Carbon black tail gas incineration boiler with carbon black dry waste gas treatment function

A tail gas incineration and waste gas treatment technology, applied in the boiler field, can solve the problems of high environmental protection pressure, waste of investment cost, increase the dosage of Nox reagents, etc., achieve the goal of reducing environmental protection pressure of emissions, low investment and operating costs, and promoting simultaneous development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

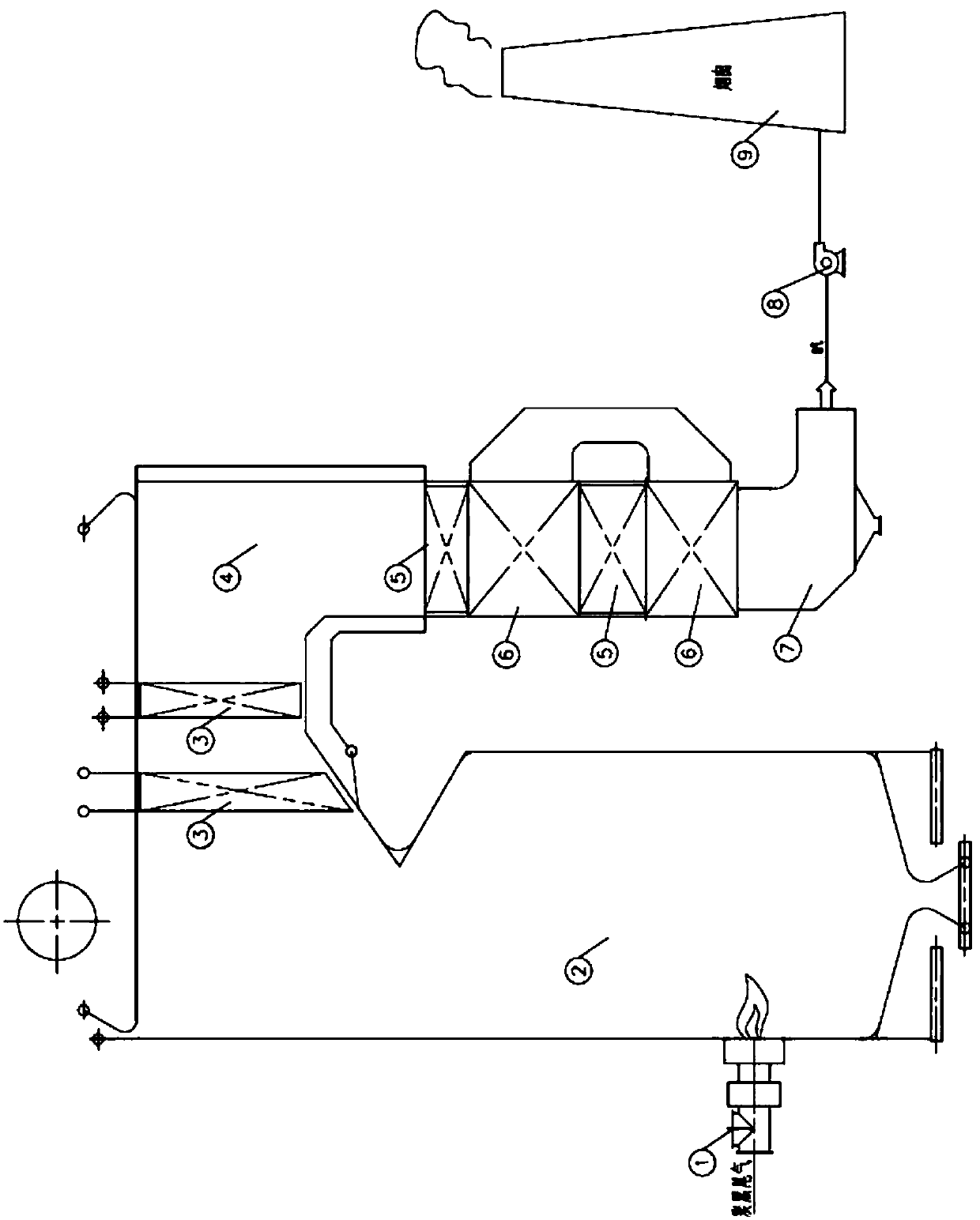

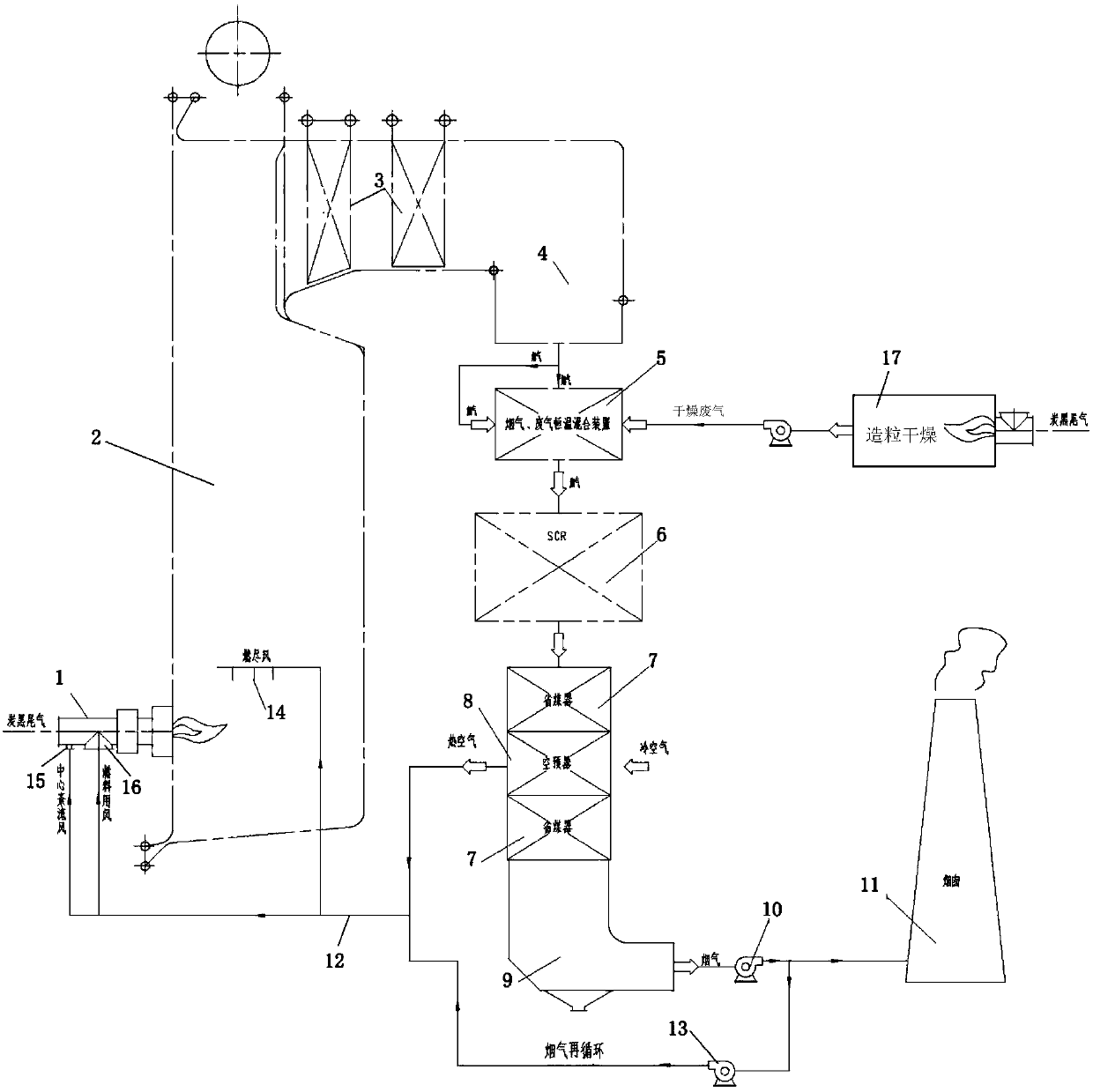

[0019] like Figure 1 to Figure 4 As shown, a carbon black tail gas incineration boiler with carbon black drying waste gas treatment includes a carbon black tail gas incineration boiler body and a flue gas discharge pipeline. It also includes a dry waste gas branch 17 and flue gas, waste gas constant temperature mixing device 5, one of the inlets of the flue gas and waste gas constant temperature mixing device is connected with the flue gas outlet of the main body of the carbon black tail gas incineration boiler through a pipeline, and introduced into the carbon black tail gas incineration boiler The flue gas of the main body, the other inlet is connected with the exhaust gas outlet of the dry exhaust gas branch, and the dry exhaust gas is introduced. The outlet of the flue gas and exhaust gas constant temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com