Optical mixer based on super-surface materials and preparation method of optical mixer

An optical mixer and metasurface technology, applied in optics, instruments, optical components, etc., can solve problems such as large insertion loss, complicated manufacturing process, and difficult implementation in the laboratory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The embodiment of the present invention also provides a method for preparing an optical mixer based on a metasurface material, comprising the following steps:

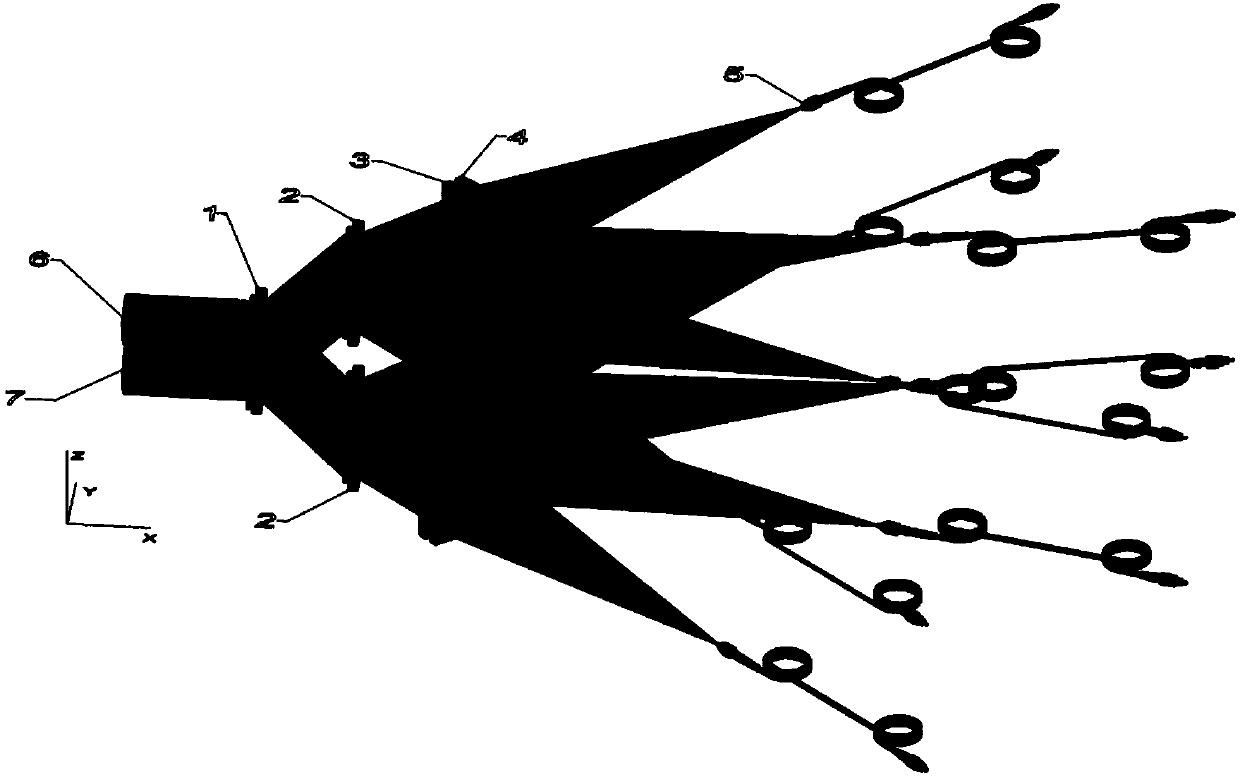

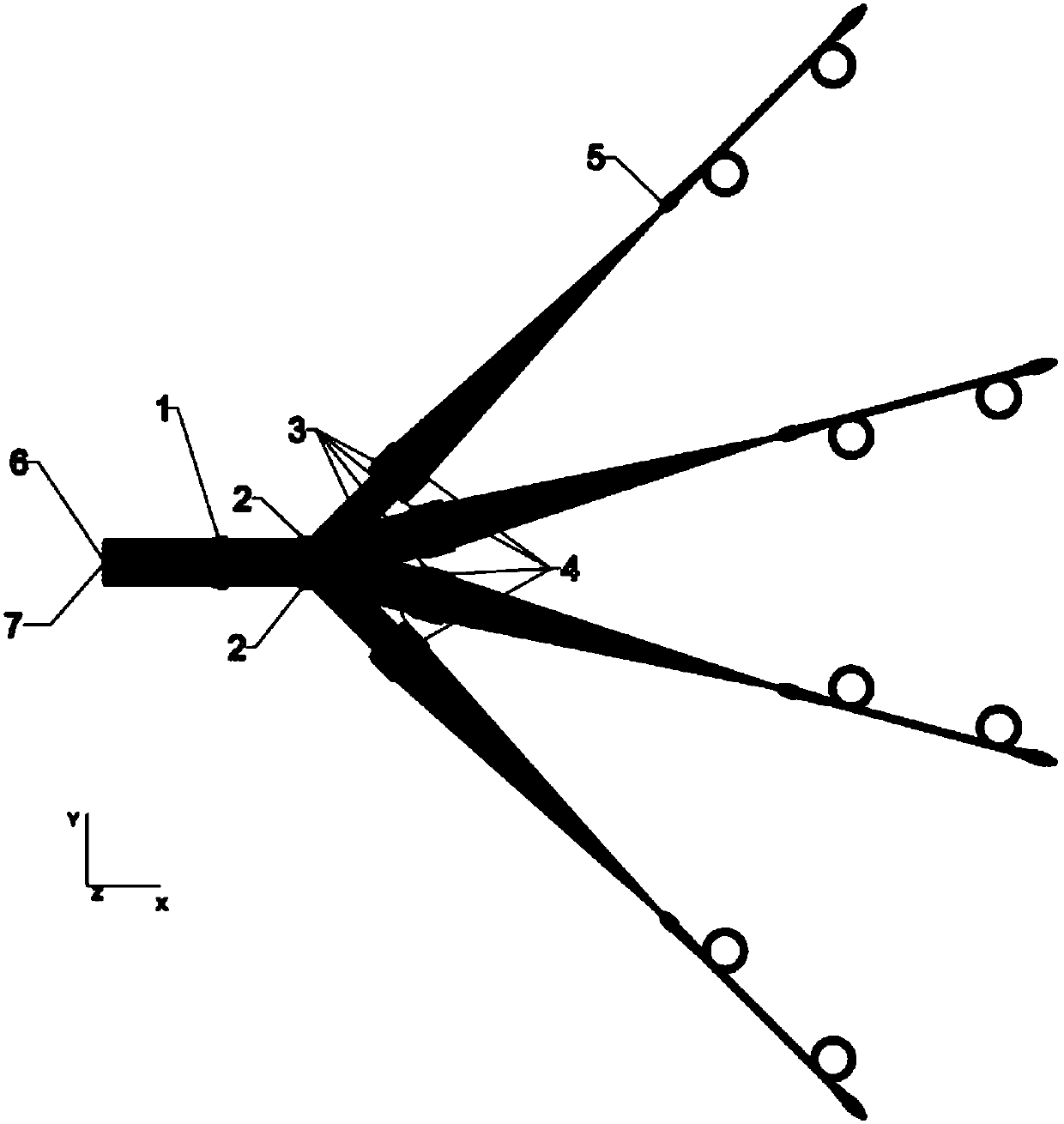

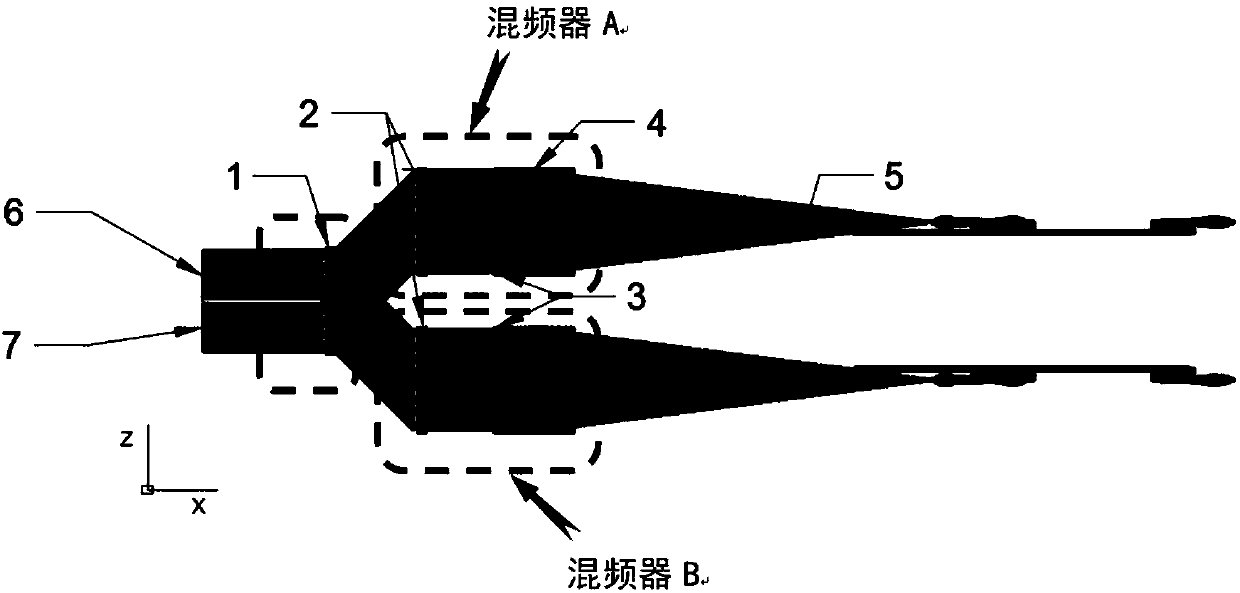

[0087] S1. Set the following parameters: signal light diameter, local oscillator light diameter, fiber numerical aperture, length and width of circularly polarized beam splitter 1, length and width of spatial beam splitter 2, length and width of phase shifter, and square lens The focal length, length, width, radius of curvature of the mirror surface, distance between vertices, the overall length, width and height of the optical mixer, the signal light or local oscillator light is decomposed into two left-handed beams with a diffraction angle of 45 degrees after passing through the circular polarized beam splitter 1 And right-handed circularly polarized light, each beam of circularly polarized light is divided into four after passing through the spatial beam splitter, the divergence angle is 90 degrees, and the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com