Food processing additive blending device

A technology of food processing and additives, which is applied in mixers with rotating stirring devices, transportation and packaging, mixers, etc., can solve the problems of uneven mixing and blending, increase the mixing and blending time, and slow dissolution, so as to improve the mixing efficiency , improve the deployment effect, increase the effect of stirring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

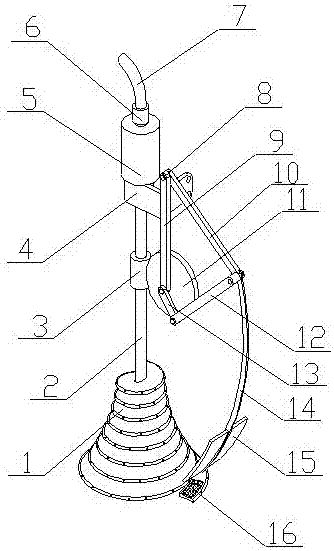

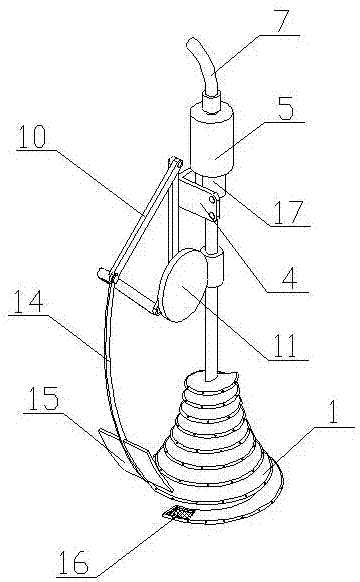

[0022] A food processing additive compounding device of the present invention is realized in this way. When in use, when compounding food additives, the L-shaped plate (4) is first installed and fixed on a suitable Position, then place the spiral blade (1) in the external mixing cylinder, inject various additive solutions into the liquid injection pipe (7) in sequence, the additive solution flows into the hollow shaft, and then flows into the rotating shaft through the connecting pipe (17). inside the tube (2), and then flow into the inside of the screw blade (1) through the through hole on the other end of the rotating tube (2), the additive solution flows along the screw blade (1), and then passes through the multi- The two through holes flow into the external mixing cylinder, and the large particle sediment in the additive solution flows along the screw blade (1) to the position of the filter screen (16) at the end of the screw blade (1), at the same time, the hollow shaft m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com