Environment-friendly flame-retardant ethylene-propylene-diene monomer rubber vibration-absorptive material and preparation method thereof

A technology of EPDM rubber and EPDM rubber, which is applied in the field of flame-retardant and shock-absorbing rubber, can solve the problems of reduced fatigue resistance of rubber materials, poor damping performance of EPDM rubber, and reduced performance of rubber materials, etc., to achieve The internal structure is compact and orderly, the compatibility and combination are strong, and the effect of good damping and shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

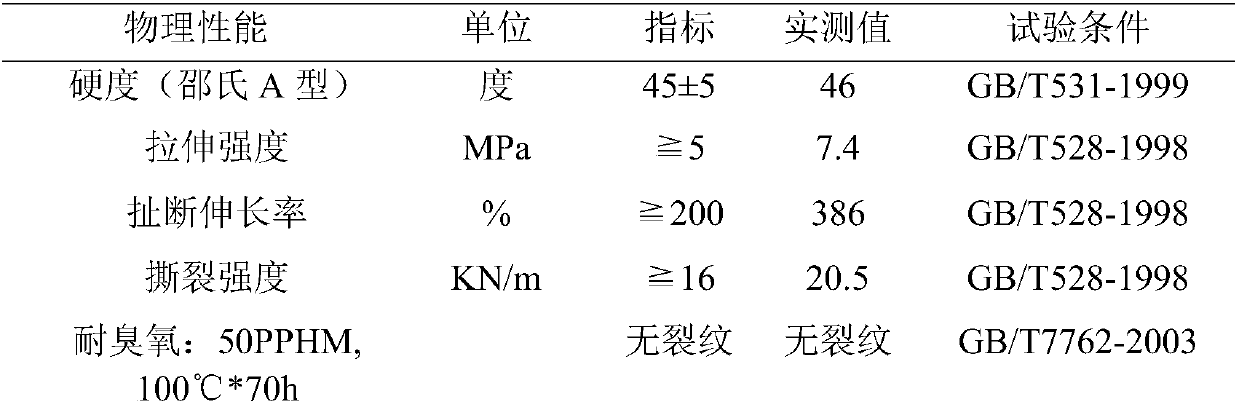

[0016] An environmentally friendly flame-retardant EPDM shock-absorbing material, including the following components in parts by weight: EPDM rubber 185, N550 carbon black 15, red phosphorus flame retardant RL-EP 12, modified magnesium hydroxide Powder 85, aluminum hydroxide 150, white carbon black 12, naphthenic oil 35, antioxidant RD 4, zinc oxide 9, zinc stearate 2.0, active agent PEG-4000 1.5, magnesium oxide 4.5, release agent L- 242.5, release agent KL-3Q 1.5, vulcanizing agent S-80 1.5, accelerator 4.

[0017] The accelerators used are 1 part of accelerator DM, 1 part of accelerator DPTT-70, 1 part of accelerator ZDBC-75, and 1 part of accelerator CBS.

[0018] The modified magnesium hydroxide powder is obtained by blending, melting and granulating nano-scale magnesium hydroxide and a modifier according to a weight ratio of 1:0.01, and then pulverizing it, and its particle size is 0.1 micron. The neutralizing agent is made of maleic anhydride, EPDM rubber and benzoyl p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com