Preparation method and product of cobalt manganese sulfide electrocatalyst

A cobalt-manganese sulfide electrocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of less cobalt-manganese sulfide, achieve low cost, simple operation process, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention relates to a preparation method of a cobalt manganese sulfide electrocatalyst and a cobalt manganese sulfide electrocatalyst prepared by the method. The aforementioned method includes the following core steps:

[0031] i. Take cobalt salt, manganese salt and urea, and dissolve the weighed cobalt salt, manganese salt and urea in water, and stir to obtain a uniform solution;

[0032] ii. placing the solution and the carrier in a reactor for hydrothermal reaction to obtain supported cobalt manganese carbonate;

[0033] iii. Place the supported cobalt-manganese carbonate in an aqueous solution containing a sulfidating agent to carry out a sulfidation reaction to obtain a supported cobalt-manganese sulfide.

[0034] It can be preferred that: the concentration of the cobalt salt is 0.05-0.2 mol / L, the molar ratio of the cobalt salt to the manganese salt is 1:5-5:1, and the total molar ratio of urea to the aforementioned metal salt is 1:1 ~3:1.

[0035] It may...

Embodiment 1

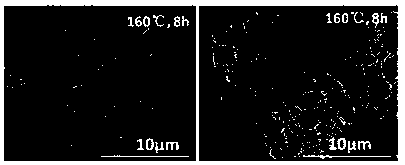

[0042] Weigh 6 mmol of cobalt nitrate, 6 mmol of manganese nitrate and 15 mmol of urea and dissolve them in 60 mL of deionized water. After the dissolution is complete, a purple-red solution is obtained. At the same time, cut out 2.5 cm*6 cm of nickel foam. Use acetone, 3mol / L hydrochloric acid and deionized water to clean it ultrasonically, then pour the mixed solution of cobalt nitrate, manganese nitrate and urea into a 100mL hydrothermal reaction kettle, and immerse the cleaned foamed nickel into the solution, and then put Put the reaction kettle into a blast oven, heat at 90°C for 12 hours, take out the nickel foam and dry it at low temperature, then pour the dried nickel foam and 60mL sodium sulfide solution (0.2mol / L) into a 100mL hydrothermal reaction kettle , put the reaction kettle into a blast oven and heat at 160°C for 8 hours, and finally take out the foamed nickel and dry it at low temperature to obtain a foamed nickel-supported cobalt-manganese sulfide electrocata...

Embodiment 2

[0045] Weigh 3 mmol of cobalt sulfate, 15 mmol of manganese sulfate and 18 mmol of urea and dissolve them in 60 mL of deionized water. After the dissolution is complete, a purple-red solution is obtained. Hydrochloric acid and deionized water are ultrasonically cleaned, and then the mixed solution of cobalt sulfate, manganese sulfate and urea is poured into a 100mL hydrothermal reaction kettle, and the cleaned carbon cloth is immersed in the solution, and then the reaction kettle is put into a blast oven Inside, heat at 80°C for 24 hours, take out the carbon cloth and dry it at low temperature, then pour the dried carbon cloth and 60mL sodium sulfide solution (0.15mol / L) into a 100mL hydrothermal reaction kettle, put the reaction kettle into the drum Heat in an air oven at 20°C for 12 hours, and finally take out the carbon cloth and dry it at low temperature to obtain a carbon cloth-supported cobalt manganese sulfide electrocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com