Alkali-free setting accelerator containing coagulation and early-strength accelerator and organic amine substance and preparation method thereof

A technology of accelerating coagulation, early strength, and organic amines, applied in the field of alkali-free accelerators and their preparation, can solve the problems of increased strength retention rate, concrete structure damage, strong alkalinity of accelerators, etc., and can reduce expansion and cracking. Possibility, reduce the late strength loss, improve the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

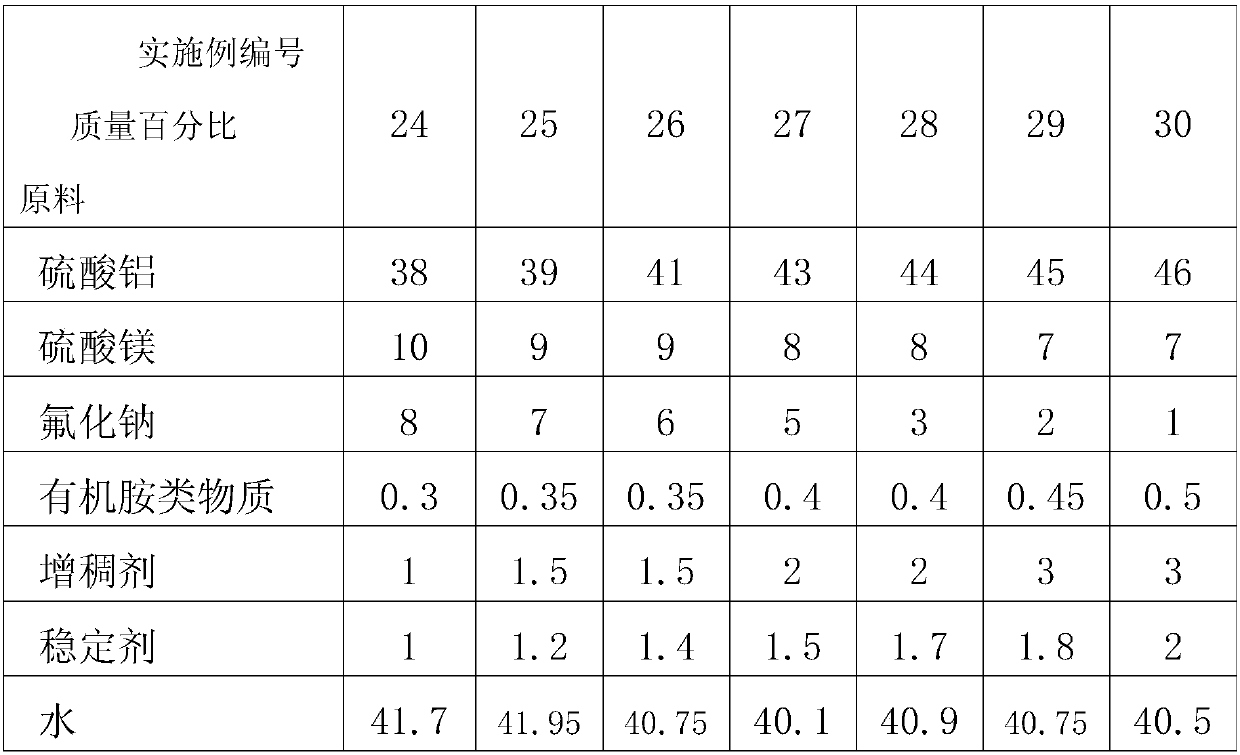

Examples

Embodiment 1

[0036]A kind of non-alkali quick-setting agent containing coagulation accelerating agent organic amines and preparation method thereof, is: in the 500ml three-necked or four-necked flask that is equipped with stirring, condensing, heating device, add the aluminum sulfate 40g that grinds, Magnesium sulfate 8g and deionized water 36.5g, heat up to 65°C, stir to dissolve while heating, add 5g of sodium fluoride at the same time, stir to form a uniform and stable system, then add 0.28g of triisopropanolamine, 2g of polyacrylamide, 1.5 g of tartaric acid, stirred rapidly for 30-60 minutes, and cooled to room temperature to obtain a non-alkali quick-setting agent containing an organic amine substance as a coagulation accelerator (hereinafter referred to as an alkali-free liquid accelerator). The main performance indicators when the accelerator content is 7%, clean slurry: initial setting time is 2.42min, final setting time is 7.41min; mortar: 1d compressive strength 15.6MPa, 28d comp...

Embodiment 2

[0038] A kind of non-alkali quick-setting agent containing coagulation accelerating agent organic amines and preparation method thereof, is: in the 500ml three-necked or four-necked flask that is equipped with stirring, condensing, heating device, add the aluminum sulfate 42g that grinds, Magnesium sulfate 10g and deionized water 35g, heat up to 80°C, stir and dissolve while heating to form a uniform and stable system, then add 0.3g of diethanol monoisopropanolamine, 3g of polyacrylamide, 2g of citric acid, stir rapidly for 30 After ~60min, cool down to room temperature to obtain the alkali-free liquid accelerator. The main performance indicators when the accelerator content is 7%, clean slurry: initial setting time is 2.31min, final setting time is 7.24min; mortar: 1d compressive strength 17.2MPa, 28d compressive strength ratio is 90.7%.

Embodiment 3

[0040] A kind of non-alkali quick-setting agent containing coagulation accelerating agent organic amines and preparation method thereof, is: in the 500ml three-necked or four-necked flask that is equipped with stirring, condensing, heating device, add the aluminum sulfate 38g that grinds, Magnesium sulfate 12g and deionized water 34g, heat up to 65°C, stir to dissolve while heating, add 3g of sodium fluoride at the same time, stir to form a uniform and stable system, then add 0.25g of triisopropanolamine, 5g of polyacrylamide, tartaric acid 2g, stirred rapidly for 30-60min, cooled to room temperature, and the alkali-free liquid quick-setting agent was obtained. The main performance indicators when the accelerator content is 7%, clean slurry: initial setting time is 2.54min, final setting time is 7.46min; mortar: 1d compressive strength 14.4MPa, 28d compressive strength ratio is 87.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com