High-withstanding voltage subminiature electromagnetic relay

An electromagnetic relay, ultra-small technology, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems such as unfavorable loop resistance, increased difficulty, and shortened insulation distance, so as to simplify and use PCB design and improve the circuit Reliability, effect of reducing soldering requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

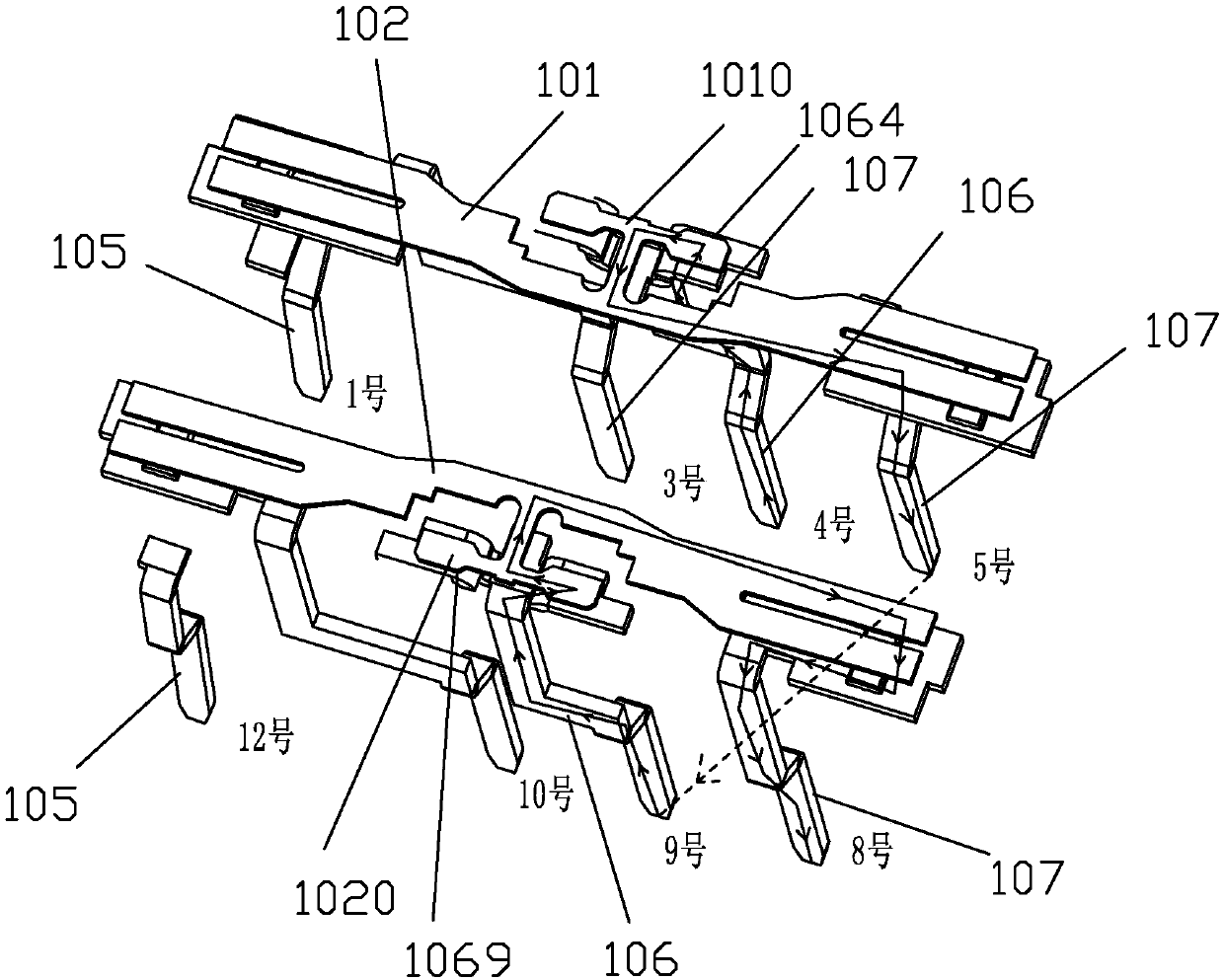

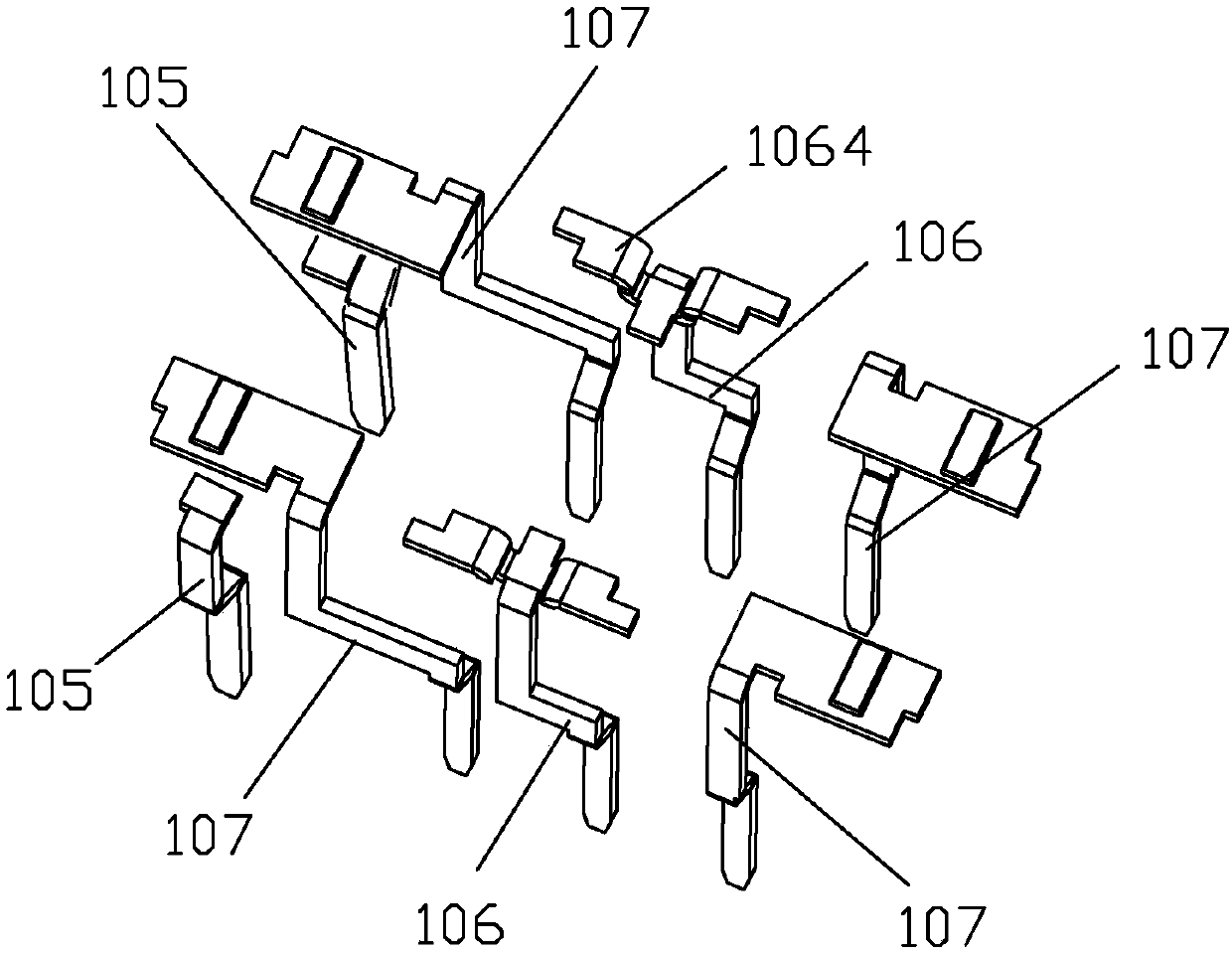

[0040] see Figure 6 to Figure 16 Shown, a kind of high withstand voltage ultra-miniature electromagnetic relay of the present invention comprises moving spring part and static spring part; Moving spring part comprises two moving springs namely moving spring 1, moving spring 2; Two moving springs 1,2 The first plastic body 5 formed by injection molding is insulated from the action magnetic conductor 3 and the permanent magnet 4 to form an integral action assembly; the two ends of each moving spring are respectively provided with a normally open end contact and a normally closed end contact. One end of the spring 1 is provided with a normally open contact 11, the other end of the movable spring 1 is provided with a normally closed contact 12, one end of the movable spring 2 is provided with a normally open contact 21, and the other end of the movable spring 2 is provided with a normally closed contact. End contact 22; static spring part comprises two normally open static spring...

Embodiment 2

[0052] see Figure 17 As shown, a kind of high withstand voltage ultra-small electromagnetic relay of the present invention differs from Embodiment 1 in that there are two connectors 7, and the middle parts of the two moving springs 1 and 2 are respectively provided with The notch disconnects between the normally open end contact and the normally closed end contact of each moving spring, and the two connectors 7 are connected between the two moving springs 1 and 2 at the two ends of the notch respectively, so that the two moving springs The normally open contacts are communicated with the normally closed contacts of the two moving springs, that is, one of the connectors 7 is connected between the two moving springs 1, 2, so that the two moving springs 1, 2 The normally open end contacts 11, 21 of 2 are connected, and another connecting body 7 is connected between the two moving springs 1, 2, so that the normally closed end contacts 12, 22 of the two moving springs 1, 2 connec...

Embodiment 3

[0056] see Figure 19 As shown, a kind of high withstand voltage ultra-small electromagnetic relay of the present invention differs from Embodiment 1 in that the permanent magnet 4 is one and is arranged along the axis direction of the moving magnetic conductor; the permanent magnet 4 Among them, a groove 42 constituting the abdication portion is provided at a position corresponding to the crossing of the connecting body, and the opening of the groove 42 faces the connecting body 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com