Unit seamless switching manner

A seamless switching and unit technology, which is applied in mechanical equipment, pipeline systems, gas/liquid distribution and storage, etc., can solve the problems of well site production impact and gas cut-off, and achieve the effect of reducing impact and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

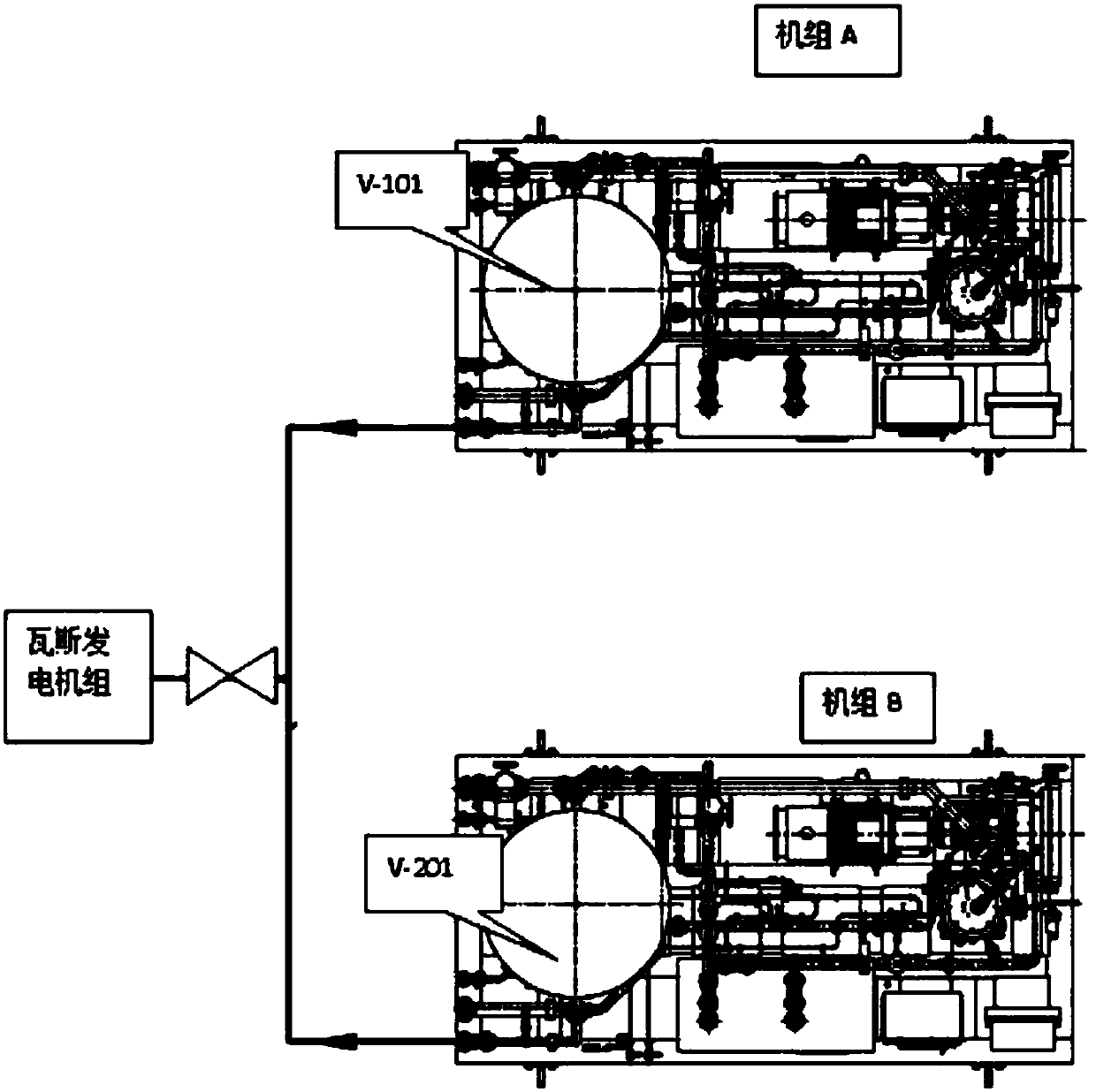

[0012] The compressed pressure of the screw machine of the present invention is 0.8 MPaG. After the compression, the gas first enters the storage tank, and then enters the gas generating set for use through the pressure regulation of the pressure regulating valve.

[0013] When unit A stops abnormally, unit B automatically detects the running state of the main motor, and when the main engine of A does not work, it will start unit B immediately, and it will reach full load and normal operation within 5 minutes, which can prevent the gas at the rear end of the screw machine The generator set shuts down, effectively ensuring the stability and reliability of production.

[0014] To sum up, the present invention makes full use of the compressibility of gas, uses storage tanks to store gas, and enables the rear-end generator set to switch compressor units without stopping, which can greatly improve the stability and reliability of the gas generator set, and make Uninterrupted normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com