Pneumatic tire for motorcycles

A technology for motorized two-wheeled vehicles and pneumatic tires, which is applied in the directions of motor vehicles, motorcycle tires, tire parts, etc., can solve the problems of tire durability damage and reduction, and achieve the effect of improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

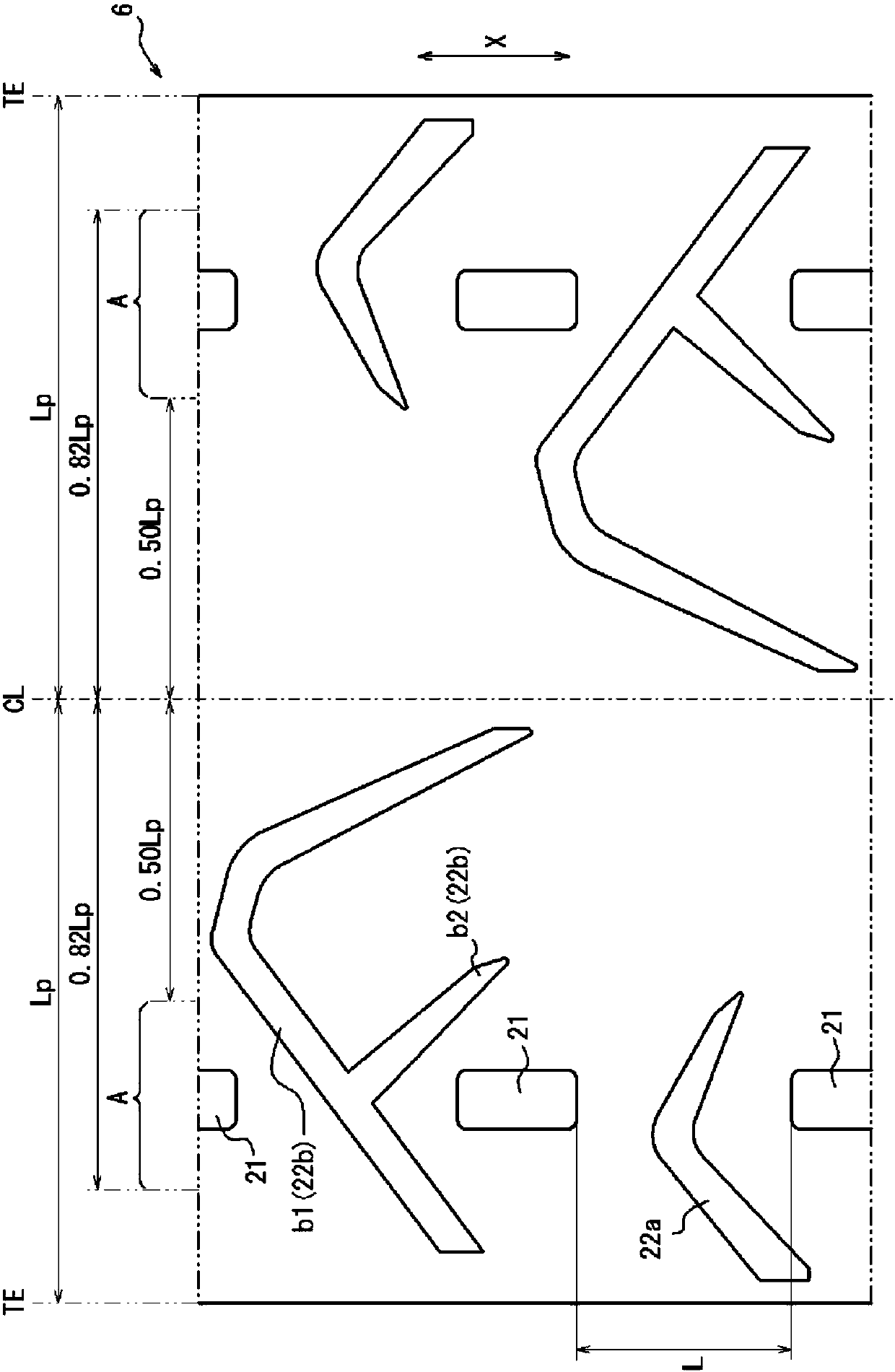

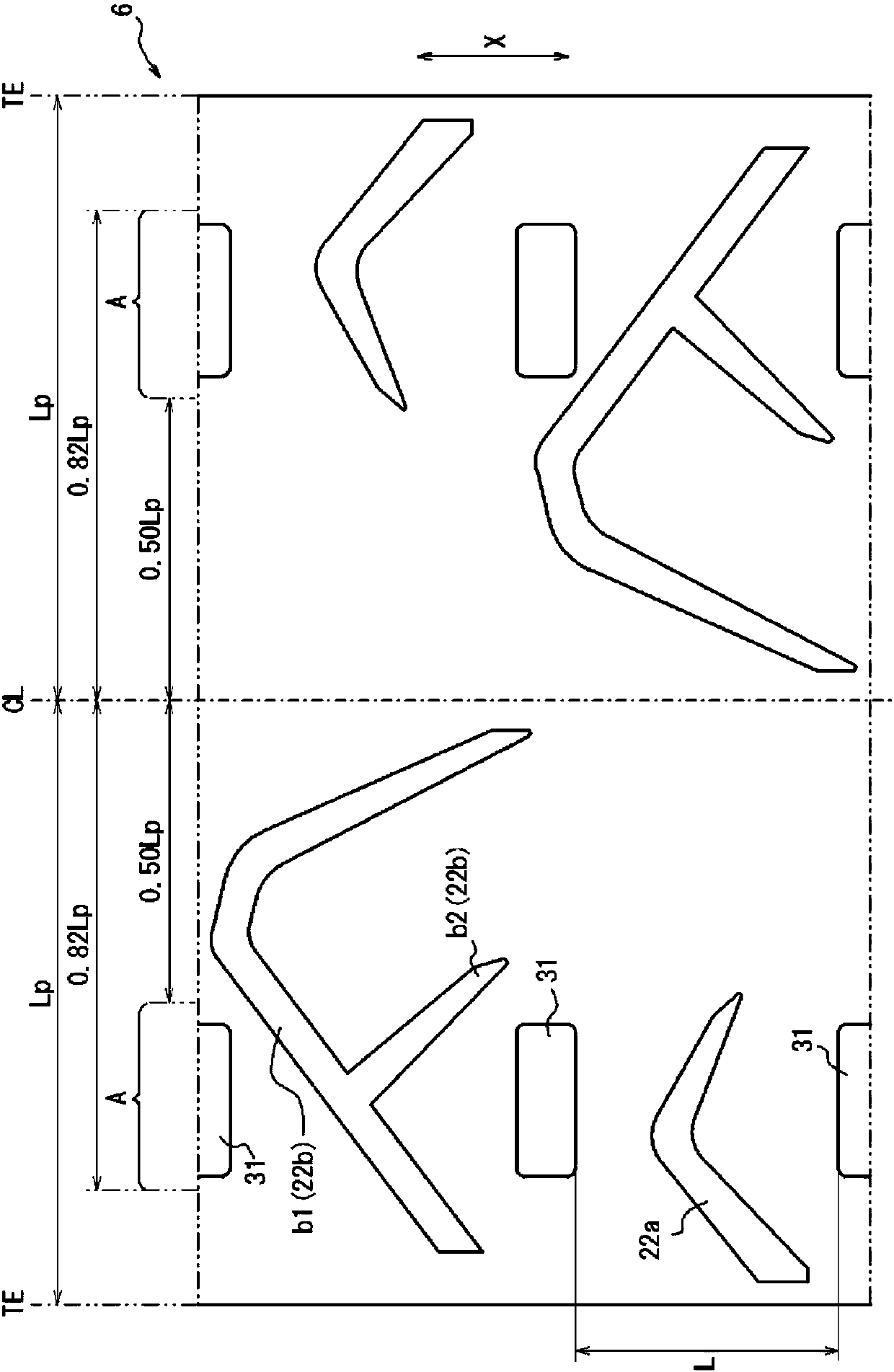

[0084] Inventive tires and comparative tires (both having a tire size of 180 / 60R16M / C) were trial-manufactured according to the specifications in Table 1, and the tires were evaluated for durability, steering stability, and uneven wear resistance. Note that in Invention Example 5 and Invention Example 12 in Table 1, since the circumferential groove 21 and the small hole 41 are arranged to overlap each other in the tire circumferential direction, the "circumferential groove 21, width direction groove 31 or small hole 41" in the table The interval L / pattern pitch" between the holes 41 is represented as 0.

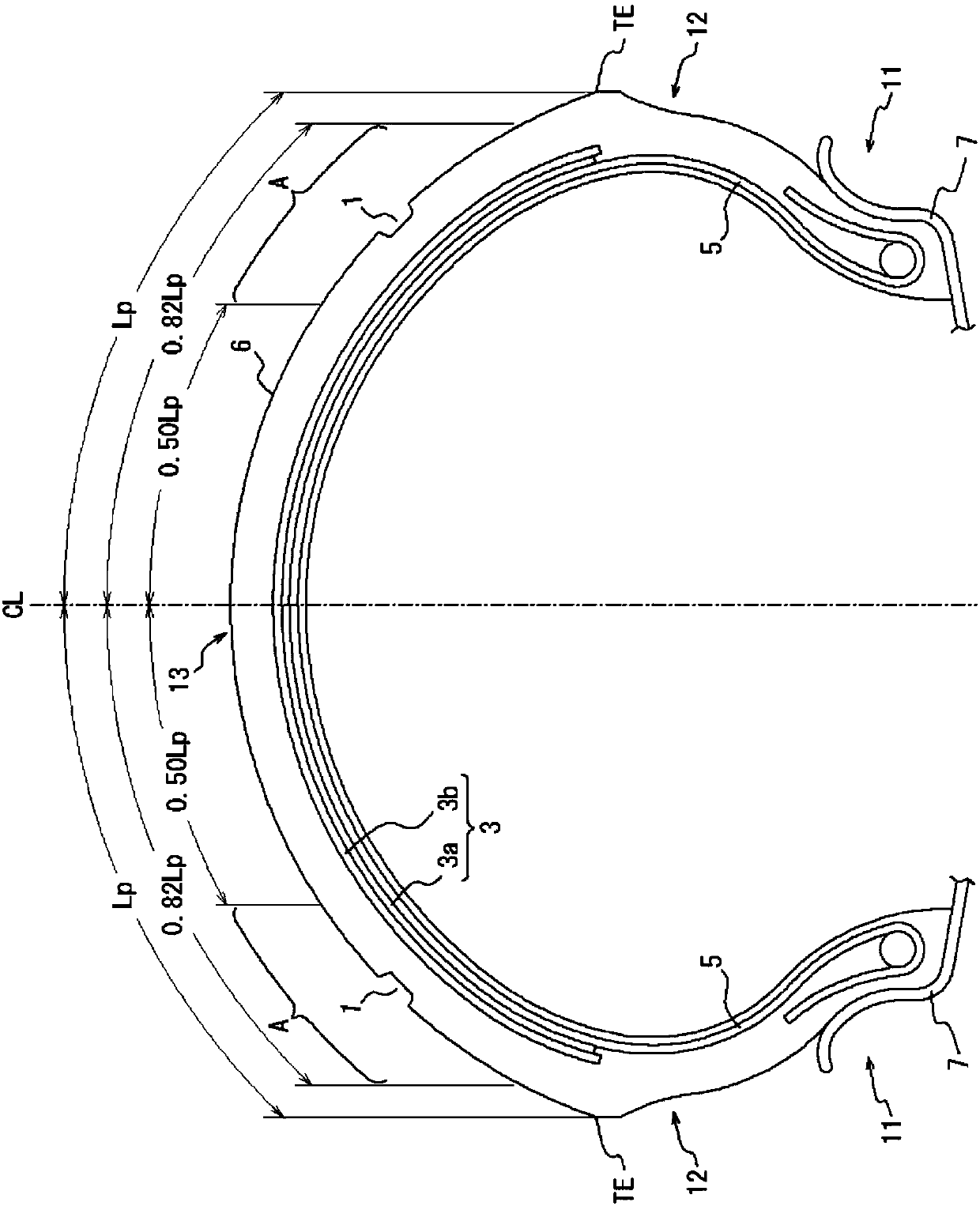

[0085] Each of the test tires includes a pair of sidewall portions located outside the pair of bead portions in the tire radial direction and a tread portion straddling between the sidewall portions, wherein the carcass straddling between the bead portions is used as skeleton. More specifically, each of the test tires included a carcass composed of two layers of plies having...

Embodiment 2

[0093] Invention tires and comparative tires (both having a tire size of 180 / 60R16M / C) were trial-manufactured according to the specifications in Table 2, and the durability, noise performance and steering stability of the tires were evaluated.

[0094] Each of the test tires includes a pair of sidewall portions located outside the pair of bead portions in the tire radial direction and a tread portion straddling between the sidewall portions, wherein the carcass straddling between the bead portions is used as skeleton. More specifically, each of the test tires included a carcass composed of two layers of plies having nylon cords, and included two layers obtained by covering aramid cords with rubber on the outer side in the tire radial direction of the carcass. A belt layer and a one-layer belt layer obtained by covering nylon cords with rubber located outside the two-layer belt layer in the tire radial direction. The cord angle of the carcass ply relative to the tire width di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumferential length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com