Spring guided type cutting cable mechanism of low frequency cable assembly crimping system

A technology of cable assembly and guide mechanism, which is applied in the field of spring-guided wire cutting mechanism of low-frequency cable assembly crimping system, can solve the problems affecting the quality of cables, etc., and achieve the effects of improving cutting quality, low manufacturing cost, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

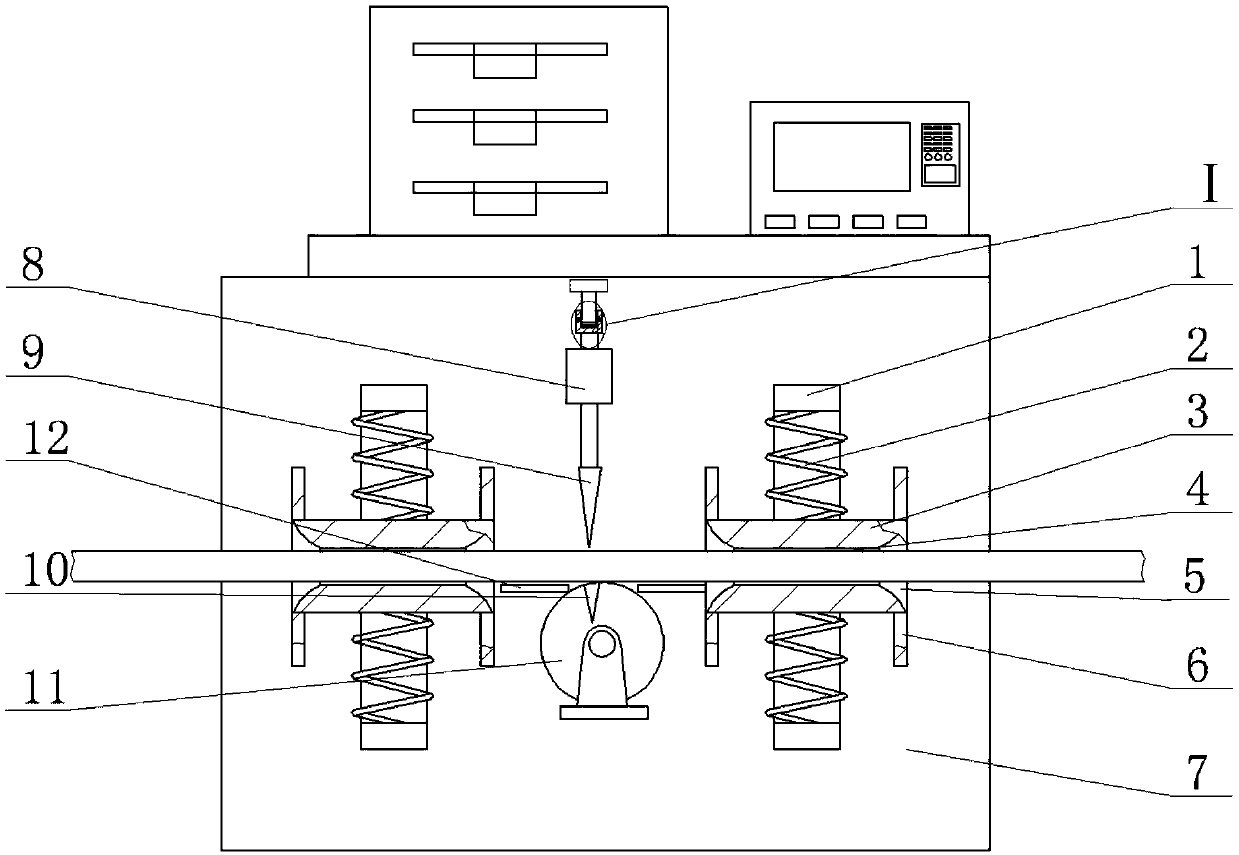

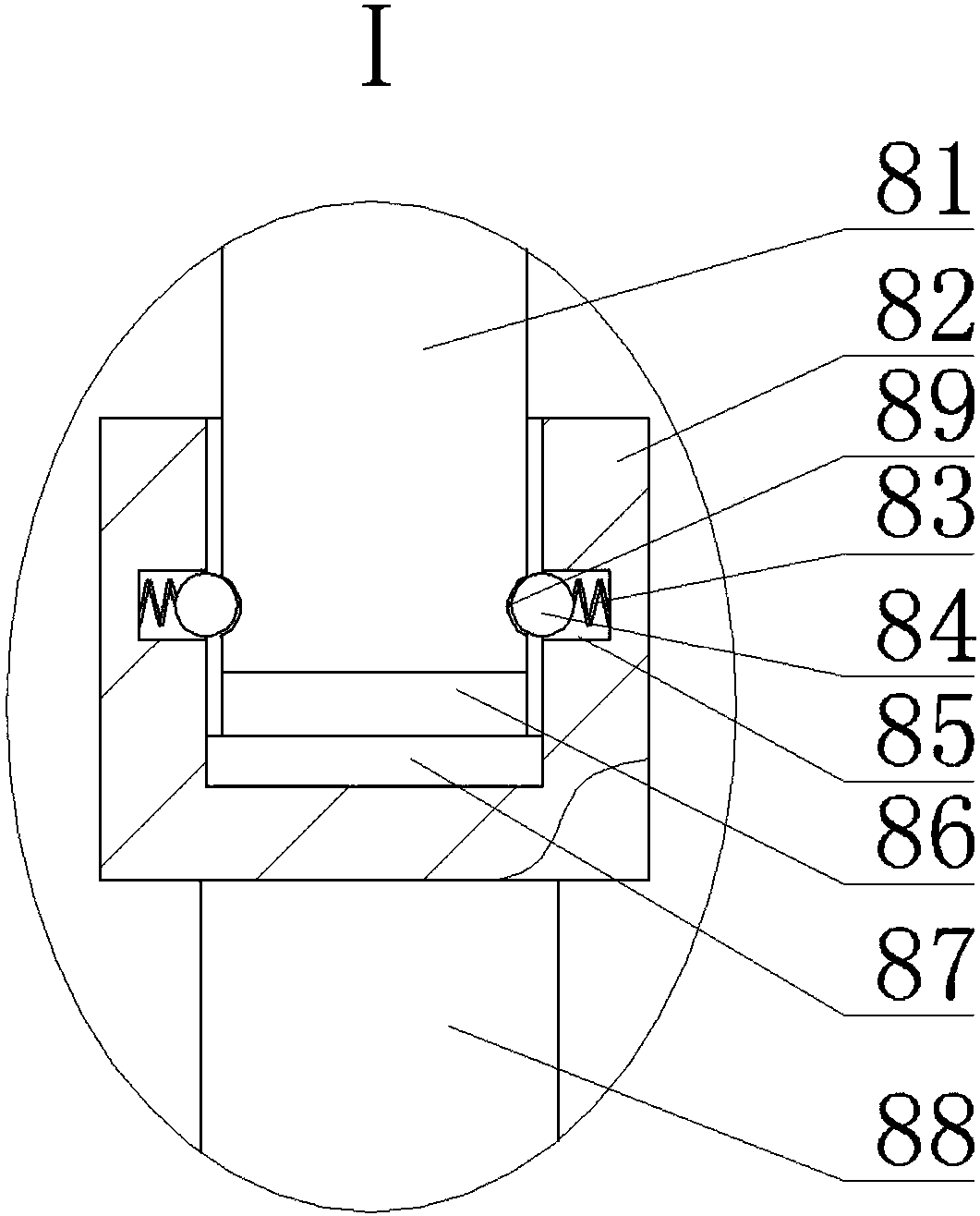

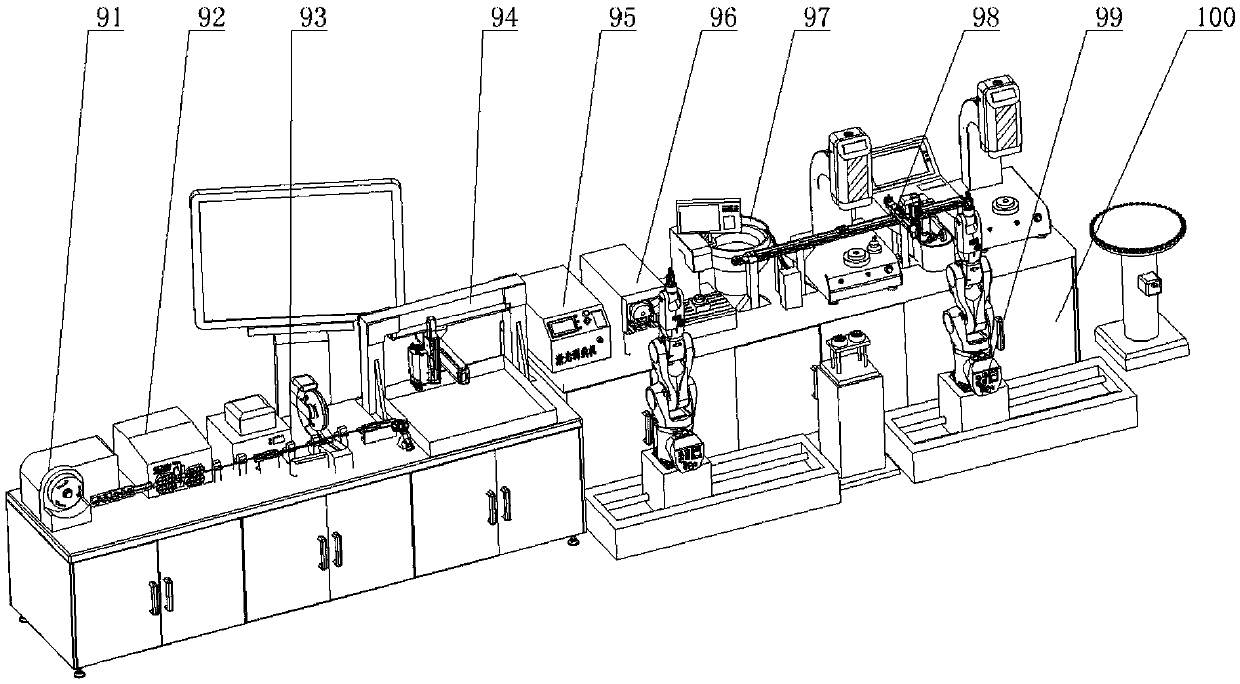

[0008] Such as figure 1 , figure 2 and image 3 As shown, a spring-guided thread-cutting mechanism of a low-frequency cable assembly crimping system includes a base 7, an electric push rod 8, a support plate 12, a fixing seat 11 and two sets of high-efficiency buffer guide mechanisms are installed on the side of the base 7. Cutter 9 is installed on the push rod end of push rod 8, and cutter groove 10 is offered on fixed seat 11, and cutter groove 10 is positioned at cutter 9 below, and cutter groove 10 can cooperate with cutter 9, and support plate 12 is two , the support plate 12 is located between the cutter 9 and the fixed seat 11, there is a gap between the two support plates 12, the gap between the two support plates 12 can allow the cutter 9 to pass through, and two sets of high-efficiency buffer guide mechanisms are respectively located on the cutter 9, the high-efficiency buffer guide mechanism includes a fixed mount 1, the fixed mount 1 is installed on the base 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com