Multifunctional charging platform for production of aluminum alloy

A feeding platform, aluminum alloy technology, applied in the direction of magnetic separation, conveyor objects, solid separation, etc., can solve the problems of no electric transmission structure, non-adjustable feeding plate, single function, etc., to achieve the convenience of moving and fixing the feeding platform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

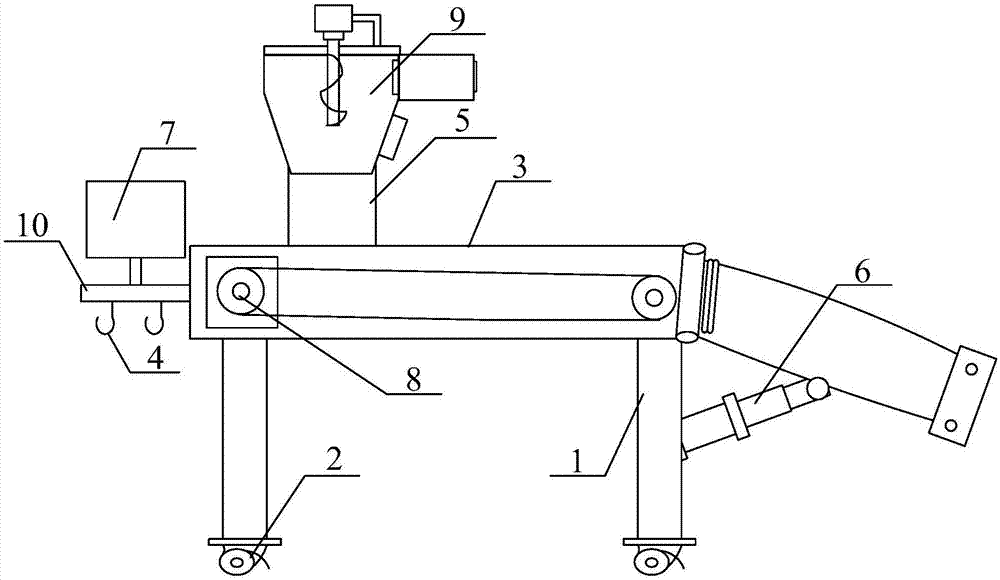

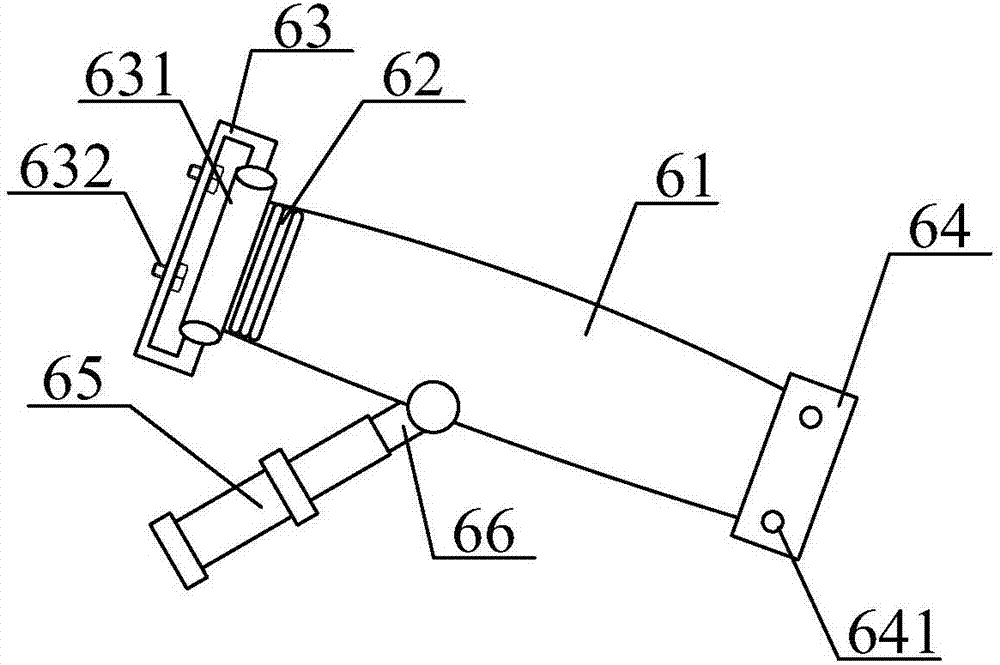

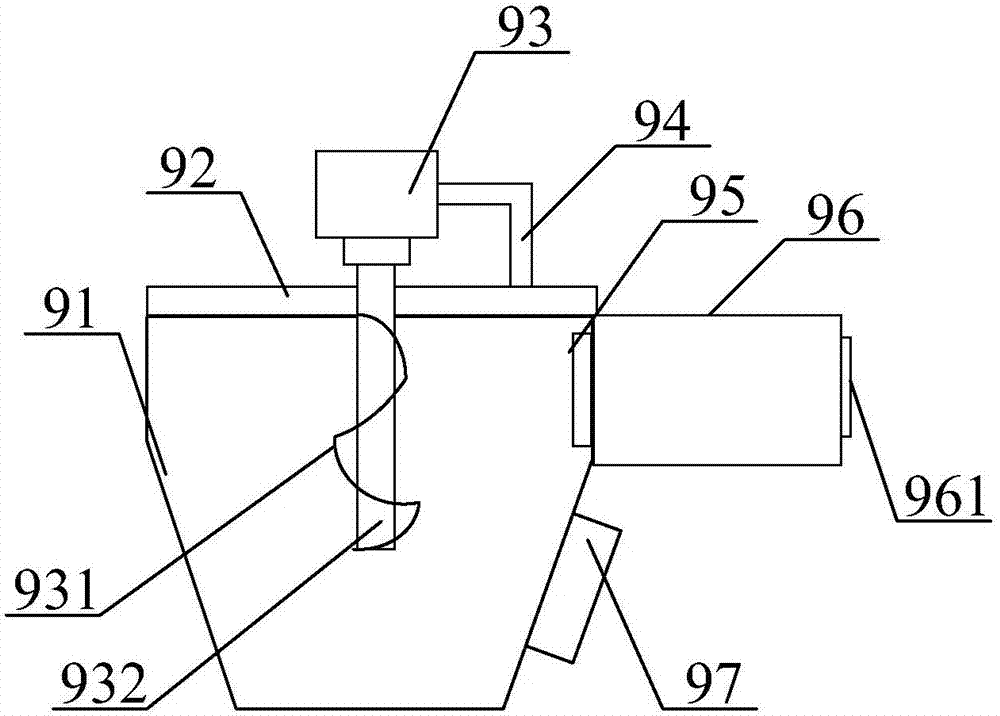

[0035] as attached figure 1 to attach Figure 5 shown

[0036] The invention provides a multifunctional feeding platform for aluminum alloy production, which includes a support column 1, a universal wheel 2, a feeding platform 3, a hook 4, a rubber cylinder 5, a feeding plate structure 6, a control plate structure 7, and a conveyor belt structure 8. The hopper structure 9 and the support plate 10, the support column 1 is bolted to the four corners of the lower surface of the feeding platform 3; the universal wheel 2 is bolted to the lower end of the support column 1; the hook 4 is welded on The lower surface of the support plate 10; the rubber cylinder 5 is bolted to the left side of the upper surface of the feeding platform 3; the feeding plate structure 6 is bolted to the right side of the feeding platform 3; the control board structure 7 Welded in the middle of the upper surface of the support plate 10; the conveyor belt structure 8 is connected to the middle of the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com