Automobile headlamp

A car headlight, the other side of the technology, applied in the direction of headlights, motor vehicles, road vehicles, etc., can solve the problems of complex structure of headlights, unsatisfactory heat dissipation, etc., to simplify the space layout, reduce the burnt bad possible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

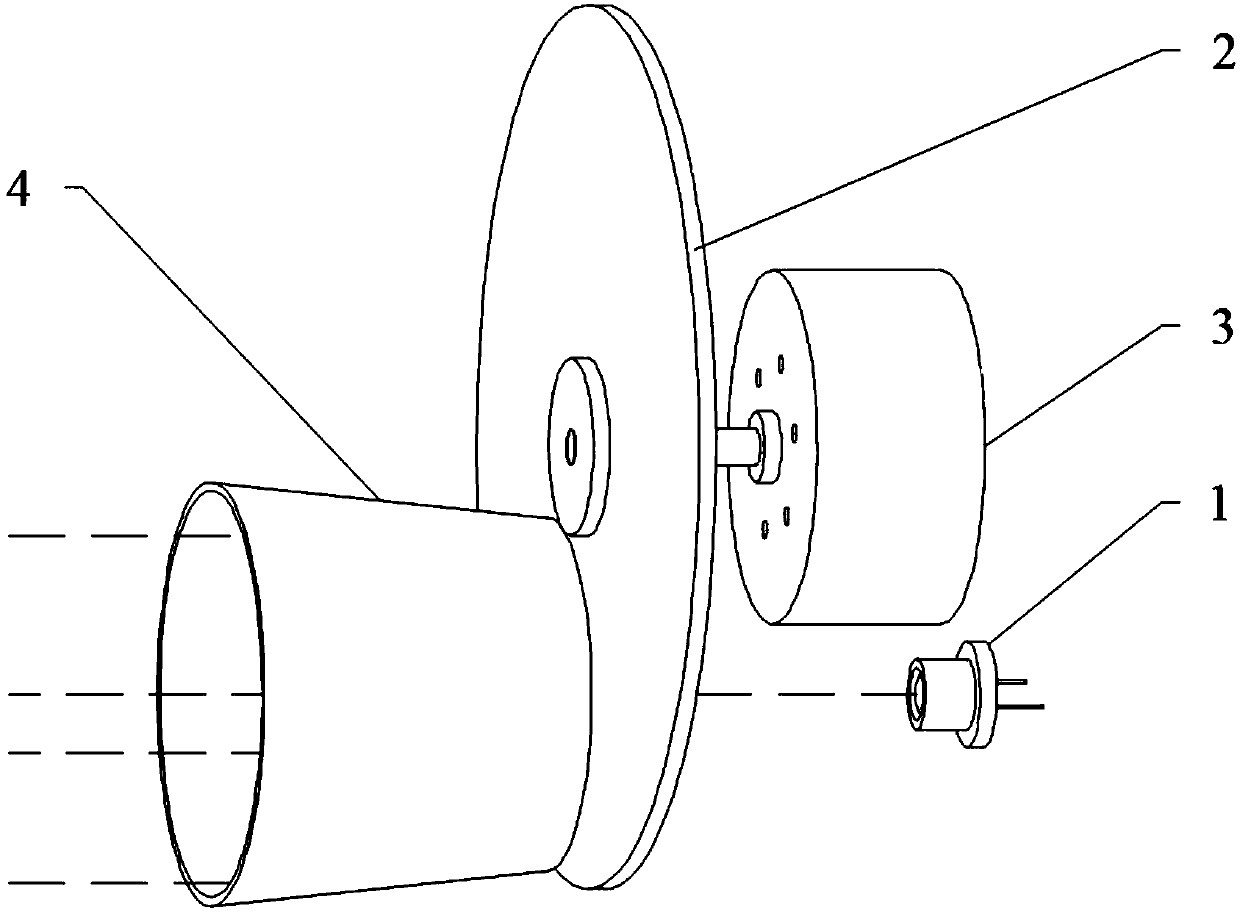

[0012] A car headlight, such as figure 1 As shown, it includes a laser light source 1 , a fluorescent sheet 2 , a rotating mechanism 3 and a reflector 4 . The fluorescent sheet 2 is fluorescent ceramic glass, the middle part of the fluorescent sheet 2 is connected with the rotating mechanism 3, the fluorescent sheet 2 can rotate under the drive of the rotating mechanism 3, and the rotation axis is perpendicular to the surface of the fluorescent sheet 2; one side of the fluorescent sheet 2 has a laser The light source 1 and the laser light source 1 adopt laser diodes, and the light radiation direction of the laser light source 2 faces the fluorescent sheet 2; During work, the fluorescent sheet 2 rotates driven by the rotating mechanism 3, the laser light source 2 projects laser light to the fluorescent sheet 2, excites the fluorescent material on the fluorescent sheet 2 to generate diffused light, and the diffused light is projected to the reflector 4, and then projected outwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com