Electronic functional member, method for manufacturing same, and biological measurement sensor

A manufacturing method and technology of conductive parts, applied in sensors, micro-sensors, nano-sensors, etc., can solve the problems of electrode layer damage, peeling, etc., and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

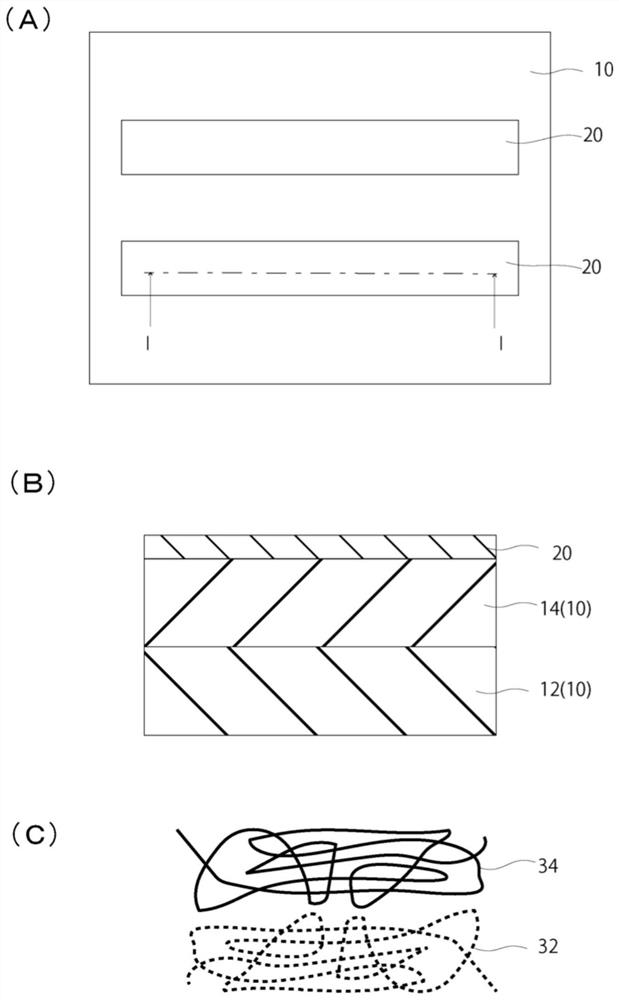

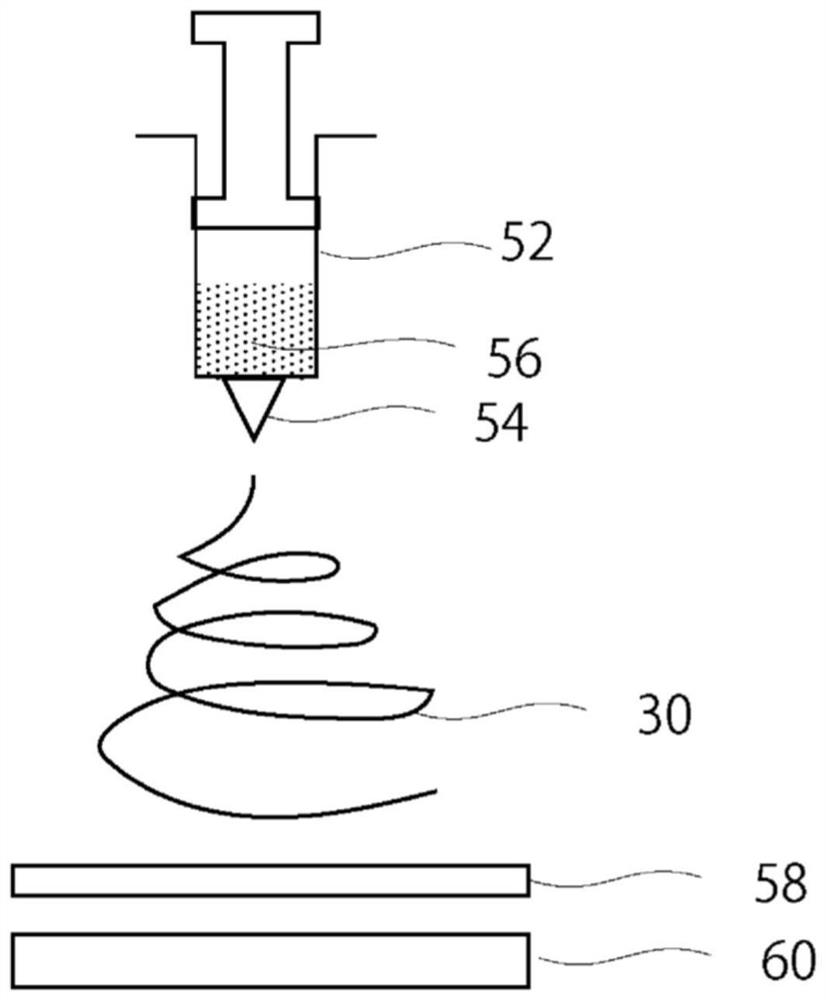

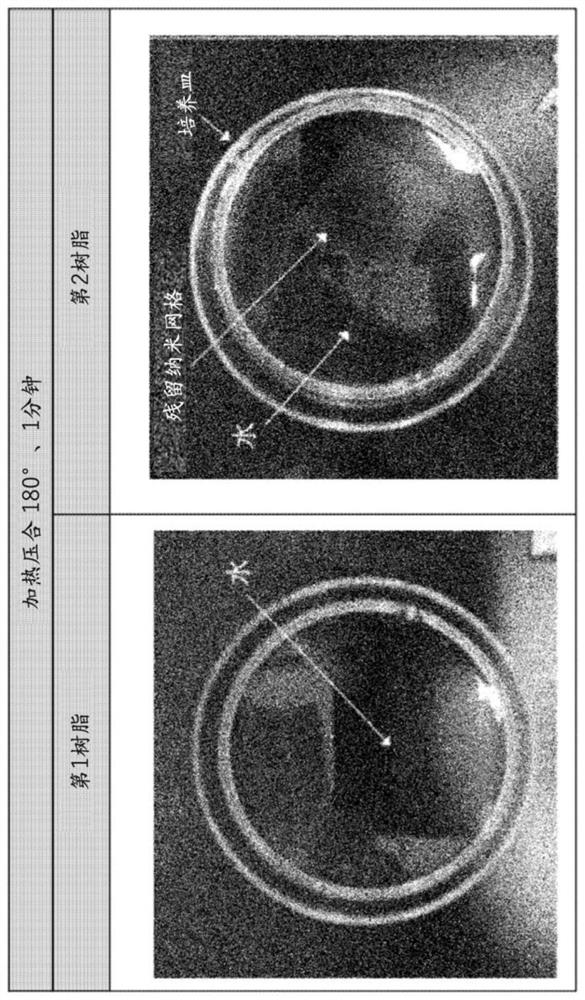

[0035] Embodiments of the present invention will be described below with reference to the drawings, but the shape, size, and arrangement relationship of each component are schematically shown to the extent that the present invention can be understood. In addition, although preferred configuration examples of the present invention will be described below, the materials, numerical conditions, and the like of each component are merely preferred examples. Therefore, the present invention is not limited to the following embodiments, and various changes and modifications can be made without departing from the scope of the constitution of the present invention, all of which can achieve the effects of the present invention.

[0036] (Structure and manufacturing method of the first electronic functional part)

[0037] refer to figure 1 and figure 2 , and the electronic functional component (hereinafter referred to as the first electronic functional component) according to the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com