Purification method of titanium alloy spherical powder for low-temperature resistant structural member

A spherical powder and titanium alloy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems that affect the low temperature performance of alloy structural parts, the sealing system cannot completely isolate the outside air, and contact with air, so as to ensure the vacuum degassing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

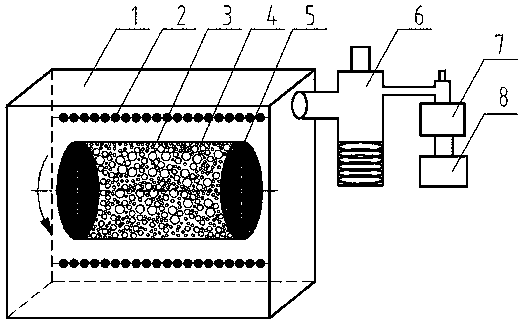

[0020] see figure 1 A method for purifying titanium alloy spherical powder for low temperature resistant structural parts, comprising the following steps:

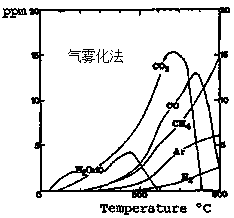

[0021] 1) Put the Ti-5A1-2.5Sn alloy spherical powder 4 prepared by the gas atomization method in an open titanium alloy cylinder, and the container mouth is covered with a screen whose mesh diameter is smaller than the minimum particle size of the powder;

[0022] 2) Place the container in a vacuum chamber with a heatable rotating device, evacuate the vacuum chamber 1, and rotate the titanium alloy cylinder 3 at the same time;

[0023] 3) When the pressure in the vacuum chamber is less than 10 -3 Pa, turn on the heating system, heat the powder to 600°C for 8 hours, and keep the pressure in the vacuum chamber less than 10 -2 Pa;

[0024] 4) After the holding time is over, turn off the heating system, and when the temperature of the powder drops below 75°C, open the vacuum chamber, take out the powder and vacuum pack it....

Embodiment 2

[0029] A method for purifying titanium alloy spherical powder for low temperature resistant structural parts, comprising the following steps:

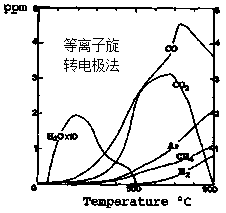

[0030] 1) Put the Ti-5A1-2.5Sn alloy spherical powder prepared by the plasma rotating electrode method in an open titanium alloy cylinder, and the container mouth is covered with a screen whose mesh diameter is smaller than the minimum particle size of the powder;

[0031] 2) Put the container in the vacuum chamber 1 with a heatable rotating device, evacuate the vacuum chamber, and rotate the titanium alloy cylinder at the same time;

[0032] 3) Wait until the pressure in the vacuum chamber is less than 5×10 -3 Pa, turn on the heating system, heat the powder to 800°C for 4 hours, and keep the pressure in the vacuum chamber less than 10 -2 Pa;

[0033] 4) After the holding time is over, turn off the heating system, and when the temperature of the powder drops below 50°C, open the vacuum chamber, take out the powder and vacuum pack it....

Embodiment 3

[0037] A method for purifying titanium alloy spherical powder for low temperature resistant structural parts, comprising the following steps:

[0038] 1) Put the Ti-5A1-2.5Sn alloy spherical powder prepared by the gas atomization method in an open titanium alloy cylinder, and the container mouth is covered with a screen whose mesh diameter is smaller than the minimum particle size of the powder;

[0039] 2) Place the container in a vacuum chamber with a heatable rotating device, evacuate the vacuum chamber, and rotate the titanium alloy cylinder at the same time;

[0040] 3) When the pressure in the vacuum chamber is less than 10 -4 Pa, turn on the heating system, heat the powder to 400°C for 4 hours, then raise the temperature to 700°C for 2 hours, and keep the pressure in the vacuum chamber less than 10 -3 Pa;

[0041] 4) After the holding time is over, turn off the heating system, and when the temperature of the powder drops below 25°C, open the vacuum chamber, take out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com