Polarizer protective film, polarizing plate comprising same, and liquid crystal display device comprising polarizing plate

A light-transparent substrate technology, applied in optical elements, polarizing elements, optics, etc., can solve the problems of reduced brightness, narrowed color reproduction area, and deterioration of color reproduction, so as to prevent the increase of haze, reduce production costs, The effect of excellent optical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

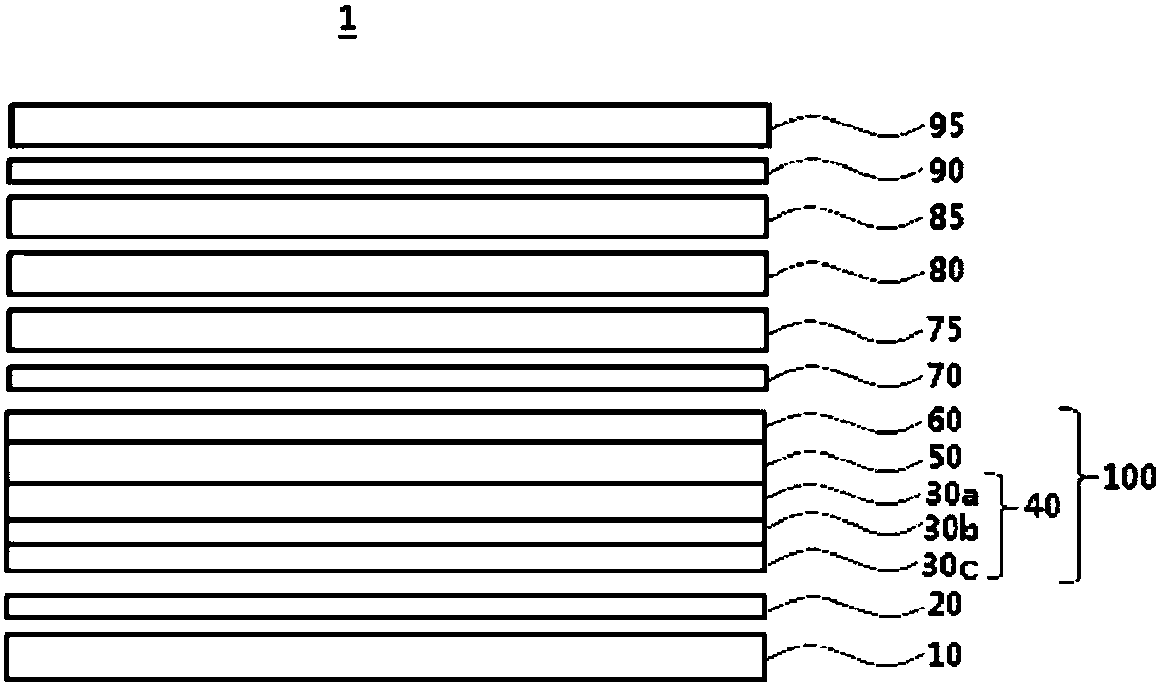

preparation example Construction

[0116] The laminate of the wide color gamut layer and the surface layer can be produced by coating the above-mentioned composition for forming the surface layer on a transparent film containing a dye or pigment having a maximum absorption wavelength of 580 nm to 610 nm, and curing the resultant conduct. A transparent film including a dye or a pigment having a maximum absorption wavelength of 580 nm to 610 nm can be prepared using the above-described composition for forming a wide color gamut layer. For example, the laminate can be produced using a method of coating the above composition for forming a wide color gamut layer on a release film, curing the resultant and then removing the release film, or using an extrusion method or the like. The release film may be removed after preparing the transparent film containing dye or pigment, or may be removed after forming a surface layer on the transparent film containing dye or pigment, or before bonding the laminate on the transpare...

Embodiment approach

[0155] Hereinafter, operations and effects of the present specification will be described in more detail with reference to specific examples of the present specification. However, such examples are for illustrative purposes only, and the scope of rights of the present disclosure is not limited thereby.

[0156]

Embodiment 1

[0158] (1) Preparation of composition A1 for forming a wide color gamut layer

[0159] 80g of trimethylolpropane triacrylate (TMPTA), 20g of hexafunctional urethane acrylate (product name: UA-306I), 1g of a porphyrin-based dye with a maximum absorption wavelength of 593nm, and 1g of photopolymerization An initiator (product name: Irgacure 184) and 100 g of methyl ethyl ketone (MEK) solvent were mixed to prepare composition A1.

[0160] (2) Preparation of Composition B1 for Forming Surface Layer

[0161] Composition B1 was prepared by solvent mixing 95 g of trimethylolpropane triacrylate, 5 g of a photopolymerization initiator (Irgacure 184), and 100 g of methyl ethyl ketone solvent (MEK).

[0162] (3) Preparation of wide color gamut film

[0163] Composition A1 was coated on a TAC film having a thickness of 60 μm so that the dried thickness became 3 μm. After drying the resultant at 60 for 2 minutes, use a mercury lamp at 150mJ / cm 2 The resultant was cured by irradia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com