Stainless steel pipe production waste water zero discharge cyclic utilization system

A technology for the production of wastewater and stainless steel pipes, which is applied in the direction of water pollutants, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of less investment, waste of water resources, environmental pollution, etc., to save site area and reduce treatment costs , The effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

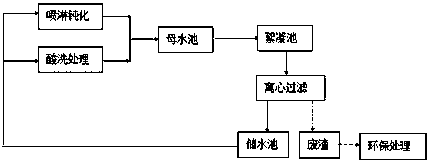

[0025] Such as figure 1 As shown, a zero-discharge recycling system for stainless steel pipe production wastewater, including a mother water tank, a flocculation tank, a centrifugal filter, and a water storage tank connected in sequence; a filtration system is installed at the connection end between the mother water tank and the centralized pipeline, and the waste water enters after being filtered Mother pool; the wastewater in the mother pool is transported to the flocculation tank for flocculation; the wastewater after flocculation enters the centrifugal filter, and the water and flocculation sediment are separated by centrifugal filtration, and the treated wastewater enters the storage tank for the next stage. Recycling application, the waste residue can be treated in an environmentally friendly manner.

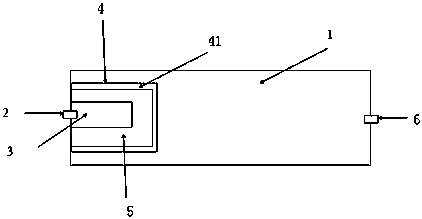

[0026] Such as figure 2As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com