Joint structure and method of manufacturing joint structure

A technology for joining structures and manufacturing methods, applied in the directions of manufacturing tools, connecting members, welding equipment, etc., can solve problems such as cracking, increase in absorption rate, and decrease in adhesion, achieve excellent suction adhesion, and correct warpage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

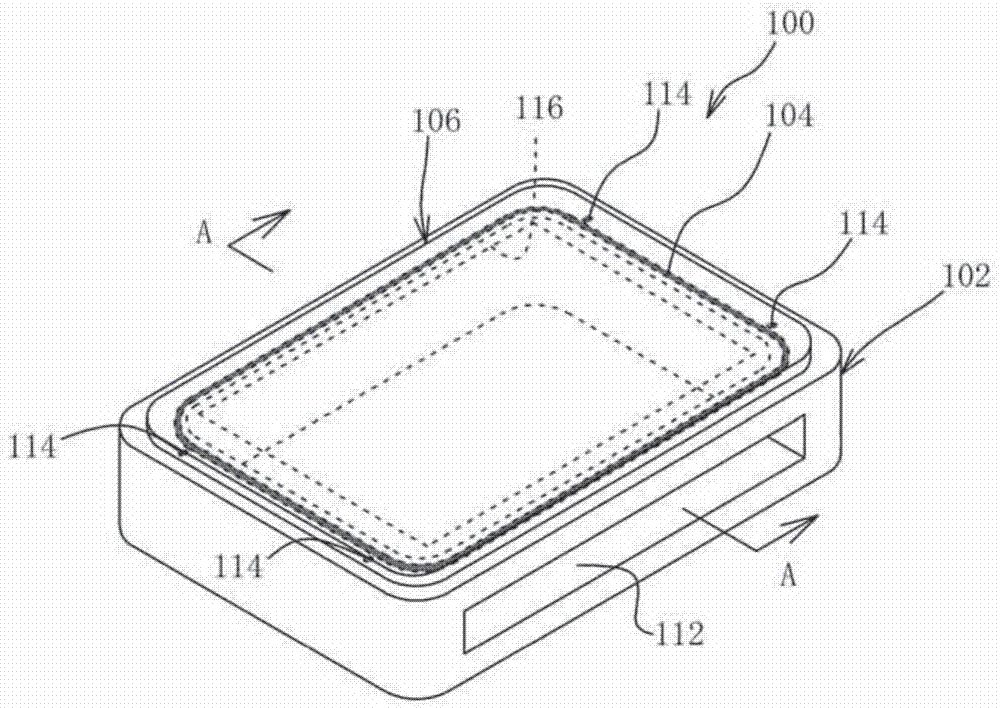

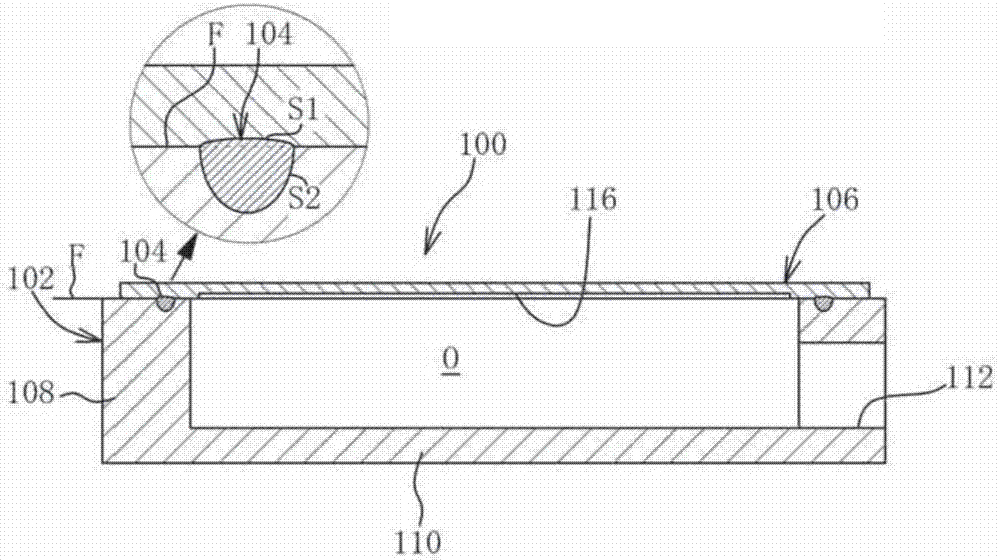

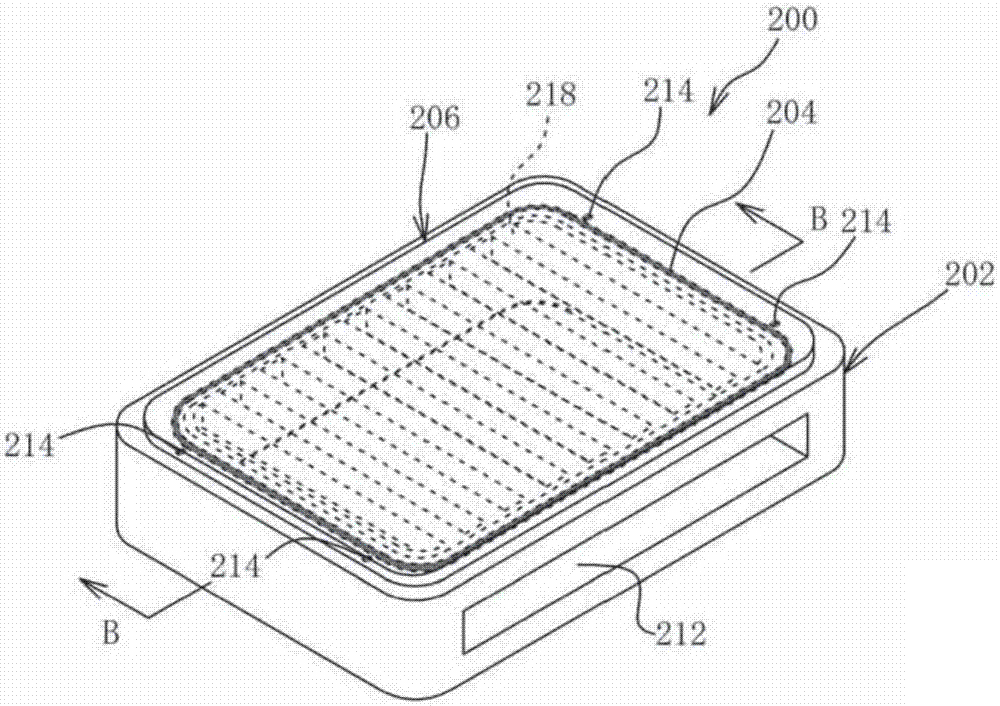

[0142] An example of applying the present invention to a connector will be described. Figures 10(a) and 10(b) show a connector as an example of the joining structure 200 of the embodiment shown in Figures 2(a) and 2(b), and Figure 10(a) is a perspective view, Fig. 10(b) is a cross-sectional view along the fitting direction X. In the figure, the corresponding members or parts are indicated by adding "'" to the symbols, and repeated descriptions are omitted.

[0143] The connector 200' is fixed to a board in an electronic device such as a mobile device or an information device, and is a receptacle connector that is connected to a connector on the counterpart side (not shown) inserted in the mating direction X, and mainly includes: The housing 202' of the absorptive member 202; a plurality of contacts 203 each extending in the mating direction X and arranged in a direction orthogonal to the mating direction X; and a thin plate as the light-transmitting member 206 The shaped cover ...

no. 2 Embodiment

[0150] An example of applying the present invention to a sensor will be described. Figs. 11(a) and 11(b) show a sensor as an example of the joined structure 300 of the embodiment shown in Fig. 4(a), Fig. 11(a) is a perspective view, and Fig. 11(b) is a cross section Figure.

[0151] The sensor 300' can be any type of sensor such as an acceleration sensor, a vibration sensor, an angular velocity sensor, a distance sensor, a position sensor, etc. The sensor 300' mainly includes: a frame 302' as a light-absorbing member 302; and a cover 306' as a light-transmitting member 306, which covers and seals the opening O'of the frame 302', and is not shown The main body of the detector (sensor chip) is housed in the housing 302'.

[0152] The frame 302' is formed of a light-absorbing thermoplastic resin, and includes a peripheral wall 308' and a bottom wall 310' that define an opening O'and protrude forwardly with a suction tube 312'.

[0153] The cover 306' is covered on the peripheral wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com