Single-component high-temperature self-crosslinking waterborne polyurethane preparation method

A water-based polyurethane and self-crosslinking technology, which is applied in the coating and other directions, can solve the problems of poor storage stability of the emulsion, unsatisfactory crosslinking effect, short service life of the emulsion at high temperature, etc., and achieve excellent physical and mechanical properties, excellent water resistance, and long life. Effect of High Temperature Service Life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

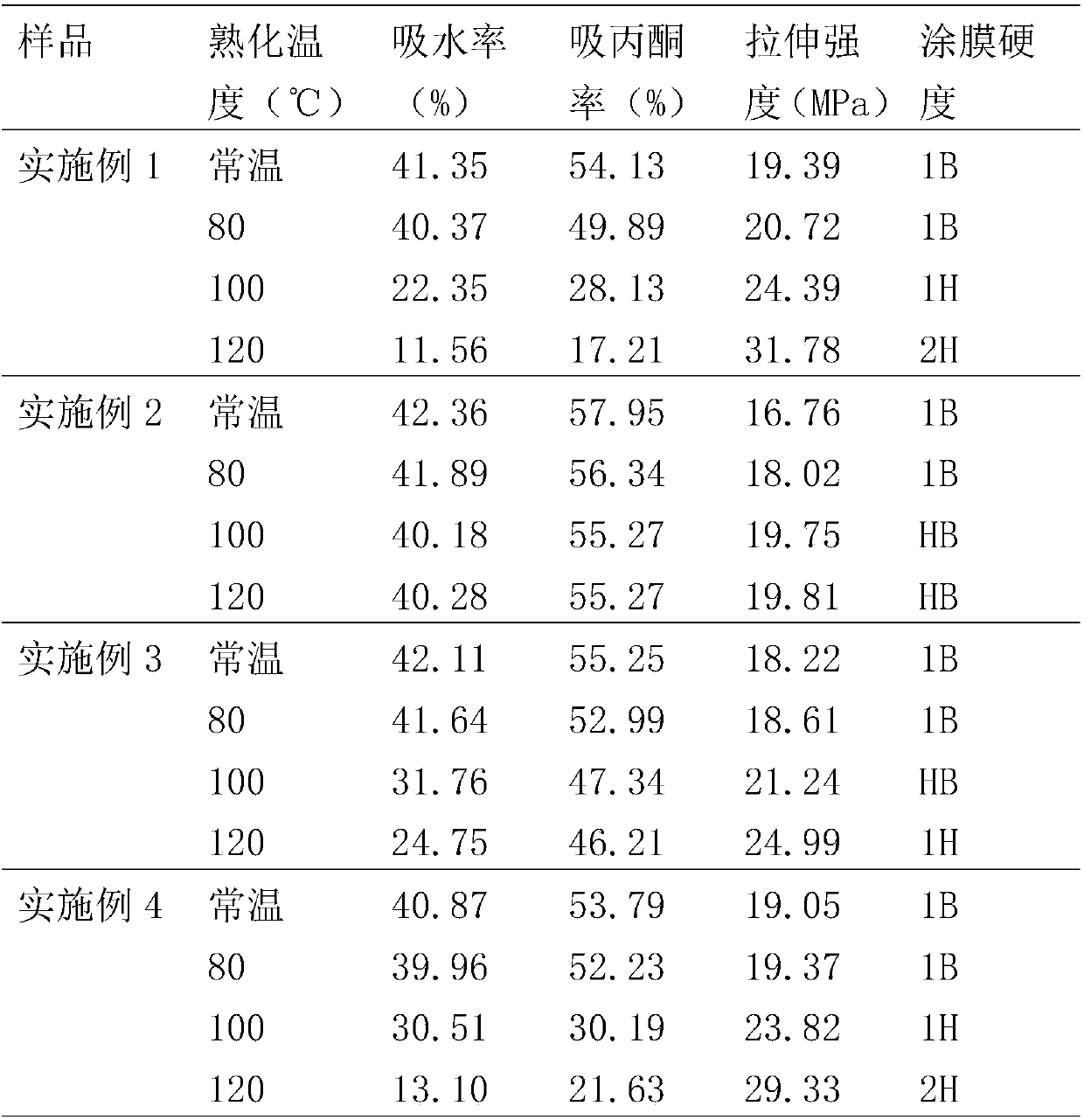

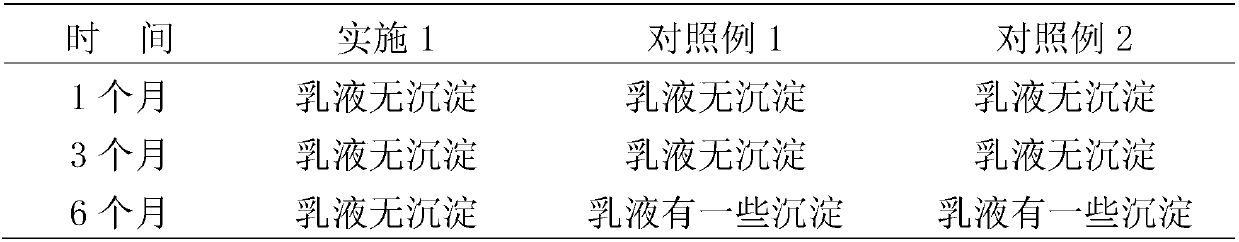

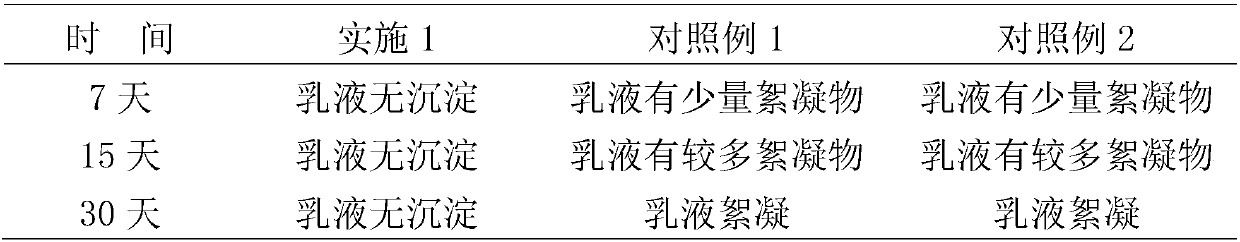

Examples

Embodiment 1

[0031] (1) Synthesis of waterborne polyurethane

[0032]Add 30 parts of Pol-2356 (hydroxyl value 54-56 mg KOH / g, produced by Qingdao Yutian Chemical Industry Co., Ltd.), 1 part of trimethylolpropane (Sweden Pastor Company), and 4 parts of dimethylolpropionic acid in the reaction kettle. (DMPA) hydrophilic agent (Swedish Pastor company), heat up to 70°C under full stirring, add 25 parts of isophorone diisocyanate, heat up to 75-85°C for 3-5 hours, add 8 parts The end-capping agent hydroxyethyl acrylate reacted for 2 to 3 hours, then cooled to 50°C, added 2 parts of salt-forming agent, salted for 10 minutes, added 120 parts of deionized water, stirred for 60 minutes, and discharged to obtain the required water-based Polyurethane.

[0033] (2) Synthesis of oxazoline-polyacrylate / waterborne polyurethane copolymer emulsion

[0034] A. Preparation of pre-emulsion

[0035] Take 100 parts of the synthesized water-based polyurethane, add 70 parts of deionized water, 2 parts of emuls...

Embodiment 2

[0039] Repeat the step method of embodiment 1, just do not add 2-vinyl-2-oxazoline in the copolymerization synthesis, other are all the same as embodiment 1.

Embodiment 3

[0041] Repeat the step method of Example 1, but add 2 parts of 2-vinyl-2-oxazoline in the copolymerization, and the others are all Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com