Solid ice-melting composition used for ice removal for power transformation equipment and preparation method of same

A technology for substation equipment and compositions, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as large cost, secondary crystallization, and hidden safety hazards, achieve rapid melting of ice and snow, reduce corrosion, The effect of preventing secondary icing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

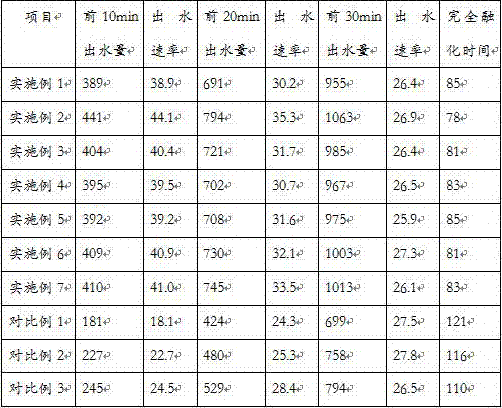

Examples

preparation example Construction

[0023] The preparation method of the solid ice-melting composition for substation equipment deicing of the present invention comprises the following steps:

[0024] Step 1, adding soda ash to sodium chloride and stirring to mix evenly to obtain powdery mixture A;

[0025] Step 2. After mixing trichloroacetic acid and other components, heat and dry at 80° C. for 20-30 minutes to obtain mixture B;

[0026] Step 3. Crushing the mixture B into the desired particle size as required, stirring and mixing the mixture A and the mixture B under dry conditions to obtain a solid ice-melting composition.

Embodiment 1

[0029] Take 63 grams of sodium chloride and 24 grams of soda ash and stir and mix evenly to obtain a powdery mixture A, then mix 10 grams of trichloroacetic acid, 1 gram of sodium benzoate and 2 grams of calcium carbonate and heat and dry at 80 ° C for 23 minutes to obtain a mixture B, and then crush the mixture B into powder and add it into the mixture A and stir to mix evenly to obtain 100 grams of ice-melting composition.

Embodiment 2

[0031] Take 60 grams of sodium chloride and 27 grams of soda ash and stir and mix evenly to obtain a powdery mixture A, then mix 13 grams of trichloroacetic acid, 1 gram of zeolite and 2 grams of calcium carbonate and heat and dry at 80°C for 20 minutes to obtain a mixture B , and then the mixture B was crushed into powder and added to the mixture A and stirred evenly to obtain 100 grams of ice-melting composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com