Feed additive and feed

A feed additive, feed technology, applied in animal feed, additional food elements, applications, etc., can solve the problems of gastrointestinal mucosal ulcers, negative effects, and high coating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

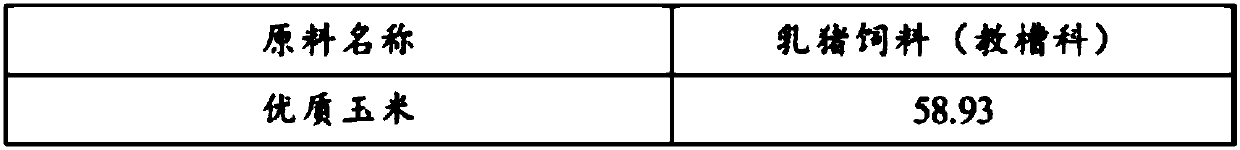

Image

Examples

Embodiment 1

[0030] Add 500kg of dichloromethane and 154kg of cysteamine into a 2000L enamel reaction kettle, cool down to 0-5°C with frozen brine, slowly add 204kg of acetyl chloride (over 30%), and drop 200kg of triethylamine at the same time to maintain the temperature Reaction at 0-5°C, when no cysteamine can be detected, stop the reaction, raise the temperature to 38-45°C, distill out dichloromethane for recovery (recycling), add 1000kg of cold water, and separate 200kg of N-acetylcysteamine , detected by liquid chromatography, the content was 99.1% (N-acetyl cysteamine standard sample was purchased from SIGMA, USA), and the yield was 97.9%.

Embodiment 2

[0032] Add 500kg of dichloromethane and 154kg of cysteamine into a 2000L enamel reaction kettle, cool down to 0-5°C with frozen brine, slowly add 277kg of butyryl chloride (over 30%), and dropwise add 200kg of triethylamine to keep the temperature Reaction at 0-5°C, when no cysteamine can be detected, stop the reaction, raise the temperature to 38-45°C, distill out dichloromethane for recovery (recycling), add 1000kg of cold water, and separate 255kg of N-butyryl cysteamine , detected by liquid chromatography, the content was 99.4% (N-butyryl cysteamine standard sample was purchased from SIGMA, USA), and the yield was 98.1%.

Embodiment 3

[0034]Add 500kg of dichloromethane and 154kg of cysteamine into a 2000L enamel reaction kettle, cool down to 0-5°C with frozen brine, slowly add 782kg of oleoyl chloride (over 30%), and drop 200kg of triethylamine at the same time to maintain the temperature Reaction at 0-5°C, when no cysteamine can be detected, stop the reaction, raise the temperature to 38-45°C, slip out the dichloromethane for recovery (recycling), add 1000kg of cold water, and separate 635kg of N-oleoyl cysteamine , detected by liquid chromatography, the content was 98.2% (N-oleoyl cysteamine standard sample was purchased from SIGMA, USA), and the yield was 96.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com