 As shown, in the anti-wear, anti-corrosion and lens-increasing lens coating method of the present invention, the lens includes a substrate 1 molded by resin or glass, and the inner and outer surfaces of the substrate 1 are symmetrical from the inside to the outside. The first film layer 2, the second film layer 3, the third film layer 4, the fourth film layer 5 and the fifth film layer 6 are provided in sequence; the first film layer 2 is a titanium pentoxide layer with a thickness of 20 -80nm; the second film layer 3 is a silicon dioxide layer with a thickness of 60-90nm; the third film layer 4 is a metal layer with a thickness of 25-40nm; the fourth film layer 5 is an anti-corrosion film layer with a thickness of 10-50nm; the fifth film layer 6 is a high-hardness layer with a thickness of 20-40nm; when the substrate is molded by resin, the coating method specifically includes the following steps:

[0044] 1) Clean and dry the substrate;

[0045] 2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com