A Novel Hydrate Kinetic Inhibitor

A technology of kinetic inhibitor and hydrate inhibitor, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of loss of inhibitory effect, poor water solubility, etc., to reduce the generation rate, reduce the cost of reagents, and broaden the Applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

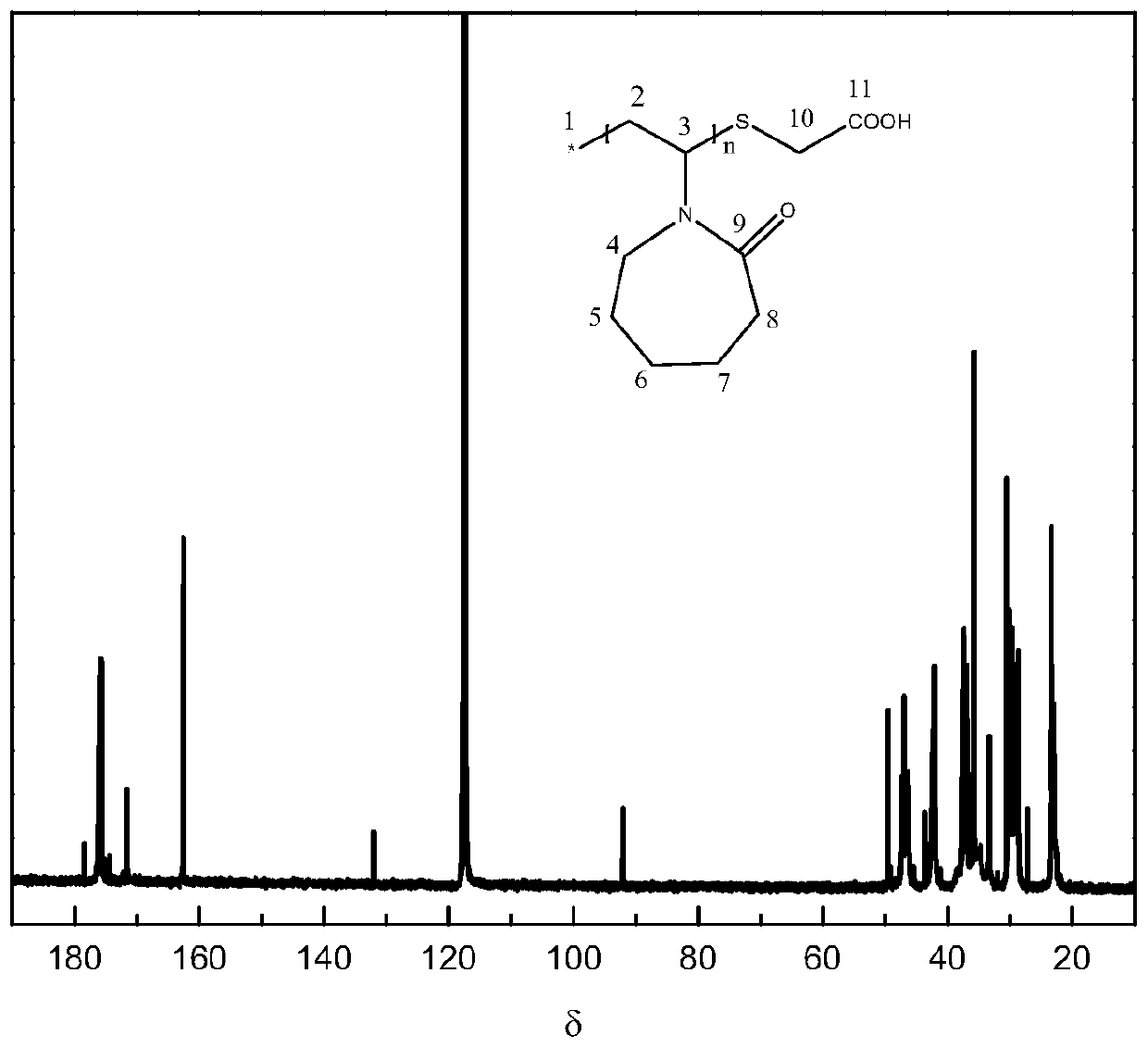

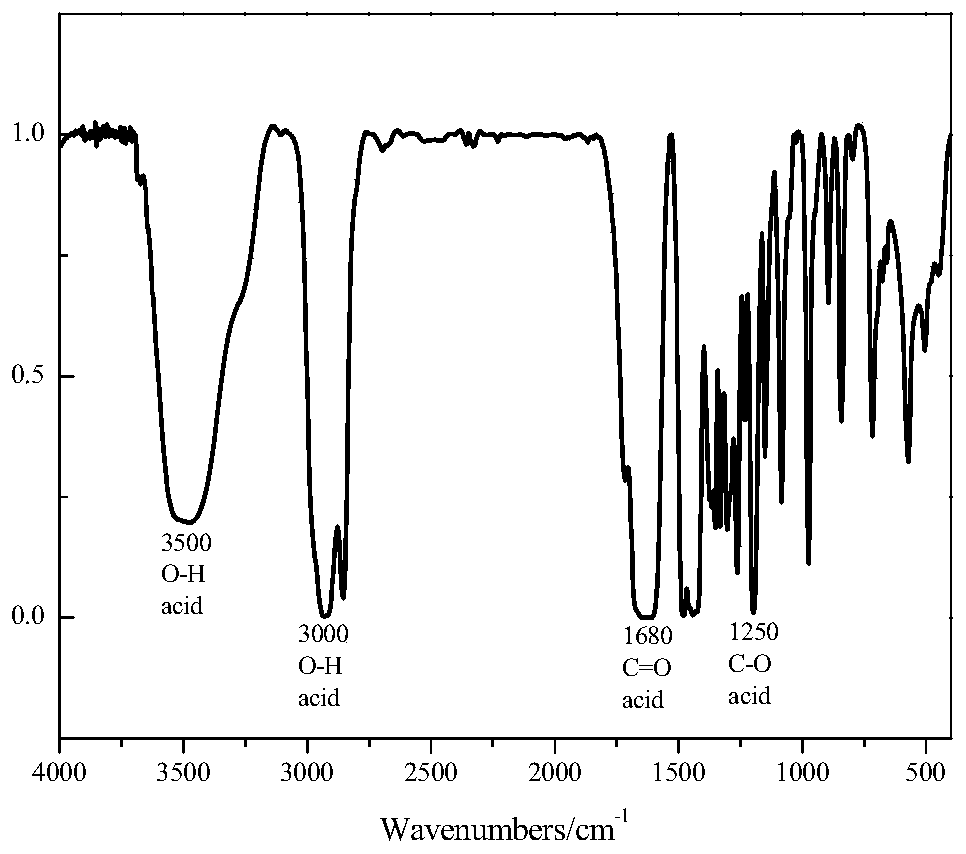

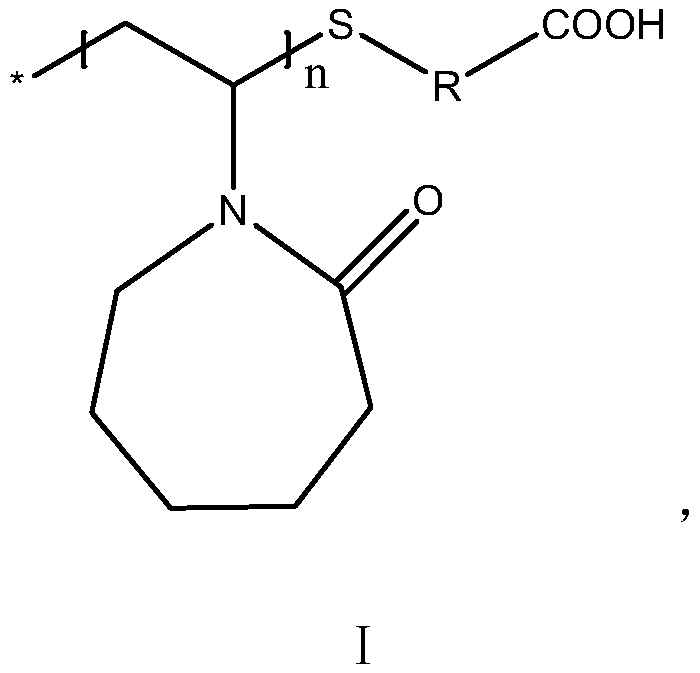

[0025] Embodiment 1: Synthesis of the hydrate kinetic inhibitor (abbreviated as PVCSCOOH) whose structural formula is shown in formula II

[0026]

[0027] Among them, the average value of n is 115.

[0028] The synthesis method includes the following steps: weigh 176 mg of chain initiator azobisisobutyronitrile, 10 g of N-vinyl caprolactam monomer, measure 0.28 mL of thioglycolic acid, and 50 mL of N,N-dimethylformamide in 100 mL of eggplant Shaped reaction bottle, sealed with a rubber stopper, vacuumed-nitrogen 3 times, then frozen with liquid nitrogen-pumped-heating cycle 3 times; reacted in an oil bath at 80°C for 12 hours in a nitrogen atmosphere; the obtained primary product was cooled After reaching room temperature, it was slowly dropped into 500mL cold ether for recrystallization and suction filtration. The obtained solid was dried in a vacuum oven at 45°C for 48 hours and then at 105°C for 1 hour to obtain the target product weight average molecular weight (Mw ) ...

Embodiment 2

[0029] Embodiment 2: inhibition effect evaluation

[0030] The evaluation method of inhibitory effect of the present invention is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com