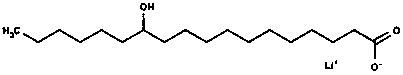

Preparation method of lithium 12-hydroxystearate

A technology of lithium dodecyl hydroxystearate and lauryl hydroxystearate, which is applied in the field of preparation of lithium stearate, can solve the problems of high free stearic acid, incomplete reaction of stearate, and low purity, and achieve Low cost, improved product purity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

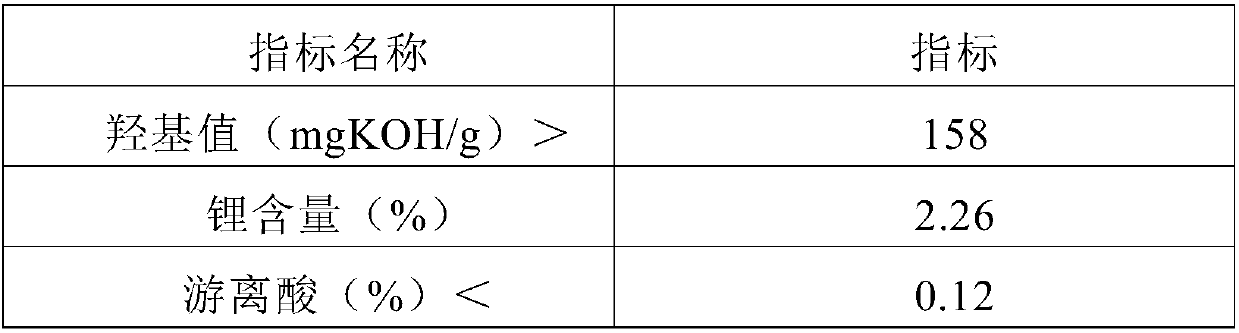

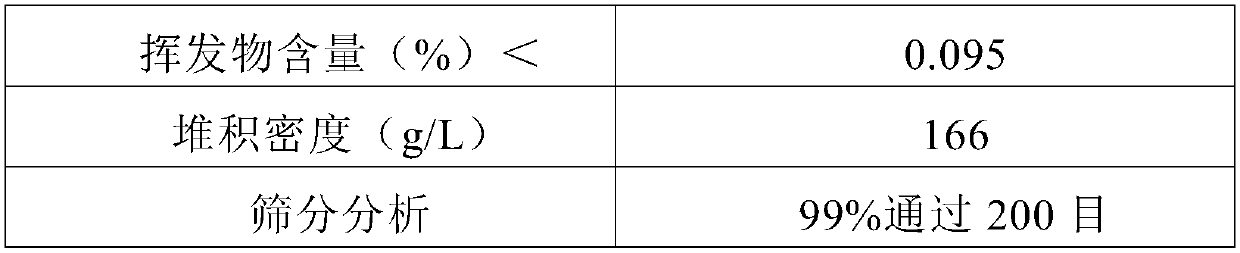

[0033] A kind of preparation method of lithium dodecyl hydroxystearate of the present invention, comprises the following steps: comprises the following steps:

[0034] A. Mix dodecyl hydroxystearic acid and water at a ratio of 1:10-1:5, raise the temperature of the prepared raw materials to 90°C-100°C to make lauryl hydroxystearic acid miscible in water, and heat the mixture at 90°C -100°C constant temperature for 40min-60min to obtain dodecyl hydroxystearic acid solution;

[0035] B. Mix lithium hydroxide monohydrate with water to form a lithium hydroxide solution with a mass percent concentration of 2.5%-10%, raise the temperature to 80°C-90°C, and keep the temperature at 80°C-90°C for 15min-30min to obtain hydroxide Lithium solution;

[0036] C, the lithium hydroxide solution obtained in the above-mentioned B step is added to the dodecyl hydroxystearic acid solution obtained in the above-mentioned A step according to the ratio of lithium hydroxide and dodecyl hydroxysteari...

Embodiment 1

[0057] A. Put 50g of dodecyl hydroxystearic acid with a main content of 97.51% in a beaker, add 500g of water, raise the temperature to 90°C to make dodecyl hydroxystearic acid miscible in water, and keep the temperature at 90°C for 60 minutes to obtain dodecyl hydroxystearic acid fatty acid solution.

[0058] B. Take 7.5g of lithium hydroxide monohydrate with a main content of 57.08% in a beaker, add 75g of water to dissolve it in water to form a 5.19% lithium hydroxide solution, raise the temperature to 90°C, and keep the temperature at 90°C for 15 minutes to obtain lithium hydroxide solution.

[0059] C. Add the 90°C mass percentage concentration of 5.19% lithium hydroxide solution prepared in step B to the lauryl hydroxystearic acid solution at 90°C obtained in step A at a molar ratio of 1.1 to carry out neutralization reaction , maintained at 90° C. and stirred for 40 minutes to obtain a reaction liquid.

[0060] D. Emulsifying the reaction liquid obtained in the above ...

Embodiment 2

[0068] A. Take 50g of lauryl hydroxystearic acid with a main content of 97.51% in a beaker, add 300g of water, heat up to 95°C to make lauryl hydroxystearic acid miscible in water, and keep the temperature at 95°C for 50 minutes to obtain lauryl hydroxystearin acid solution.

[0069] B. Take 7.5g of lithium hydroxide monohydrate with a main content of 57.08% in a beaker, add 157.5g of water to dissolve it in water to make a 2.59% lithium hydroxide solution, raise the temperature to 85°C, and keep the temperature at 85°C for 30 minutes until the hydroxide is oxidized lithium solution.

[0070] C. Add the 85°C mass percentage concentration of 2.59% lithium hydroxide solution prepared in step B to the 95°C lauryl hydroxystearic acid solution prepared in step A according to the molar ratio of 1.1 for neutralization reaction, and maintain Stir the reaction at 90° C. for 50 minutes to obtain a reaction liquid.

[0071] D. Emulsifying the reaction liquid obtained in the above step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com