Novel punching machine

A stamping machine, a new type of technology, applied in the field of stamping machines, can solve problems such as the inability to collect waste materials centrally, hinder equipment operation, and complex stamping structures, and achieve the effects of facilitating secondary processing, protecting the machine body, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

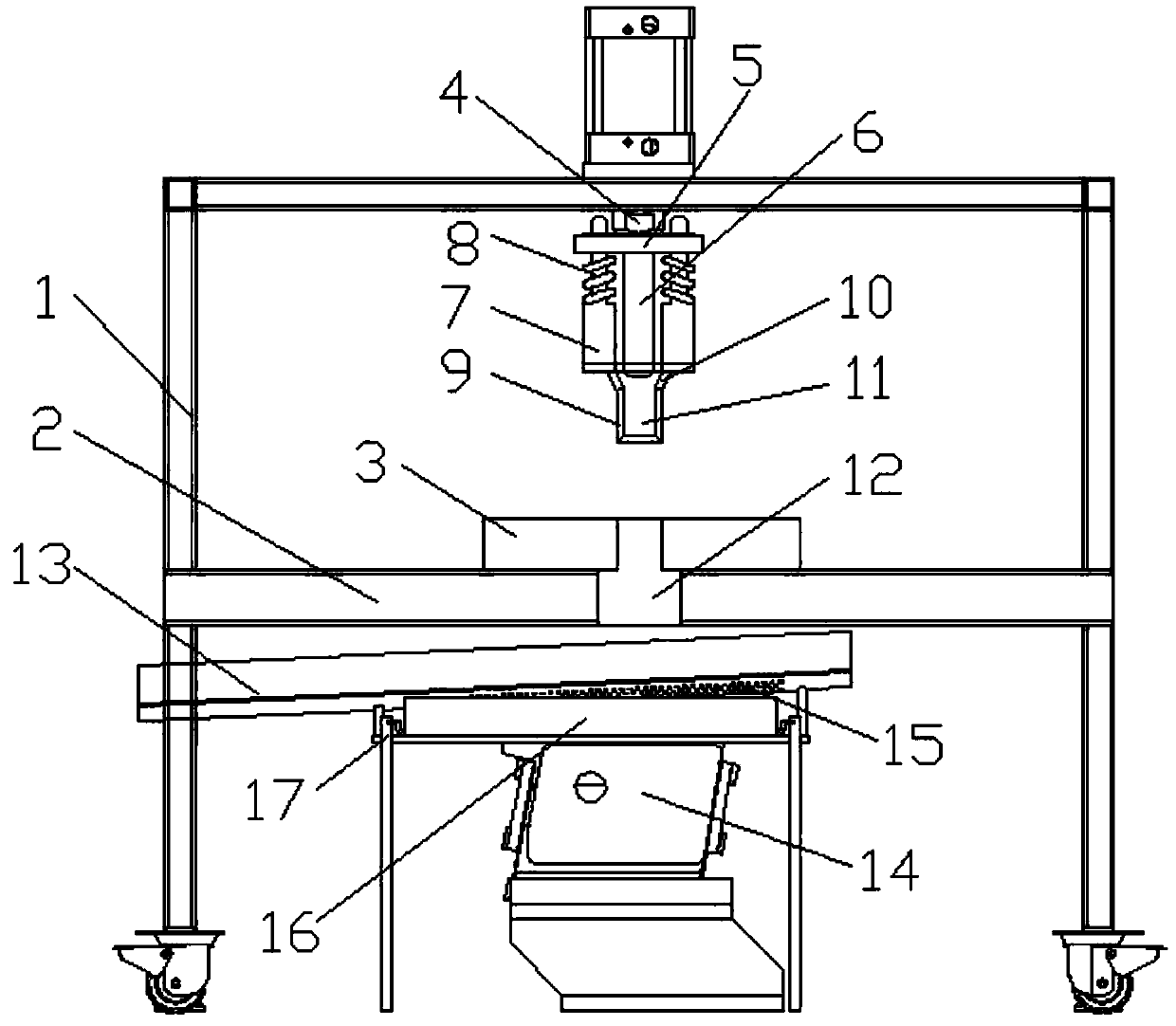

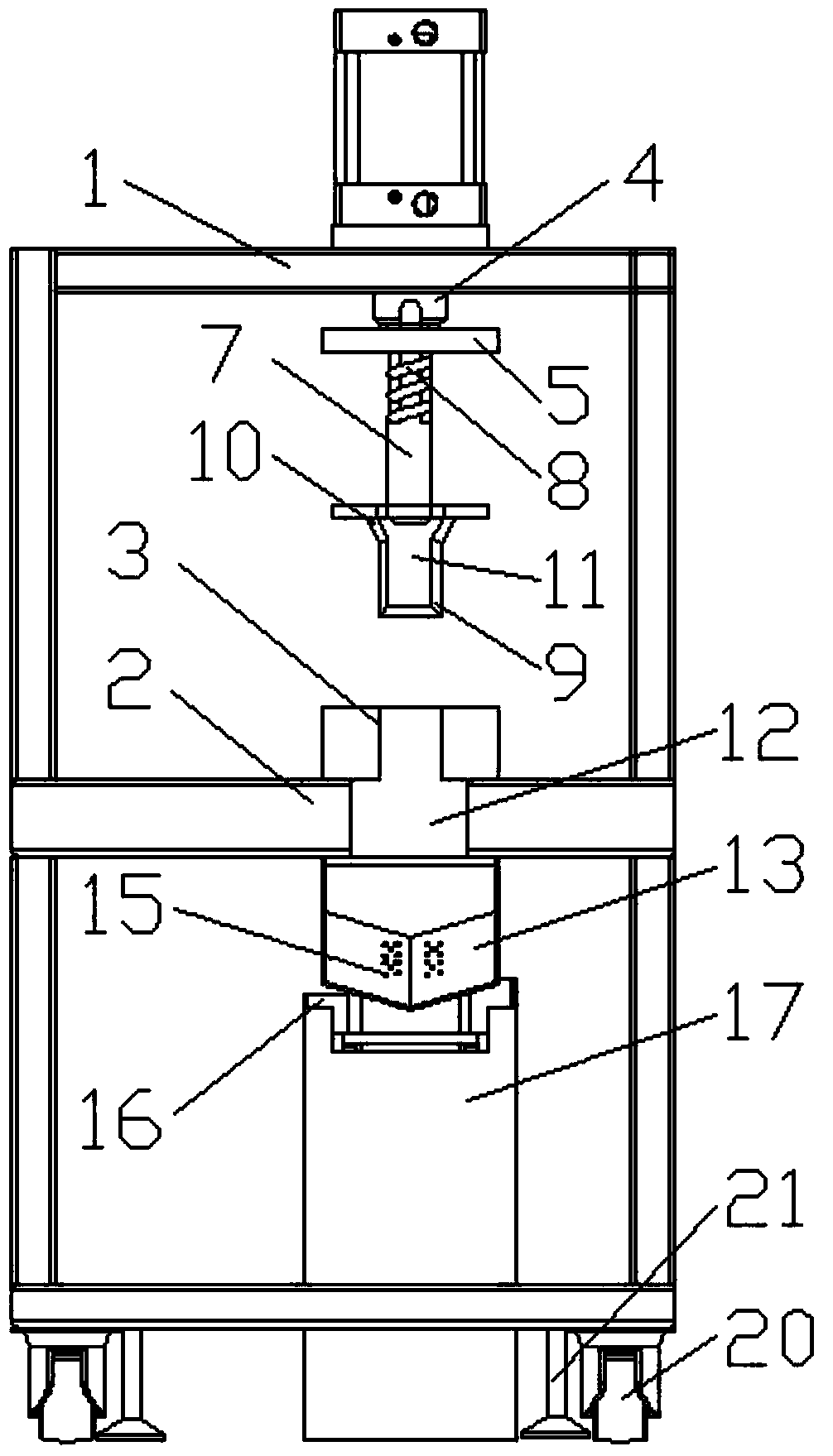

[0025] Such as figure 1 As shown, a new type of punching machine includes a frame 1, a working platform 2 is provided below the frame 1, and a punching rod 4 is provided above the frame 1, and the punching rod 4 is opposite to the working platform 2 A stamping plate 5 is provided at the end of the stamping plate 5, a fixed rod 6 is connected below the stamping plate 5, guide arms 7 are provided on both sides of the fixed rod 6, and the stamping plate 5 on both sides of the fixed rod 6 is provided with working holes , The upper end of the guide arm 7 passes through the working hole on the punching plate 5, the upper end of the guide arm 7 is provided with a limit part, and the guide arm 7 is located outside the lower part of the punching plate 5. Damping spring 8, the lower end of the guide arm 7 is connected with a punching tool 9, a funnel-shaped connecting tube 10 is also provided between the punching tool 9 and the guide arm 7, and a cavity 11 is provided in the punching tool...

Embodiment 2

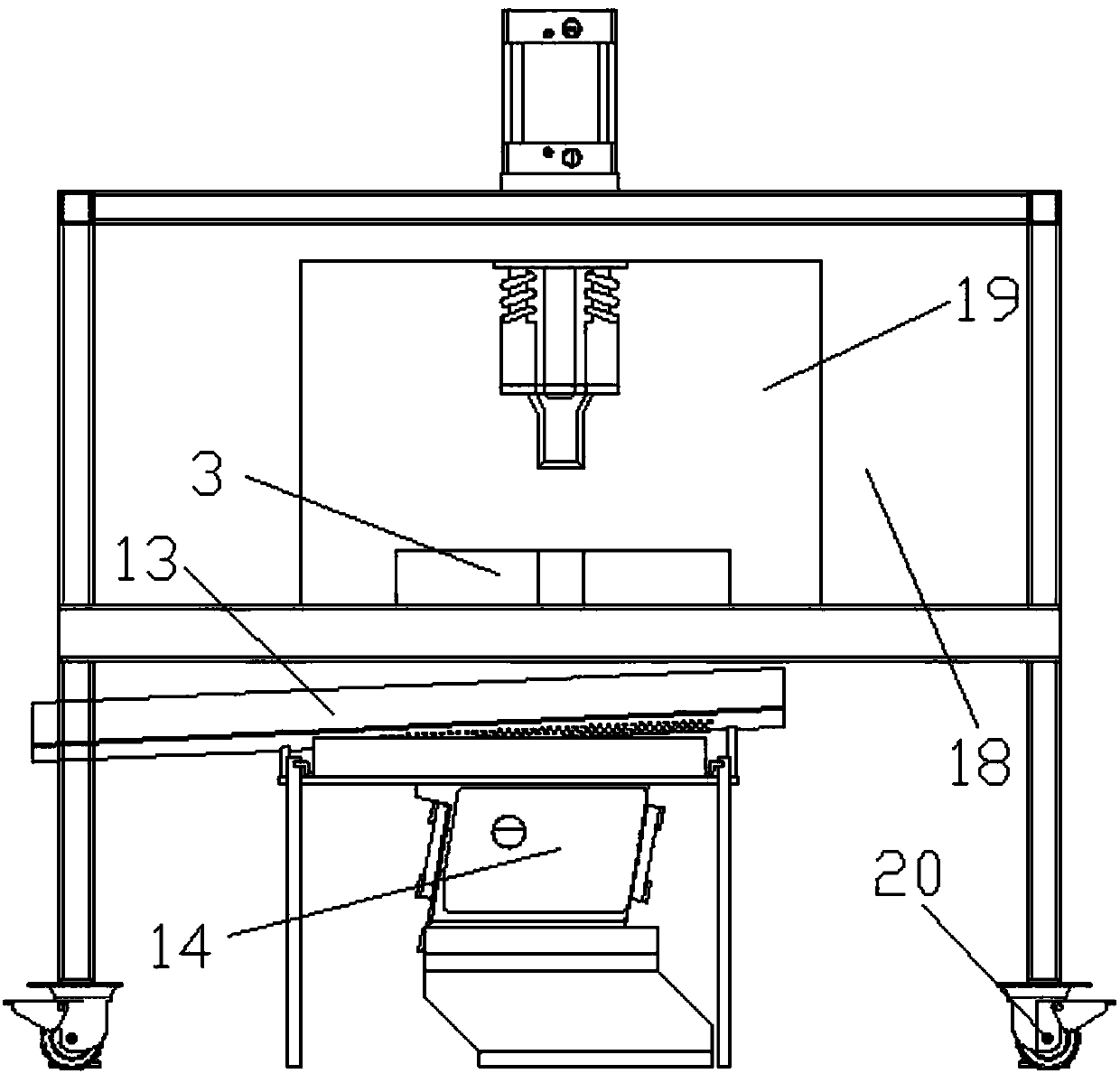

[0028] Such as image 3 As shown, on the basis of the first embodiment, in order to protect the safety of the operator, a safety baffle 18 is provided on the periphery of the rack 1, and a transparent observation window 19 is provided on the safety baffle 18. 18 can protect the operator from being scratched by the processing flying debris. At the same time, the transparent observation window 19 is convenient for observing the internal processing conditions. In order to facilitate the movement of the punching machine, the bottom four corners of the frame 1 are provided with stopperable casters 20. To further stabilize the press, an adjusting foot 21 is provided beside the caster 20, and a tapered anti-skid pad is provided at the lower end of the adjusting foot 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com