Embossing device for tissue production

An embossing and paper towel technology, applied in the direction of mechanical processing/deformation, can solve the problem of dust pressing on the paper towel, etc., and achieve the effect of improving hygiene, processing efficiency and hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

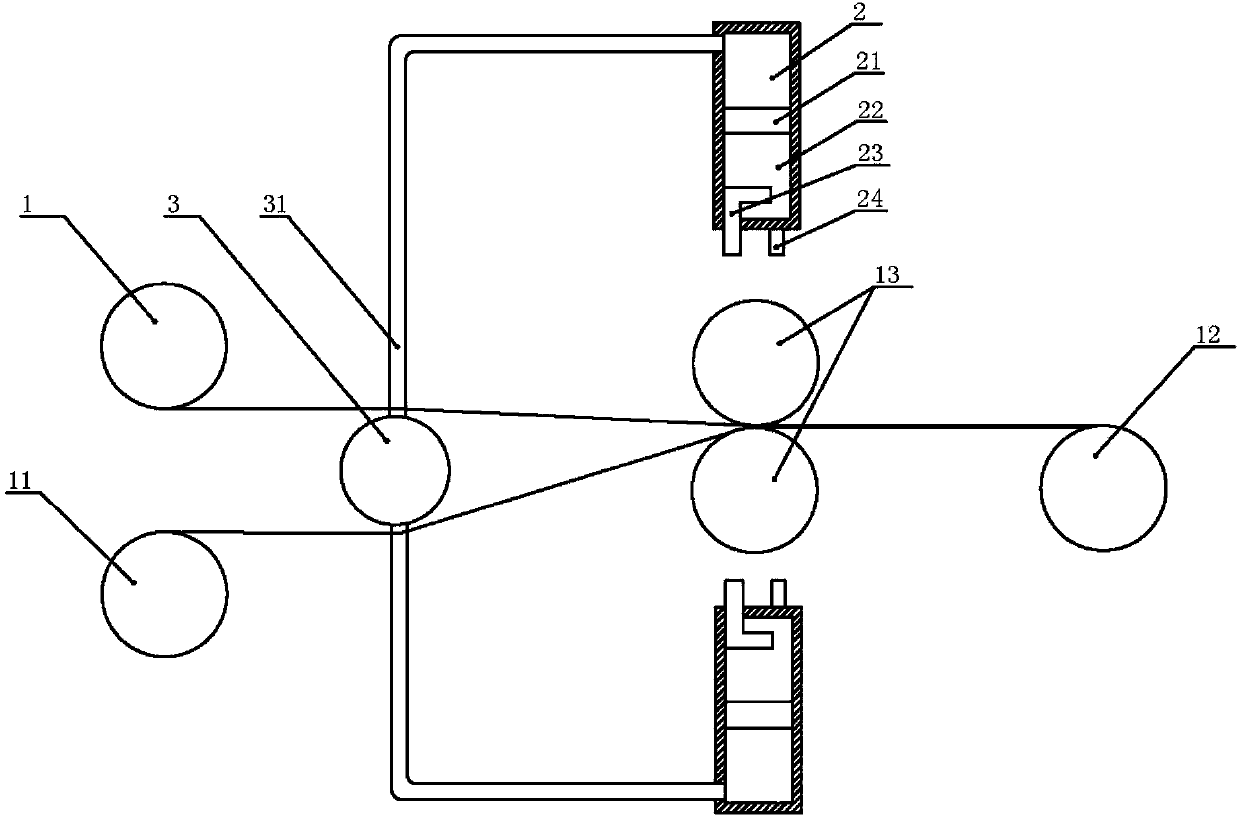

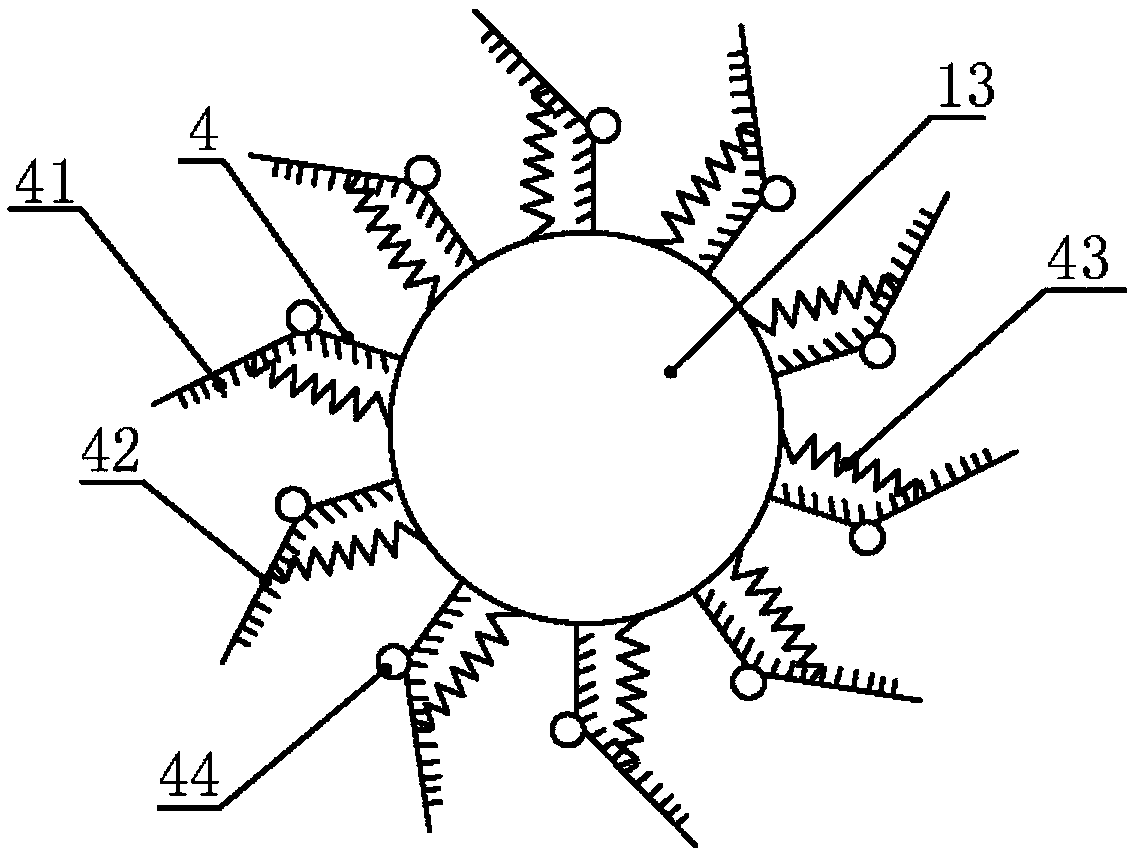

[0023] The reference signs in the accompanying drawings of the specification include: the first paper feed roller 1, the second paper feed roller 11, the paper delivery roller 12, the embossing roller 13, the gluing chamber 2, the piston 21, the dust collection chamber 22, the suction pipe 23, gear lever 24, rubber ball 3, rubber outlet pipe 31, support rod 4, fluff layer 41, driving lever 42, spring 43, magnet 44.

[0024] like figure 1 As shown, an embossing device for paper towel production in the present invention includes a first paper feed roller 1, a second paper feed roller 11 is installed below the first paper feed roller 1, the first paper feed roller 1 and the second paper feed roller The right side between 11 is rotated and is equipped with glue-coating ball 3, offers some holes on the glue-coating ball 3.

[0025] A pair of embossing rollers 13 are installed on the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com