Large-area and high-quality graphene transferring method

A transfer method and graphene technology, applied in the field of material science, can solve problems such as easy breakage and damage, graphene polymer residues, and graphene films are prone to wrinkles, and achieve the effect of low resistance and high-quality transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

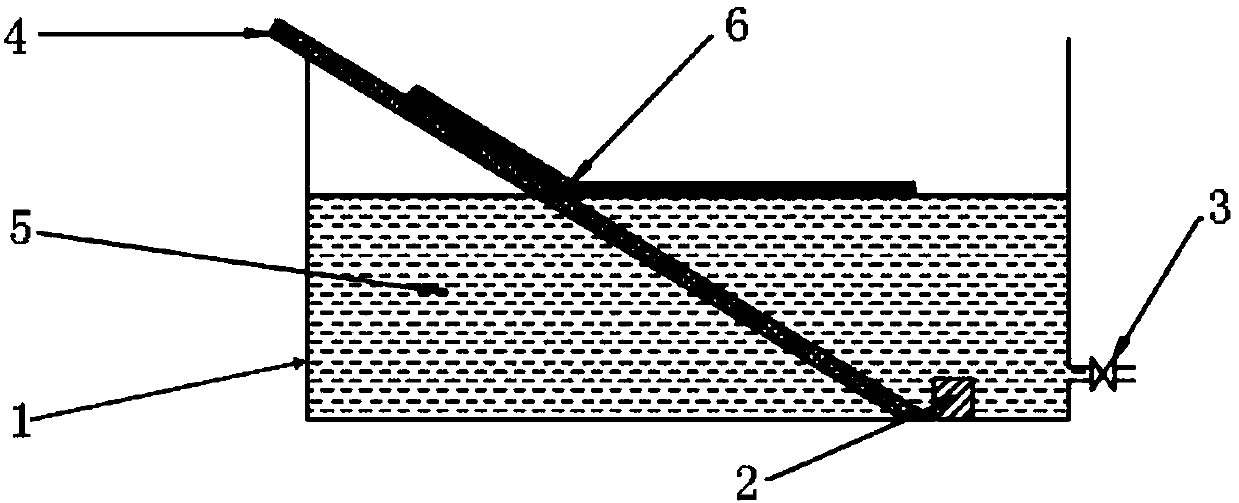

Image

Examples

Embodiment 1

[0035] A method for transferring large-area high-quality graphene, comprising the steps of:

[0036] (1) Using Cu as the growth substrate, graphene was prepared by chemical deposition. Cut the grown graphene / Cu of 50cm*50cm, spread the graphene / Cu on a clean and smooth glass, and clamp the graphene / Cu with another piece of the same glass. Pass the rolling group, the rolling speed is 5cm / min, so that the graphene / Cu is flattened.

[0037] (2) Place the flattened graphene / Cu on the conveyor belt and transmit it at a speed of 2cm / s. At the same time, the conveyor belt is provided with a PMMA spraying array, and the PMMA slurry is evenly sprayed on the graphite by the PMMA spraying array in the transmission process. On one surface of ene / Cu. Wherein, the PMMA content in the PMMA slurry is 1.5% (w / w), the solvent is ethyl acetate, and the spraying speed is 10mL / s.

[0038] (3) Heat the PMMA-coated graphene / Cu on a heating platform. At this time, do not feed nitrogen to pressuriz...

Embodiment 2

[0049] A method for transferring large-area high-quality graphene, comprising the steps of:

[0050] (1) Using Cu as the growth substrate, graphene was prepared by chemical deposition. Cut the grown graphene / Cu of 50cm*50cm, spread the graphene / Cu on a clean and smooth glass, and clamp the graphene / Cu with another piece of the same glass. Pass the rolling group, the rolling speed is 2cm / min, so that the graphene / Cu is flattened.

[0051] (2) Place the flattened graphene / Cu on the conveyor belt and transmit it at a speed of 8cm / s. At the same time, the conveyor belt is provided with a PMMA spraying array, and the PMMA slurry is uniformly sprayed on the graphite by the PMMA spraying array in the transmission process. On one surface of ene / Cu. Wherein, the PMMA content in the PMMA slurry is 1% (w / w), the solvent is ethyl acetate, and the spraying speed is 5mL / s.

[0052] (3) Heat the PMMA-coated graphene / Cu on a heating platform. At this time, do not feed nitrogen to pressuriz...

Embodiment 3

[0062] A method for transferring large-area high-quality graphene, comprising the steps of:

[0063] (1) Using Cu as the growth substrate, graphene was prepared by chemical deposition. Cut the grown graphene / Cu of 50cm*50cm, spread the graphene / Cu on a clean and smooth glass, and clamp the graphene / Cu with another piece of the same glass. Pass the rolling group, the rolling speed is 3cm / min, so that the graphene / Cu is flattened.

[0064] (2) Place the flattened graphene / Cu on the conveyor belt and transmit it at a speed of 10cm / s. At the same time, the conveyor belt is provided with a PMMA spraying array, and the PMMA slurry is evenly sprayed on the graphite by the PMMA spraying array in the transmission process. On one surface of ene / Cu. Wherein, the PMMA content in the PMMA slurry is 3% (w / w), the solvent is ethyl acetate, and the spraying speed is 8mL / s.

[0065] (3) Heat the PMMA-coated graphene / Cu on a heating platform. At this time, do not feed nitrogen to pressurize,...

PUM

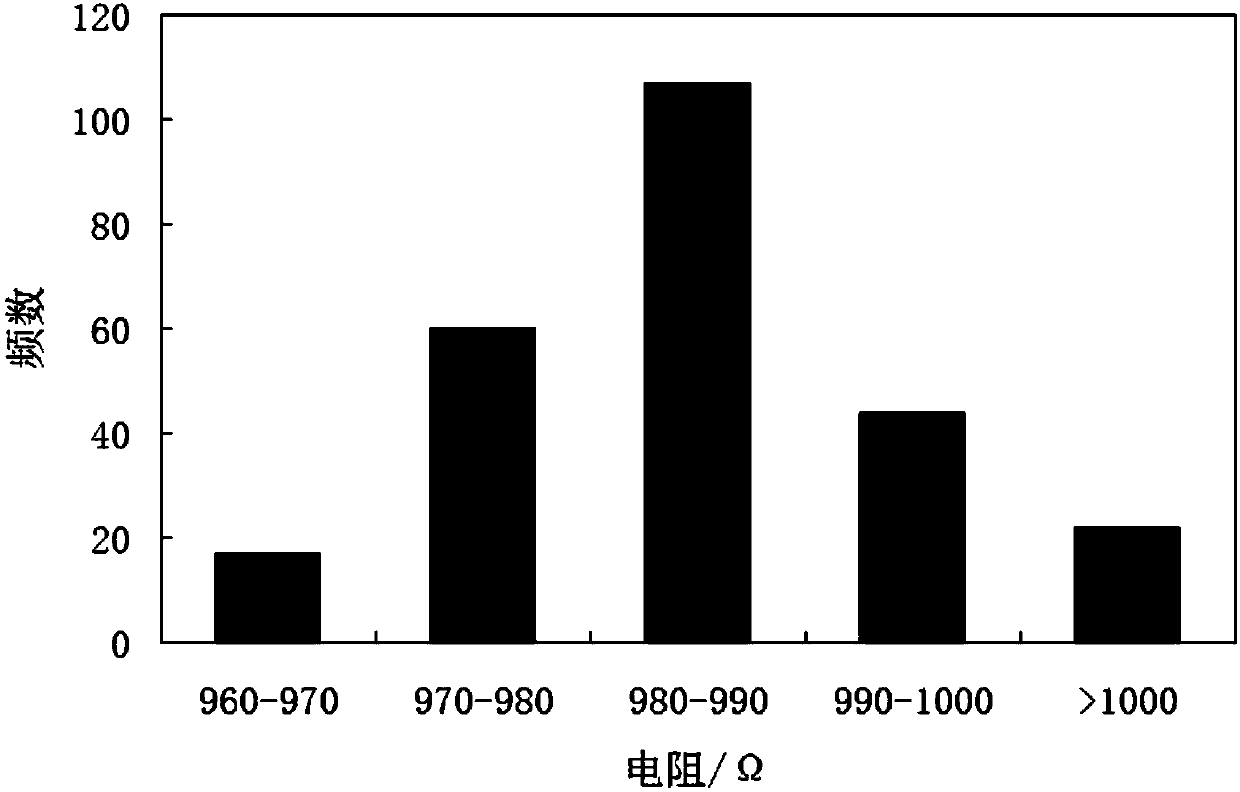

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com