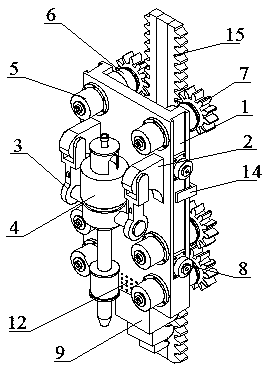

Gear rack drilling machine lifting device

A technology of rack and pinion, drilling rig, applied in the direction of support device, drill pipe, drill pipe, etc., can solve the problems of meshing and dislocation of the rack and pinion, achieve the effect of good meshing, large load and thrust, and reduce drilling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

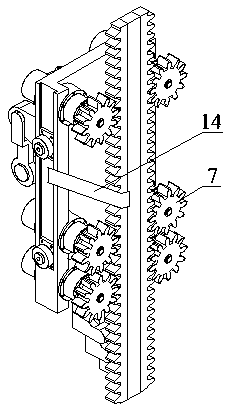

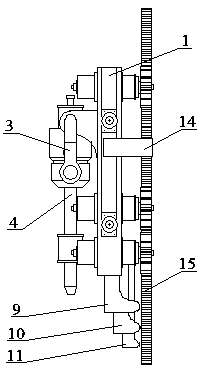

[0021] The rack and pinion drilling rig lifting device is composed of a mounting plate 1, a driver 4, a hydraulic motor 5, a reducer 6, a gear 7 and a straightener. There are multiple groups of hydraulic motors 5 and reducers 6 fixedly installed, gears 7 are installed on the reducers 6 through splines, drivers 4 are installed on the mounting plate 1 between the hydraulic motors 5 through symmetrically arranged fixed ears 2 and lifting rings 3 The guide rollers 8 are installed symmetrically on both sides of the mounting plate 1, and slide on the guide rail of the derrick through the guide rollers 8 to limit the operation of the lifting device, thereby ensuring that the lifting device will not deviate from the working space. 7-shaped hoops 14 are symmetrically arranged on the mounting plate 1 between the guide rollers 8 . The hoop 14 is slidably connected with the rack 15 on the derrick.

[0022] The lower end of the mounting plate 1 is equipped with a straightener through bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com